Fast heat-up of a thermal conditioning device e.g. for coffee machine

A technology for thermal regulation and heaters, applied in beverage preparation devices, applications, household appliances, etc., can solve the problems of bulky devices, loss of temperature accuracy, and uncontrollability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The following description of an exemplary embodiment of the invention relates to an electrical device for preparing beverages.

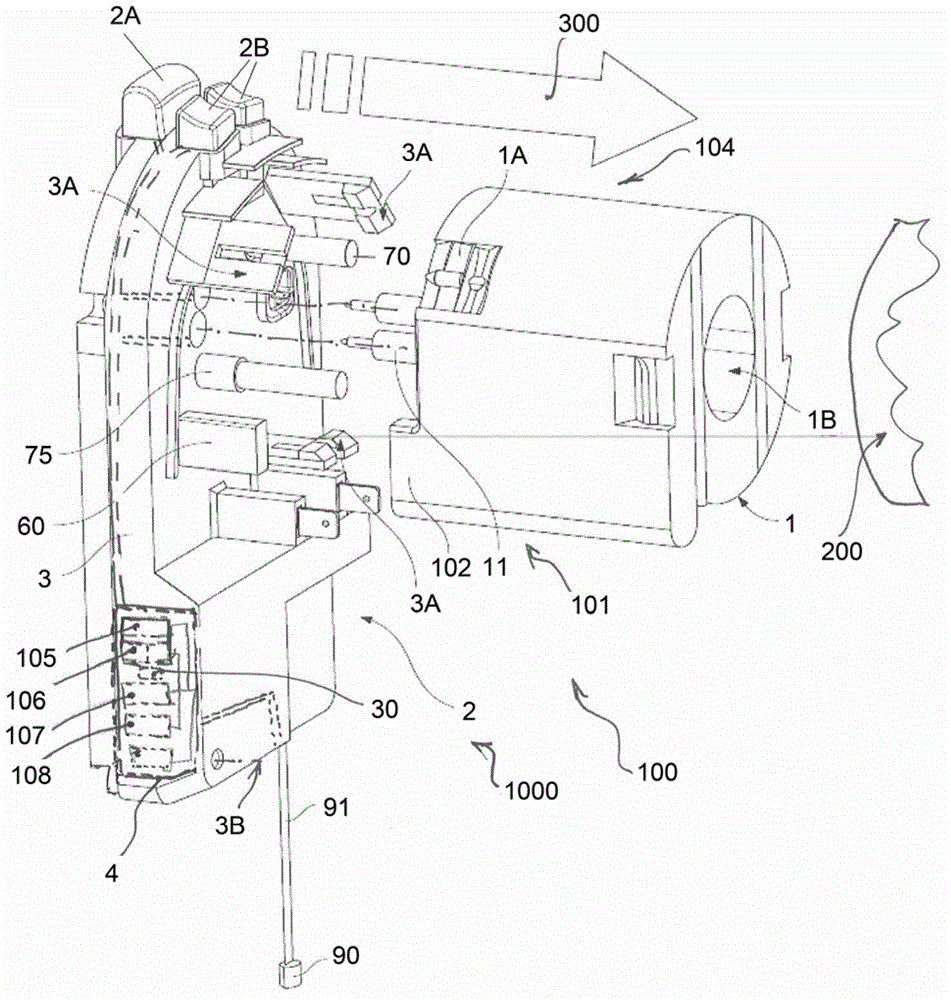

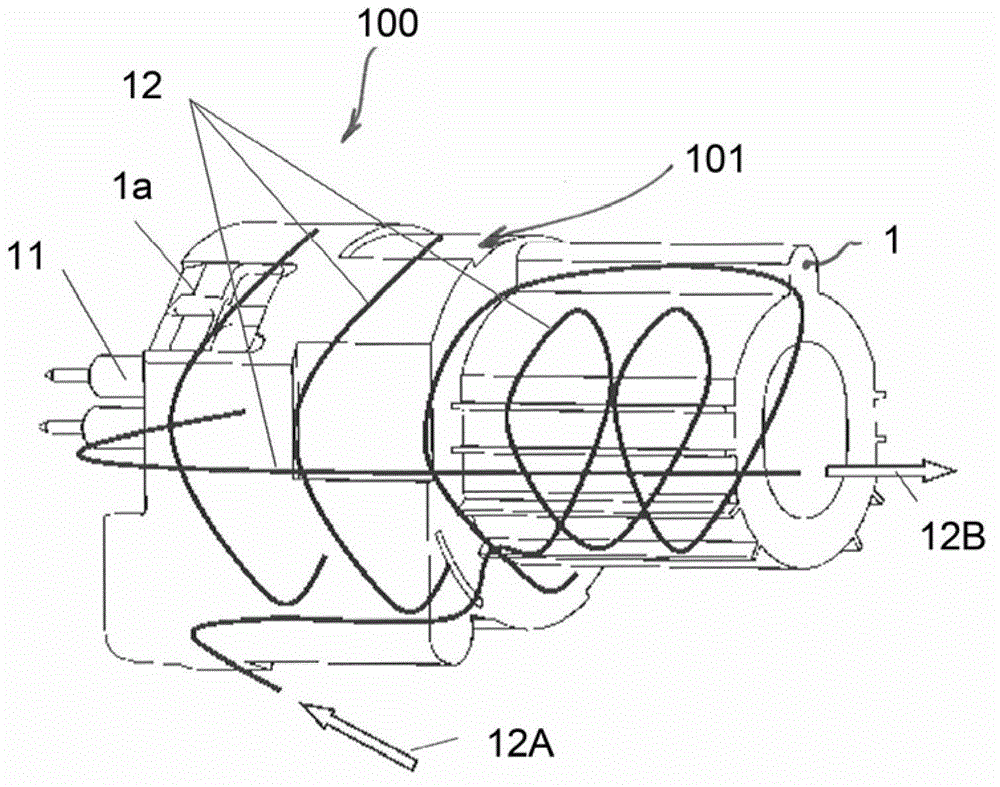

[0076] figure 1 Shown is an apparatus 1000 for controlling power delivery to a thermal conditioning device 100, such as a heater or cooler, comprising:

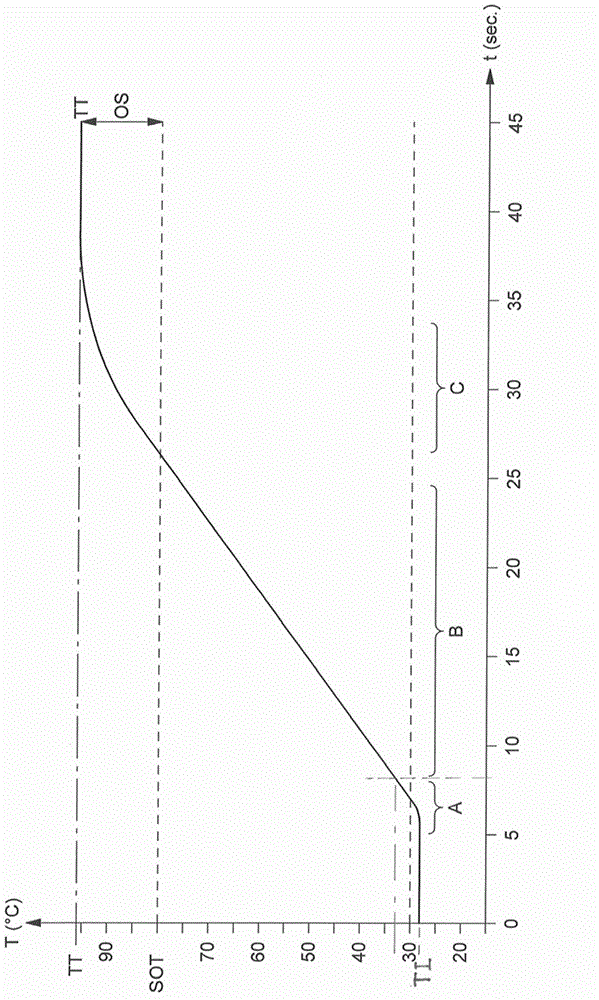

[0077] - a controller 2 having a start-up procedure for starting the thermal regulation device 100 from an inoperative temperature TI to an operating temperature in order to bring the fluid flowing through said thermal regulation device 100 to a target temperature TT at the end of the start-up, and

[0078] - A temperature sensor 70 connected to said controller 2 for determining the temperature of the fluid flowing through said thermal regulation device 100 .

[0079] The controller 2 is arranged to enable fluid to flow through the thermal regulation device 100 at the end of the start-up and to compare the measured temperature SOT of the flowing fluid at the end of the start-up with a prede...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com