Stranding lead in device of stranding machine

A leading-in device and stranding machine technology, applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of increasing production processes, unfavorable stranding process requirements, and low production efficiency, so as to improve utilization and production efficiency , high-quality stranding process requirements, and the effect of uniform pitch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

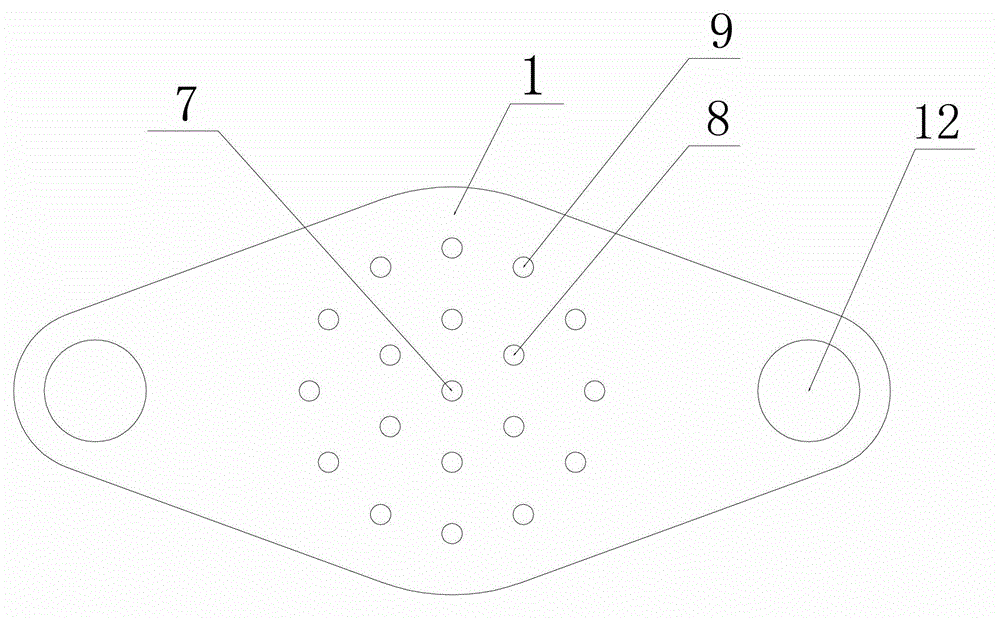

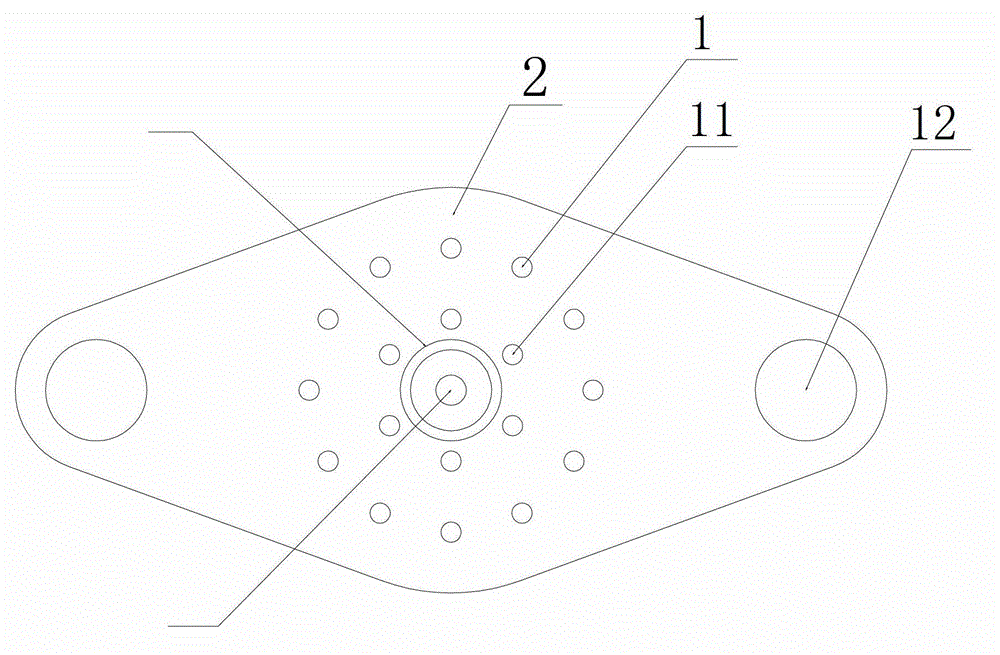

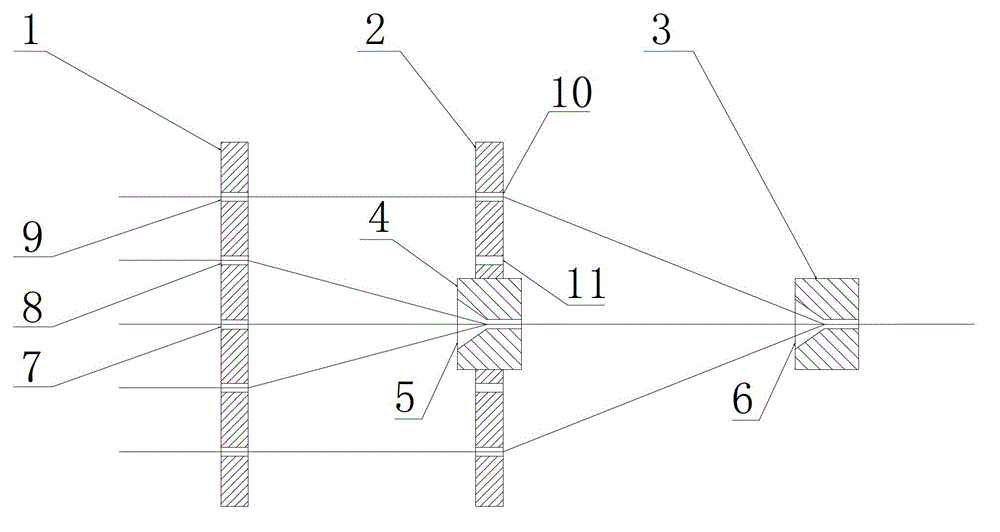

[0017] Such as figure 1 , 2 , 3, and 4, a twisting introduction device of a stranding machine is provided with a first branching template 1, a second branching template 2, and a second paralleling die set 3 along the incoming line direction, and the second branching The center of the line formwork 2 is provided with a first paralleling die set 4, and the first paralleling die set 4 and the second paralleling die set 3 are respectively provided with a first paralleling hole 5 and a second paralleling hole 6, and A branch template 2 is provided with the threading holes equivalent to the total number of required conductors for stranding, wherein the threading holes are composed of main threading holes 7, some first inner threading holes 8 and some first outer threading holes 9, the main threading holes 7 Located at the center of the first bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com