Rotational flow untwisting device used for Z-twist special yarn

An untwisting and yarn technology, applied in the field of swirl untwisting air splicer, can solve the problems of increased cost, reduced service life, easy deformation, etc., to improve the stability and reliability of use, reduce maintenance and Maintenance cost, effect of less deformation and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

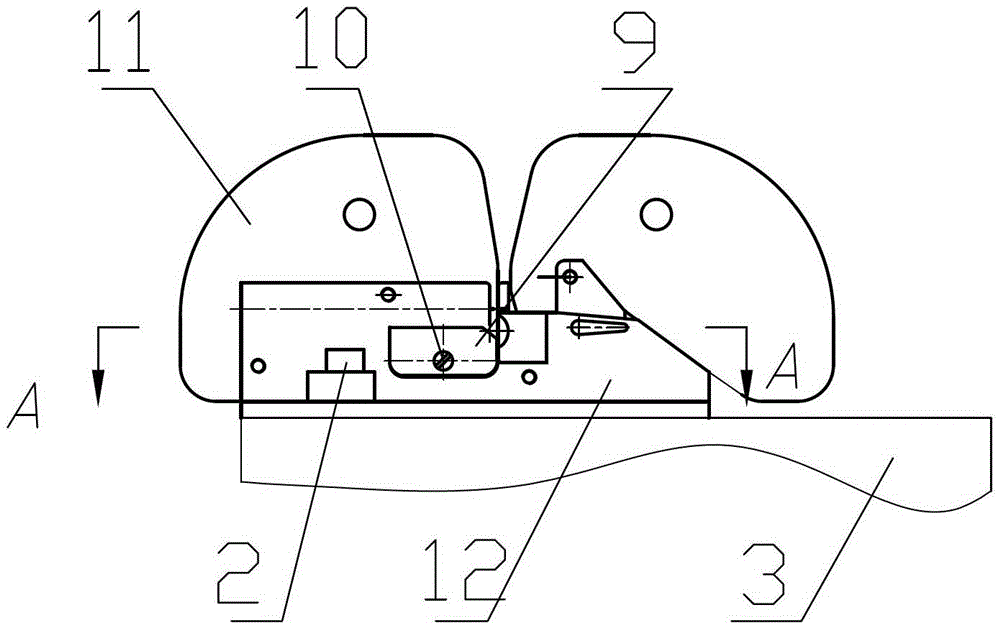

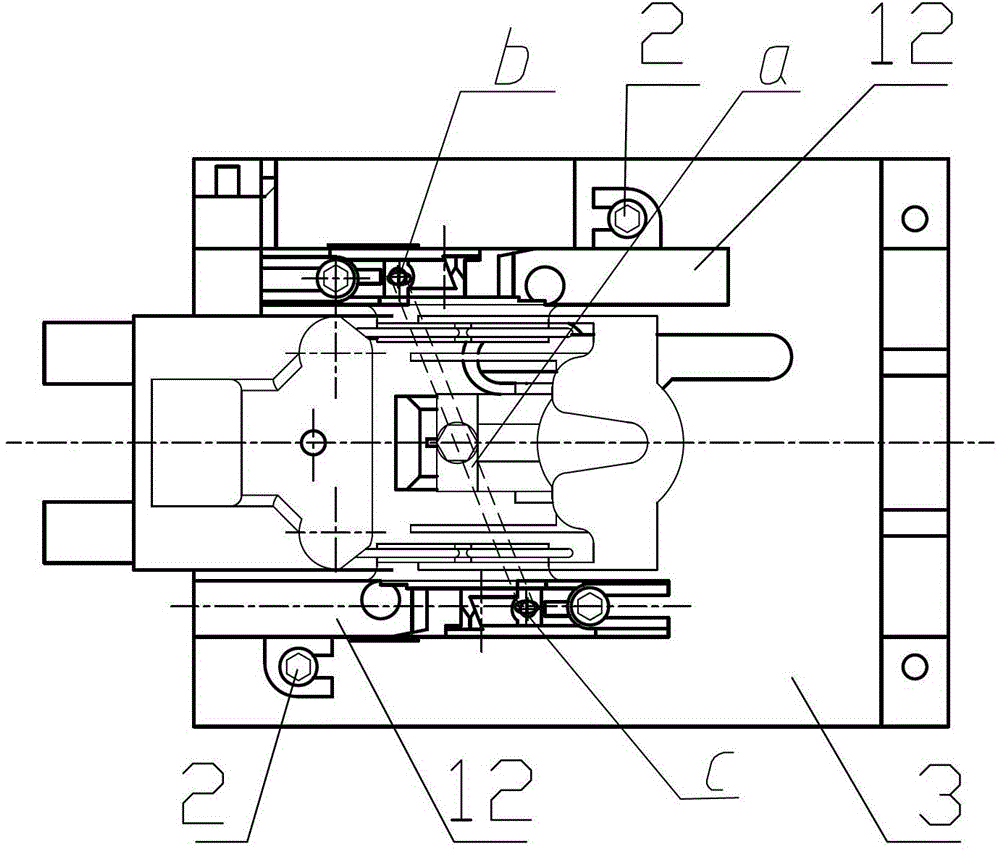

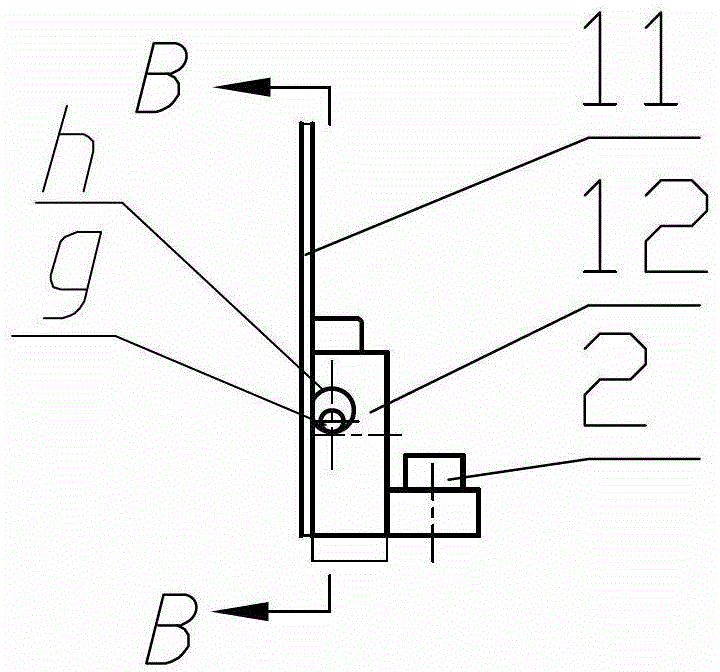

[0014] Figure 1~Figure 5 Including injection hole blocking column 1, fixing bolt 2, upper casing 3, gasket 4, O-ring 5, untwisting fiber 6, guide plate fixing screw 7, positioning pin 8, baffle 9, baffle fixing Screw 10, yarn guide plate 11, body 12, feeding groove 13, etc.

[0015] Such as Figure 1~Figure 3 As shown, the present invention is a swirling untwisting device for Z-twisted special yarns, including a body 12, which is fixed on the upper housing 3 of the air splicer by fixing bolts 2, and is located on the yarn guide plate 11, the yarn guide plate 11 is fixed on the body 12 by the yarn guide plate fixing screw 7.

[0016] Such as Figure 3~Figure 5 As shown, the body 12 is made of a metal material, preferably a zinc alloy integrally die-cast. The upper part of the main body 12 is provided with a horizontal untwisting hole h,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com