Anti-rolling decoupling mechanism of magnetic levitation vehicle walking unit

An anti-roll decoupling mechanism and magnetic levitation technology, which is applied in the direction of railway car body parts, track contact elements, bogies, etc., can solve the problem of increasing the gap between modules and track design, reducing suspension and traction efficiency, and reducing anti-roll capacity, etc. problem, to achieve the effect of improving the ability to pass through the curve, improve the decoupling ability, and increase the speed of the curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

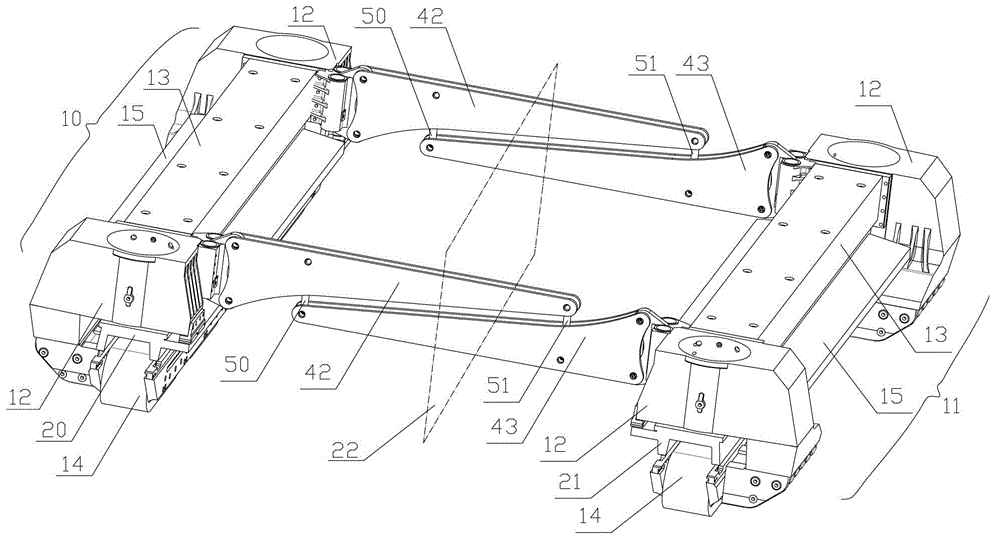

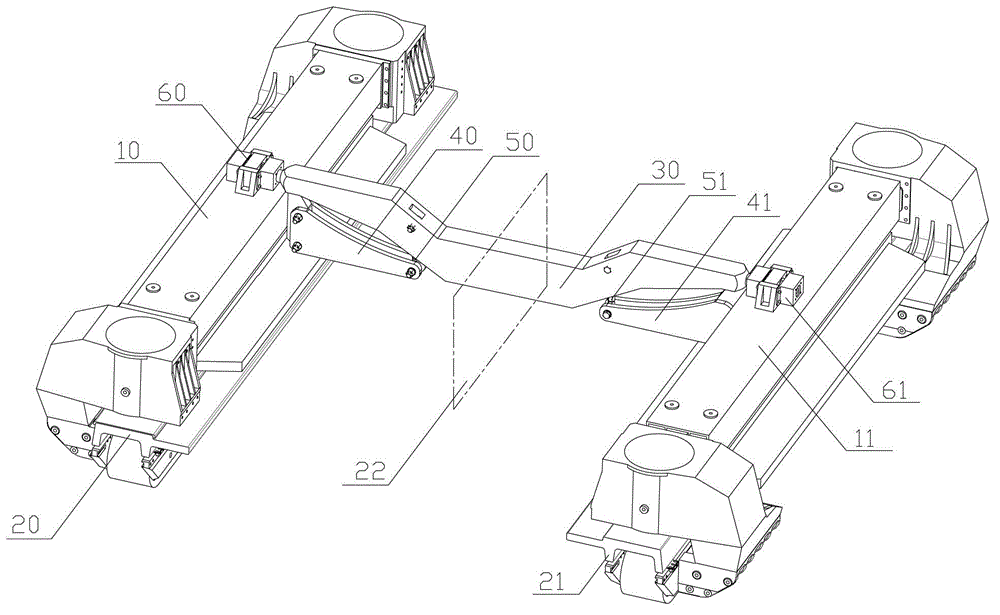

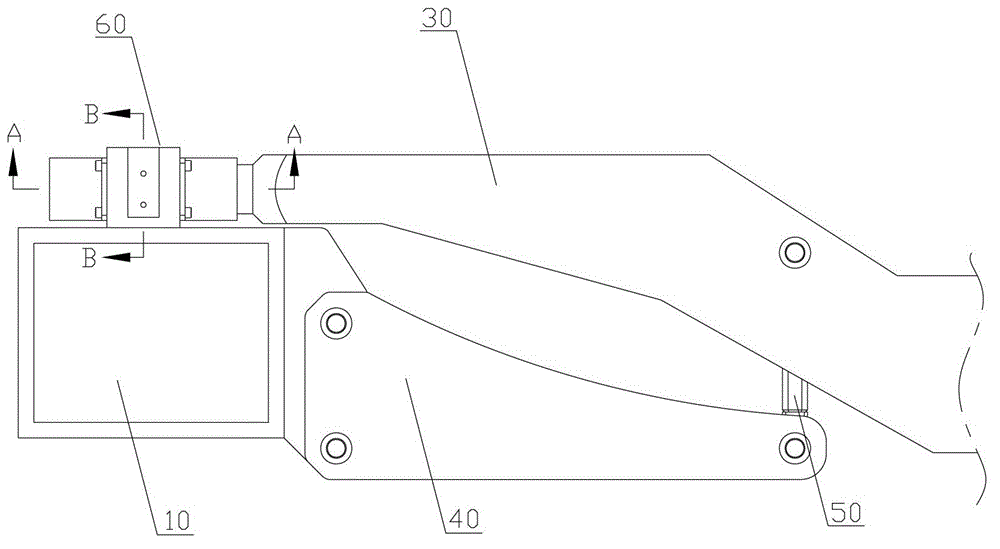

[0026] figure 2It is a schematic diagram of the installation of the present invention on the running unit of the suspended vehicle. The anti-roll decoupling mechanism of the running unit of the magnetic levitation vehicle provided by the present invention is composed of a center beam 30, two anti-roll beams, two suspenders and two sets of spherical hinge linear combined bearings, which are arranged on the running unit along the vertical track direction On the middle section of the track, it is integrated with two suspension modules arranged left and right along the direction of the track, forming an "H"-shaped layout. One end of the left anti-roll beam 40 in the two anti-roll beams is fixedly connected to the left suspension module 10 at the middle section position, and the other end is connected to the lower end of the left suspender 50 through a ball joint; one end of the right anti-roll beam 41 is connected to the right suspension module 11 in the The middle section posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com