Engagement rotor of internal mixer

An internal mixer and meshing technology, which is applied in the field of meshing rotors of internal mixers, can solve the problems of increasing the axial force and resistance torque of the rubber on the rotor, increasing the rubber mixing cycle, and deteriorating the end face seal, so as to improve the rubber mixing. quality, shorten the mixing cycle, and enhance the effect of meshing friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

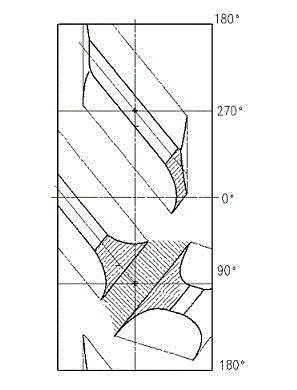

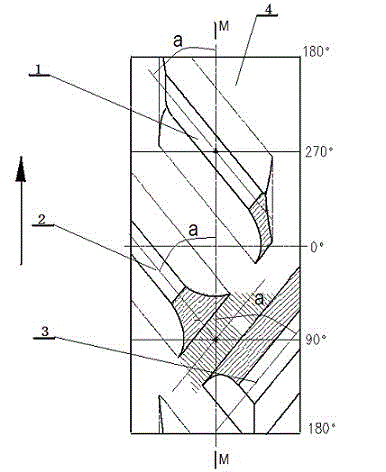

[0012] like figure 2 As shown, the intermeshing rotor of the internal mixer of the present invention includes a rotor body 4 and three ribs arranged on the rotor body 4, which are respectively the long rib 1, the middle rib 2 and the short rib 3, figure 2 The middle arrow indicates the rotation direction of the rotor. The helical direction of the long rib 1 and the middle rib 2 is the same. The helical direction of the short rib 3 is opposite to that of the long rib and the middle rib. When the rotor is working, the rubber can return to the middle of the rotor for further processing. Further turning back, stirring, and mixing, the helix angle a of the long edge 1 and the middle edge 2 is close, and the helix angle a of the short edge 3 is greater than the helix angle a of the long edge 1 and the middle edge 2. On the middle section of the rotor body 4 (Fig. Middle M-M), the section phase difference between the long edge and the middle edge is 180°, and the phase difference b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com