Vacuum cleaner having an external-air valve for filter cleaning

A technology for external air and vacuum cleaners, which is applied in the direction of cleaning filter devices, valve operation/release devices, valve devices, etc., which can solve the problems that the suction operation of vacuum cleaners is no longer guaranteed, and achieve enhanced cleaning effect and high-efficiency cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

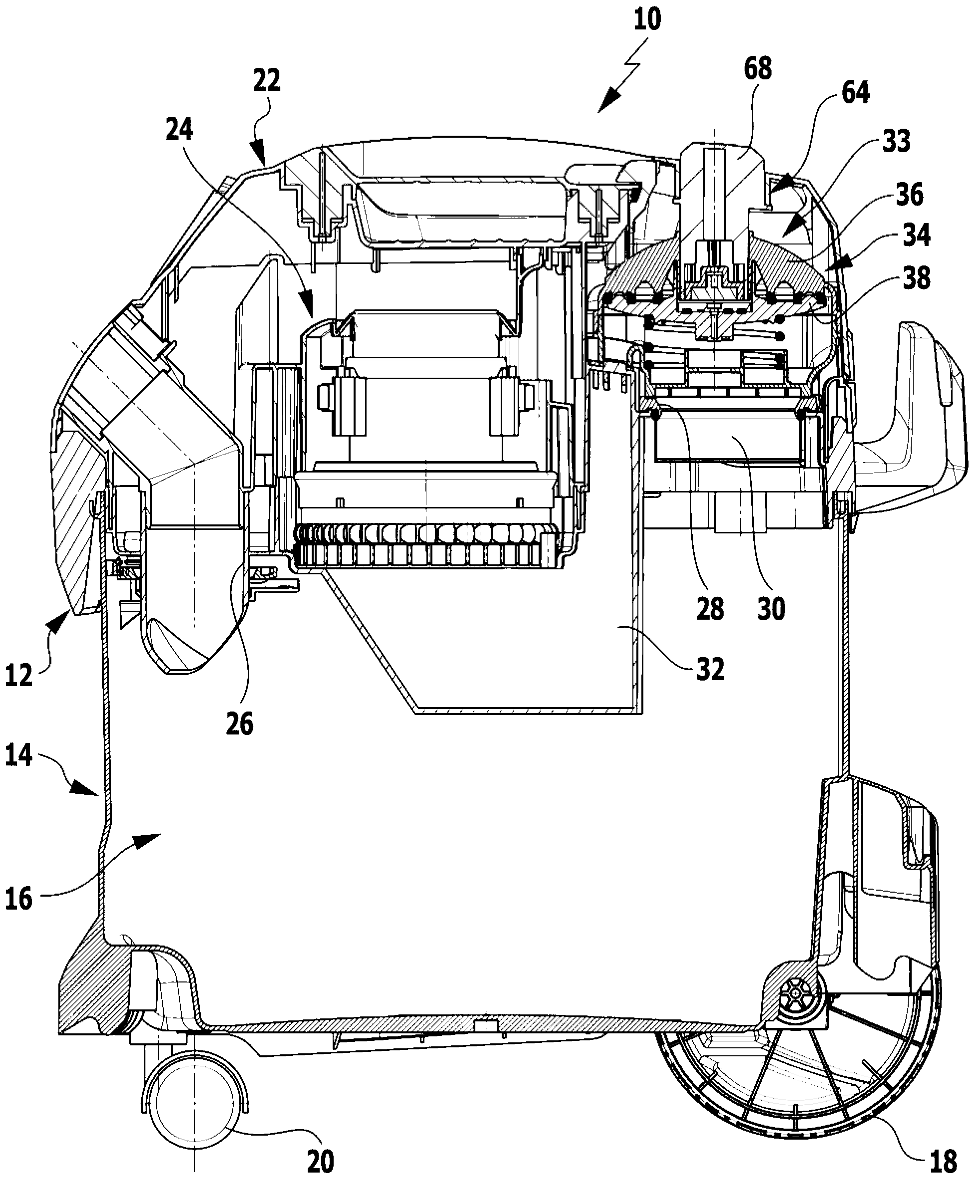

[0035] A vacuum cleaner 10 is shown schematically in the drawing with a two-part housing 12, the lower part 14 of which is configured as a dirt collection container 16 and can be moved by means of rollers 18 and pivoting rollers 20, Furthermore, the upper part 22 of the housing can be pushed onto the lower part 14 and accommodate the suction unit 24 . The dirt collection container 16 includes a suction inlet 26 , to which a conventional suction hose (not shown in the drawing) can be connected. The suction hose can carry a suction nozzle at its free end, which can be guided along the surface to be sucked off, for example the floor. Alternatively, it can be provided that the suction hose is connected to a processing tool, for example a drilling unit or a milling unit, so that dust accumulated during operation of the processing tool can be suctioned off.

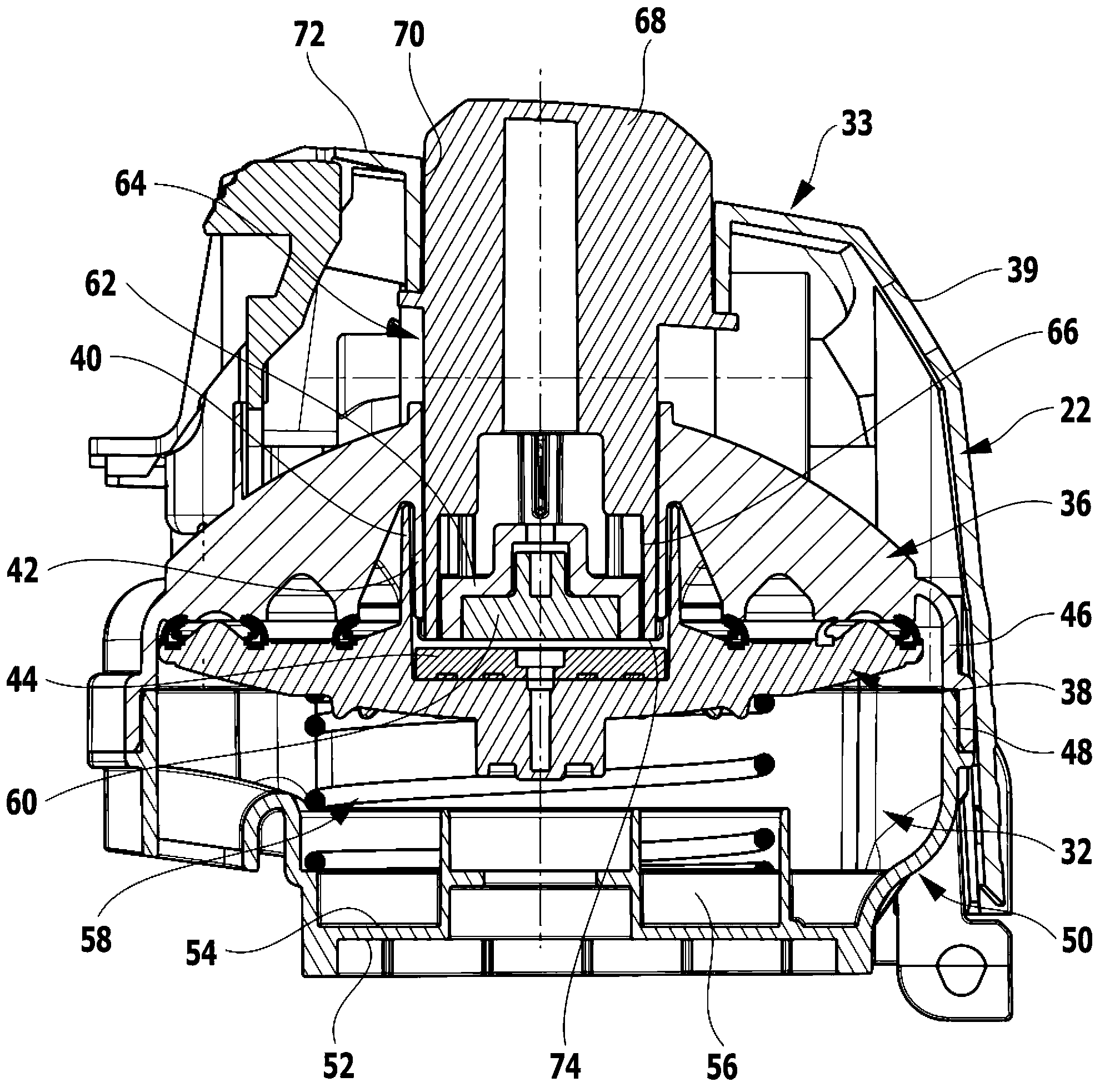

[0036] The upper part 22 forms a suction outlet 28 for the dirt collection container 16 . At the suction outlet 22 is held ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com