Fast wiring module capable of being connected parallelly

A fast, wiring hole technology, applied in the direction of connection, conductive connection, clamping/spring connection, etc., can solve the problems of large installation space and low wiring efficiency, and achieve the effect of reducing installation space, saving space, and compact wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

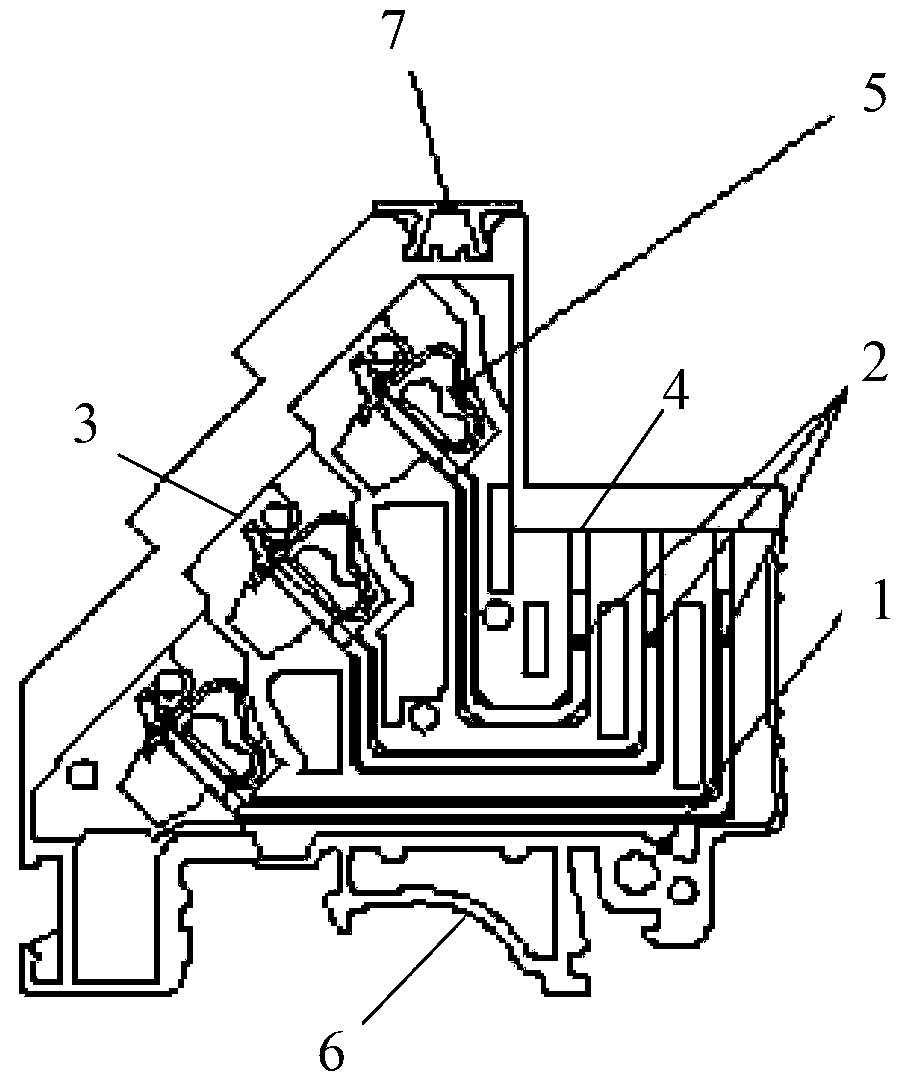

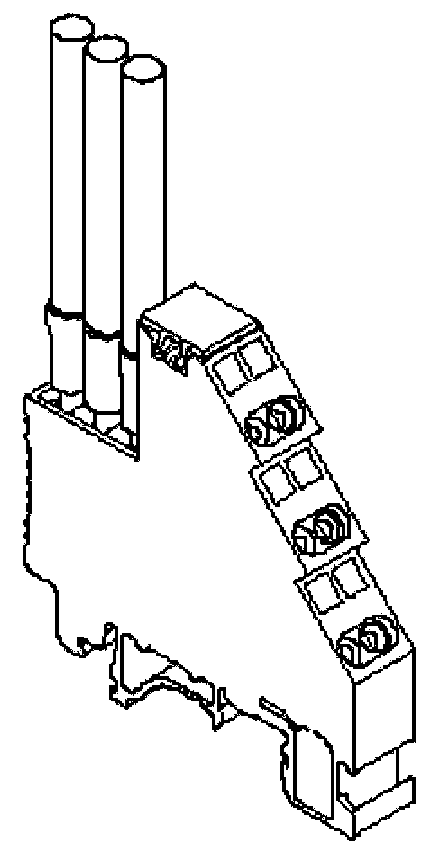

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a parallel fast wiring module of the present invention includes an insulating housing 1 and at least one conductor 2, and a plurality of insulating grooves are arranged on the inner side of the insulating housing 1, wherein the insulating housing 1 At least one first wiring hole 3 and at least one second wiring hole 4 are provided, the first wiring hole 3 and the second wiring hole 4 are all located in the same plane, the axis of any first wiring hole 3 The axial direction of any one of the second wiring holes 4 intersects at an acute angle, and any one of the first wiring holes 3 communicates with a second wiring hole 4 through a tunnel formed by an insulating groove, and each of the tunnels is respectively provided with There is one conductor 2, and a cage spring terminal 5 is arranged in any one of the first connection holes 3, and any one of the cage spring term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com