Novel carbon tank structure

A carbon canister, a new type of technology, is applied in the direction of adding non-fuel substances, engine components, machines/engines, etc. to the fuel, and can solve problems such as the blockage of the canister vent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

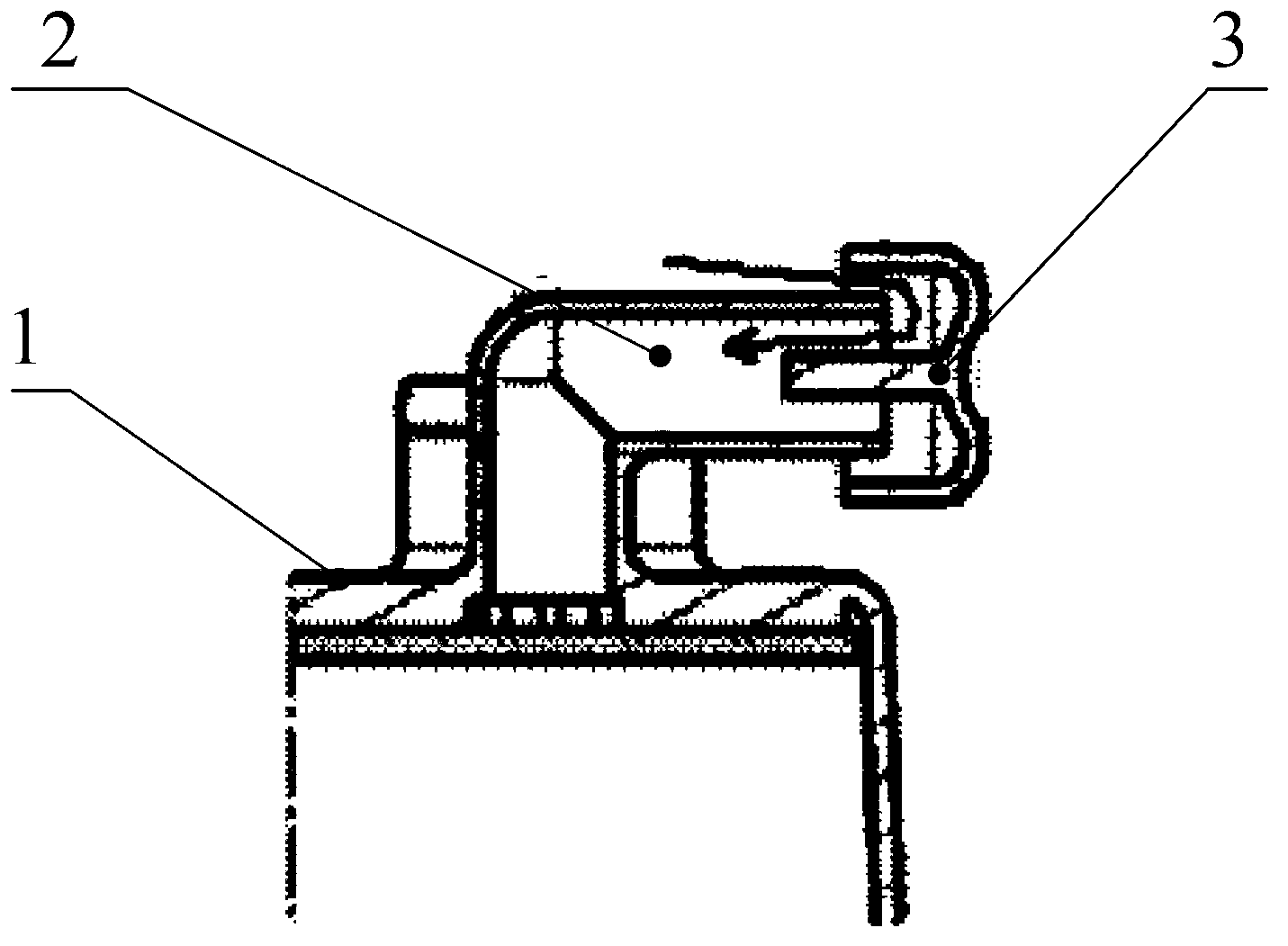

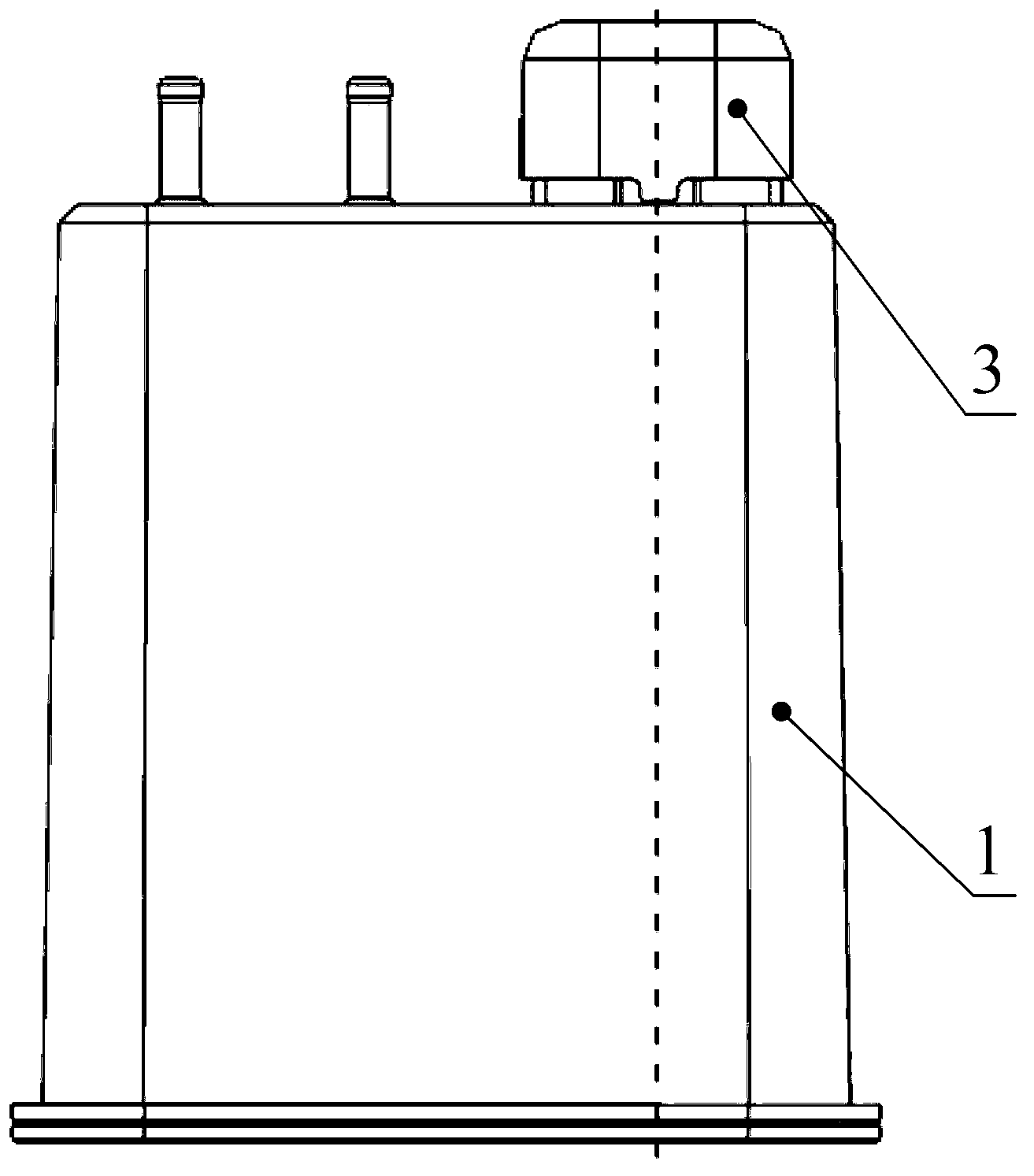

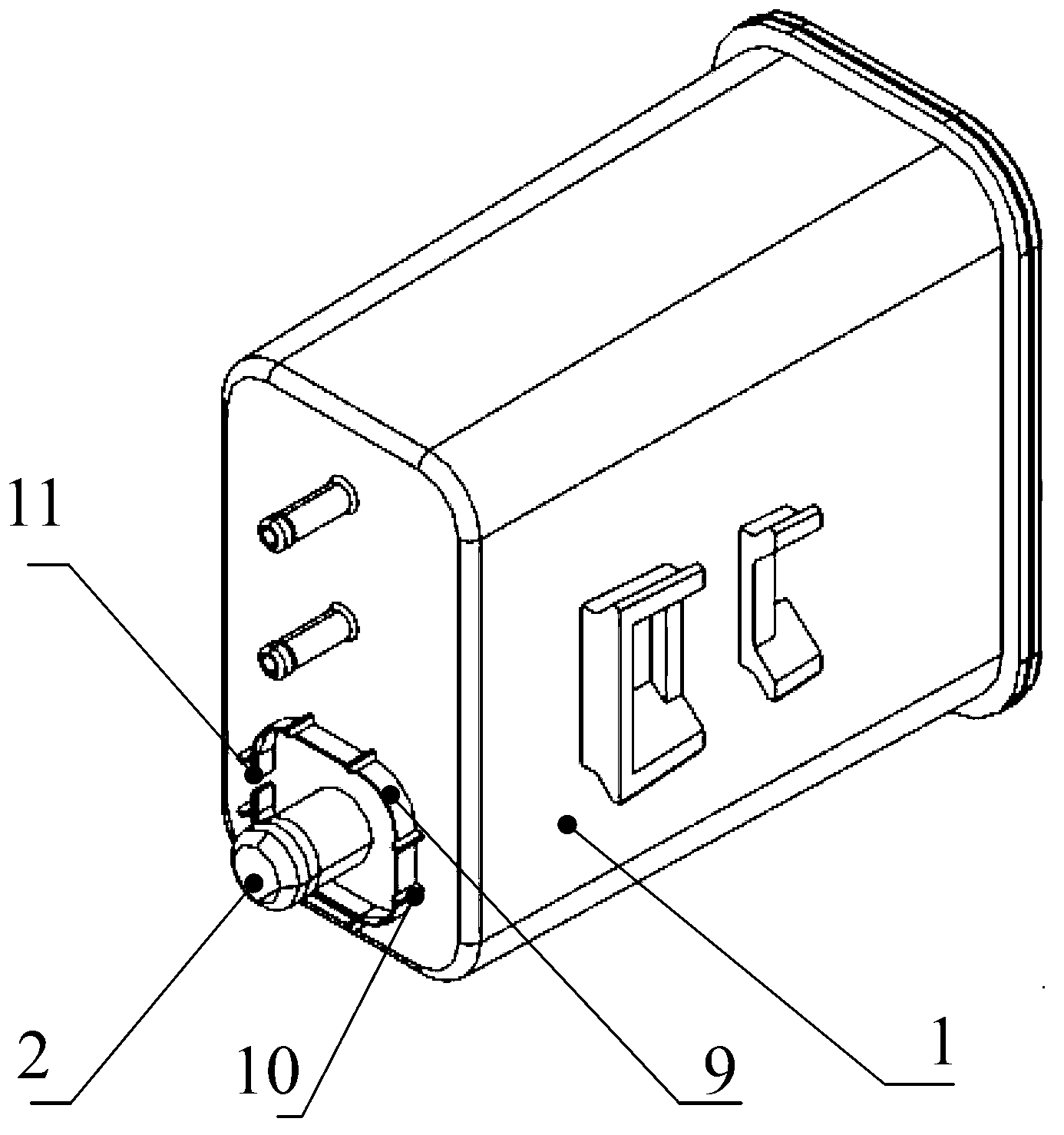

[0027] Such as Figure 2-5 A new type of carbon canister structure of the present invention is shown, comprising a canister main body 1, which is provided with a vent 2 communicating with the outside air, and also includes a protective cap 3, which is covered on the vent opening. Above; the central part of the protective cap is also protrudingly provided with buckle 6, and the buckle stretches into the air vent, and the protective cap is fastened with the air vent through the buckle, which ensures that the protective cap does not stop when the vehicle is running under various working conditions. will fall off. A filter element 4 is arranged along its inner wall in the protective cap, and a protruding filter element support structure 5 is also provided at the cover bottom of the protective cap. The filter element support structure clamps the filter element in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com