Cylinder cover casting production sand treatment regeneration material control screening device

A technology for casting production and screening device, which is applied to the cleaning/processing machinery of casting materials, casting molding equipment, filter screens, etc., can solve the problems of uneven feeding at the feeding port, old molding sand clogging the vibrating screen, etc. To achieve the effect of simple structure, purification of production working environment and uniform feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

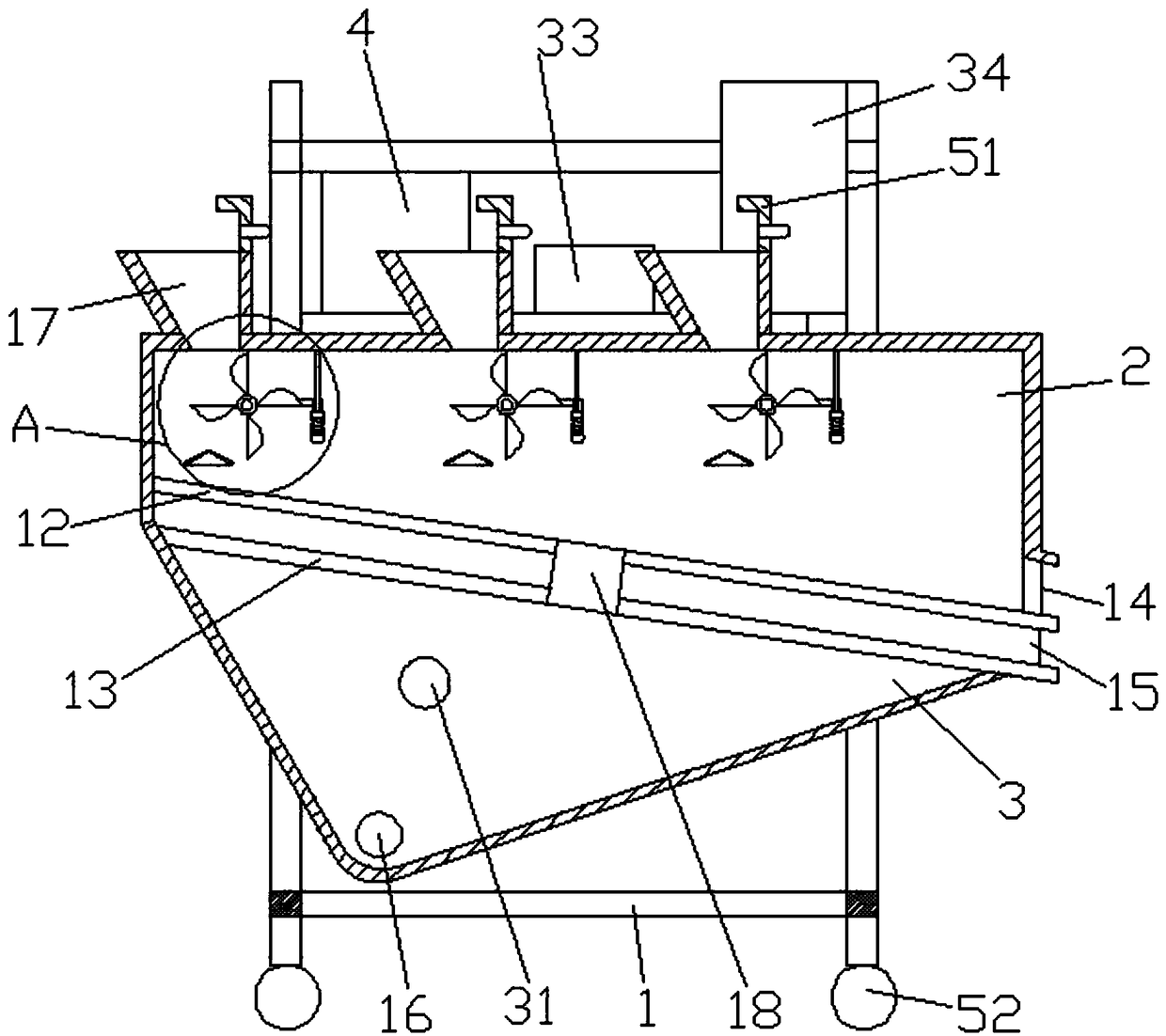

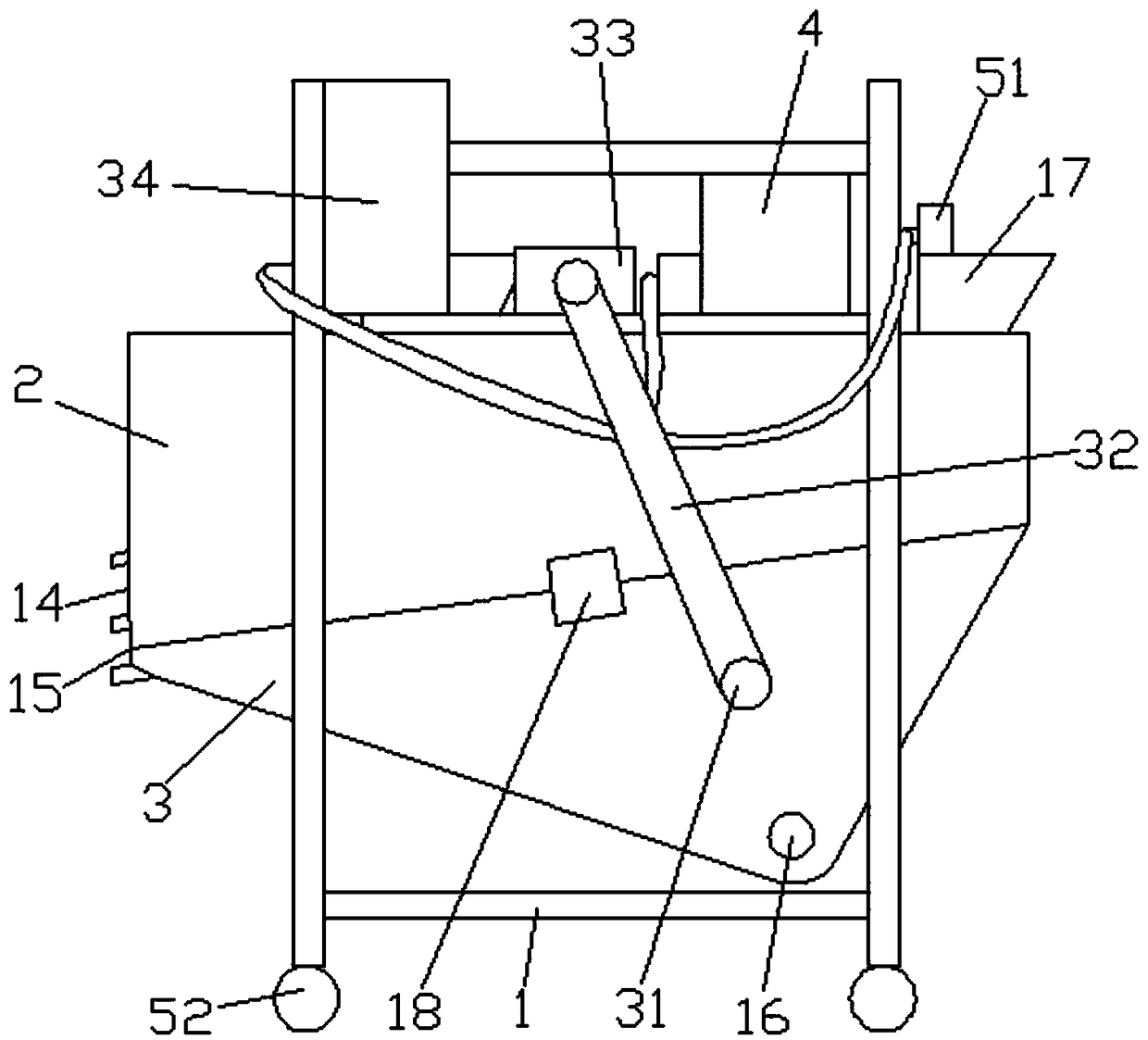

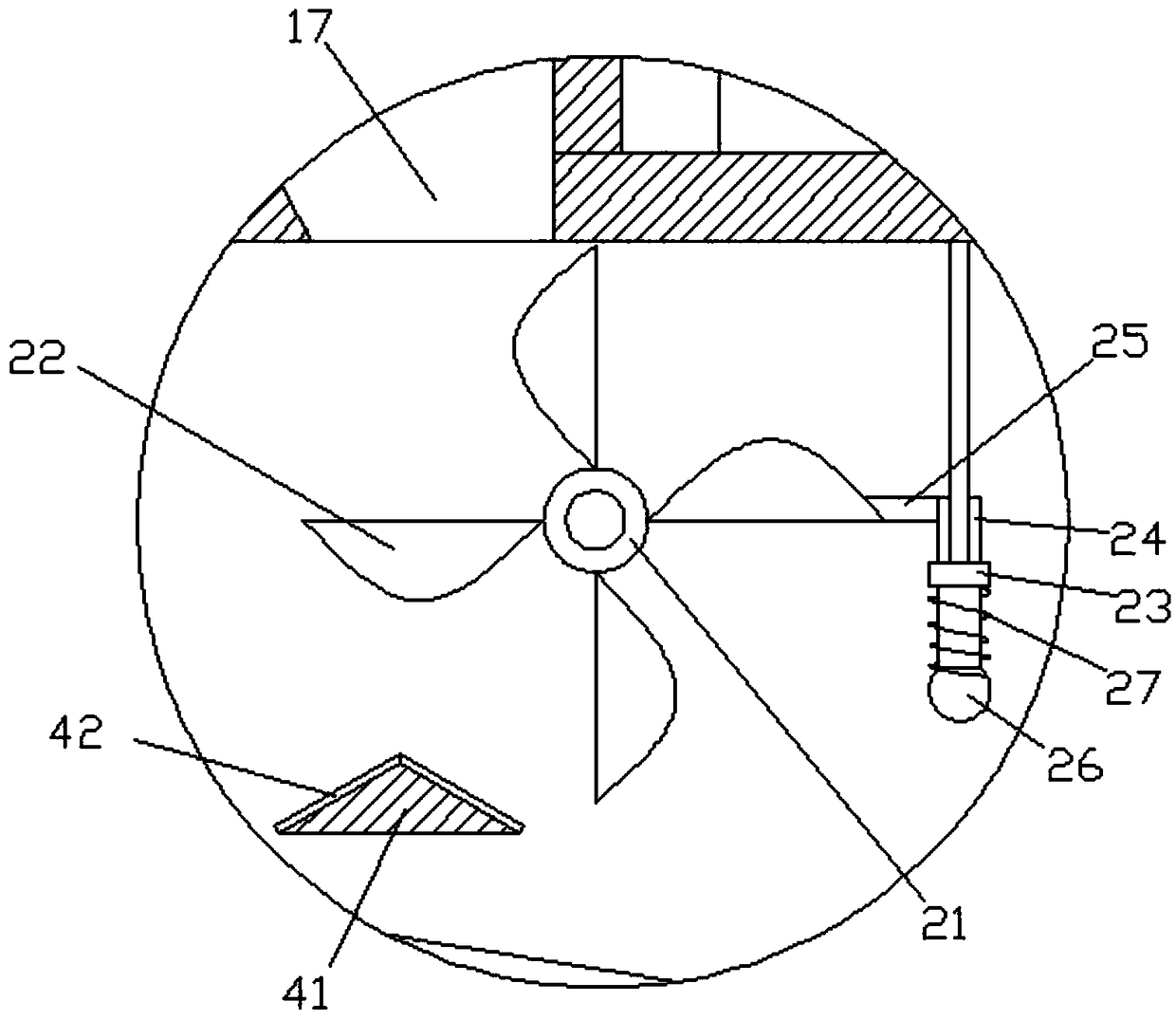

[0024] to combine figure 1 , figure 2 , image 3 Shown; a cylinder head casting production sand treatment regeneration control material screening device, including device bracket 1, upper box 2, lower box 3, control electric box 4, lower box 3 is fixedly installed on the device bracket 1, the upper The box body 2 is installed on the upper part of the lower box body 3 and the lower box body 3 is covered to form a closed box body. The first vibrating screen 12 and the second vibrating screen 13 are installed obliquely between the upper box body 2 and the lower box body 3. The bottom of the first vibrating screen 12 is provided with a large miscellaneous outlet 14 corresponding to the upper box 2, the bottom between the first vibrating screen 12 and the second vibrating screen 13 is provided with a discharge port 15, and the bottom of the lower box 3 There is a small miscellaneous outlet 16, and the upper box body 2 is provided with a feed inlet 17 corresponding to the upper p...

Embodiment 2

[0032] to combine figure 1 , figure 2 , image 3 Shown; a cylinder head casting production sand treatment regeneration control material screening device, including device bracket 1, upper box 2, lower box 3, control electric box 4, lower box 3 is fixedly installed on the device bracket 1, the upper The box body 2 is installed on the upper part of the lower box body 3 and the lower box body 3 is covered to form a closed box body. The first vibrating screen 12 and the second vibrating screen 13 are installed obliquely between the upper box body 2 and the lower box body 3. The bottom of the first vibrating screen 12 is provided with a large miscellaneous outlet 14 corresponding to the upper box 2, the bottom between the first vibrating screen 12 and the second vibrating screen 13 is provided with a discharge port 15, and the bottom of the lower box 3 There is a small miscellaneous outlet 16, and the upper box body 2 is provided with a feed inlet 17 corresponding to the upper p...

Embodiment 3

[0042] Such as figure 1 As shown, on the basis of Example 1, multiple groups of feeding ports can be arranged on the upper part of the upper box body, and wheel rollers and receiving troughs are respectively installed inside the upper box body at the place of each group of feeding ports, and the vibrating screen is evenly used to increase the Great work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com