Self-installation type offshore booster station structure and installation method thereof

An offshore step-up station and installation method technology, applied in the field of marine engineering, can solve problems such as the inability of large cranes to operate, and achieve the effects of avoiding high dependence, reducing the probability of risk, and reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

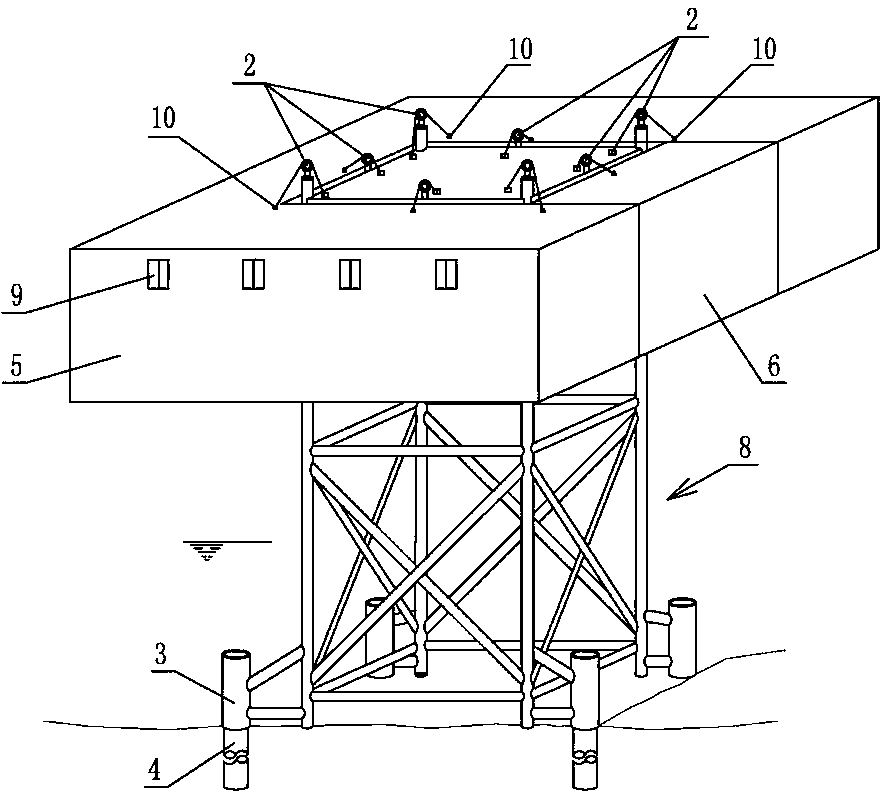

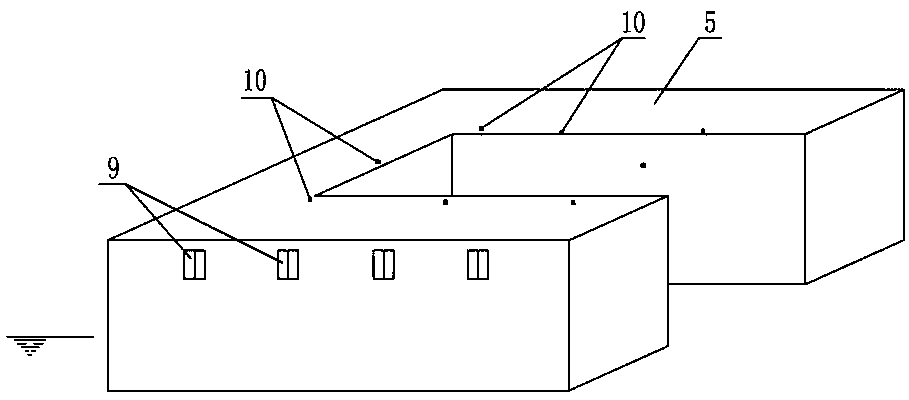

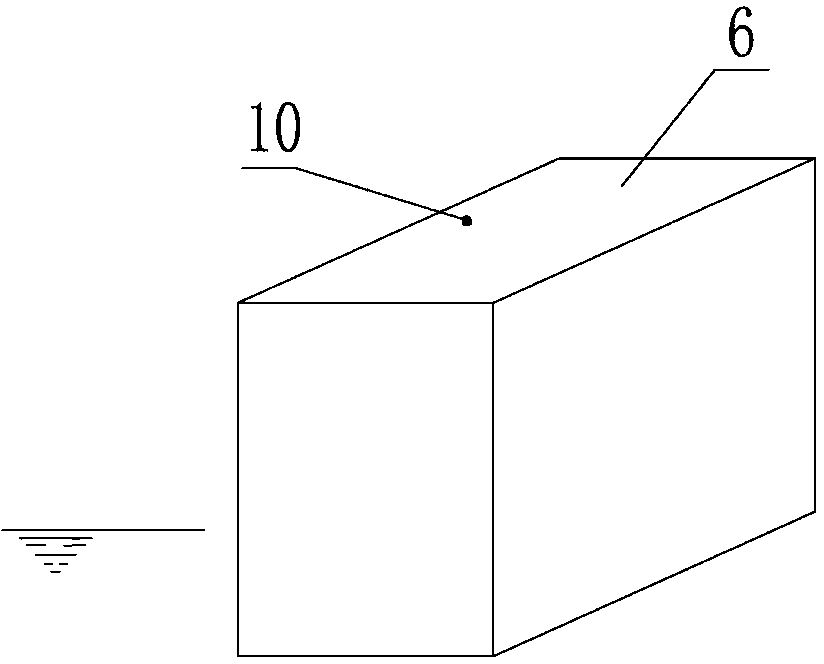

[0026] Such as figure 1 As shown, this embodiment includes four regularly arranged steel piles 4 (the number is determined according to the stress situation), the jacket 8 fixedly installed above the steel piles 4, and the upper equipment group of the booster station installed on the jacket 8 piece. The four steel piles 4 are arranged vertically (or slightly inclined), and their lower ends go deep into the bearing layer below the seabed, and the projection of each steel pile 4 on the horizontal plane is four vertices of a square. The bottom end of the jacket 8 is fixedly connected to the steel pile 4 through the pile casing 3, and the top end is provided with a hoisting mechanism 2, which is used to lift the upper equipment block of the booster station to the set position, and then install it on the jacket 8 (in this example, buckles are reserved on the upper part of the jacket to connect the upper equipment block). The upper equipment block of the booster station is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com