Automatic glazing method for ceramic bowl blank

A technology for ceramic blanks and ceramic bowls, which is applied in the field of automatic glazing on the surface of daily-use ceramic bowl blanks. It can solve the problems of daily-use porcelain industry, high equipment investment, and difficulty in recycling, etc., to achieve uniform glazing, high production efficiency, and The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

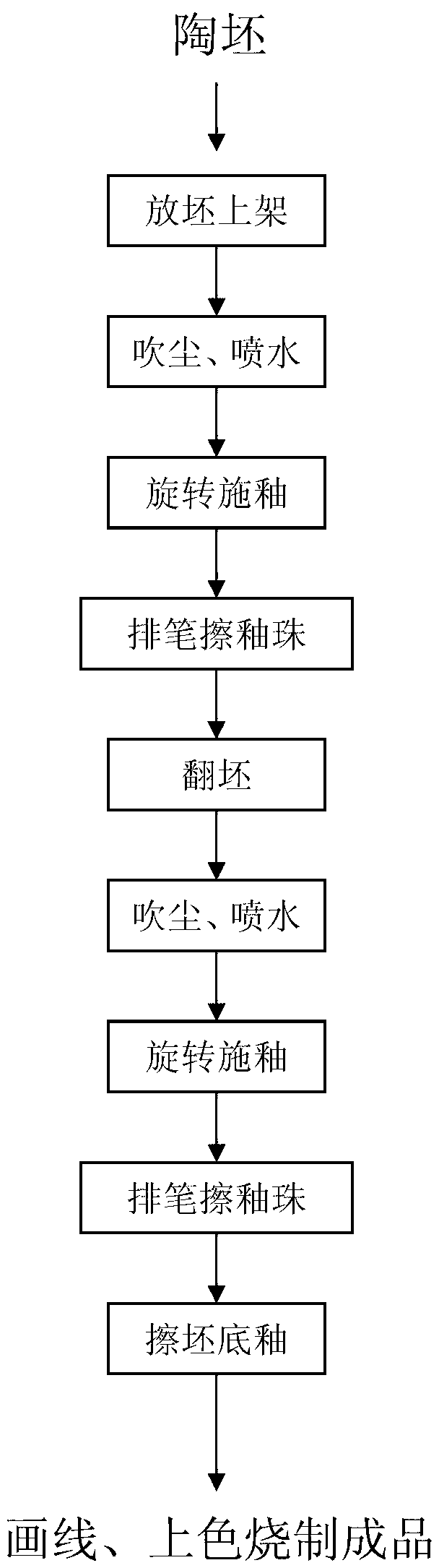

[0024] Such as figure 1 As shown, the daily-use ceramic bowl is placed on the support after being pressed and trimmed, and then the moving support is rotated to drive the blank to rotate rapidly, and then the glaze is poured on the blank to control the flow of the glaze. The centrifugal force is used to spread the glaze slurry evenly over the entire surface to complete the glazing, and the excess glaze slurry is thrown out from the edge of the blank and collected for recycling.

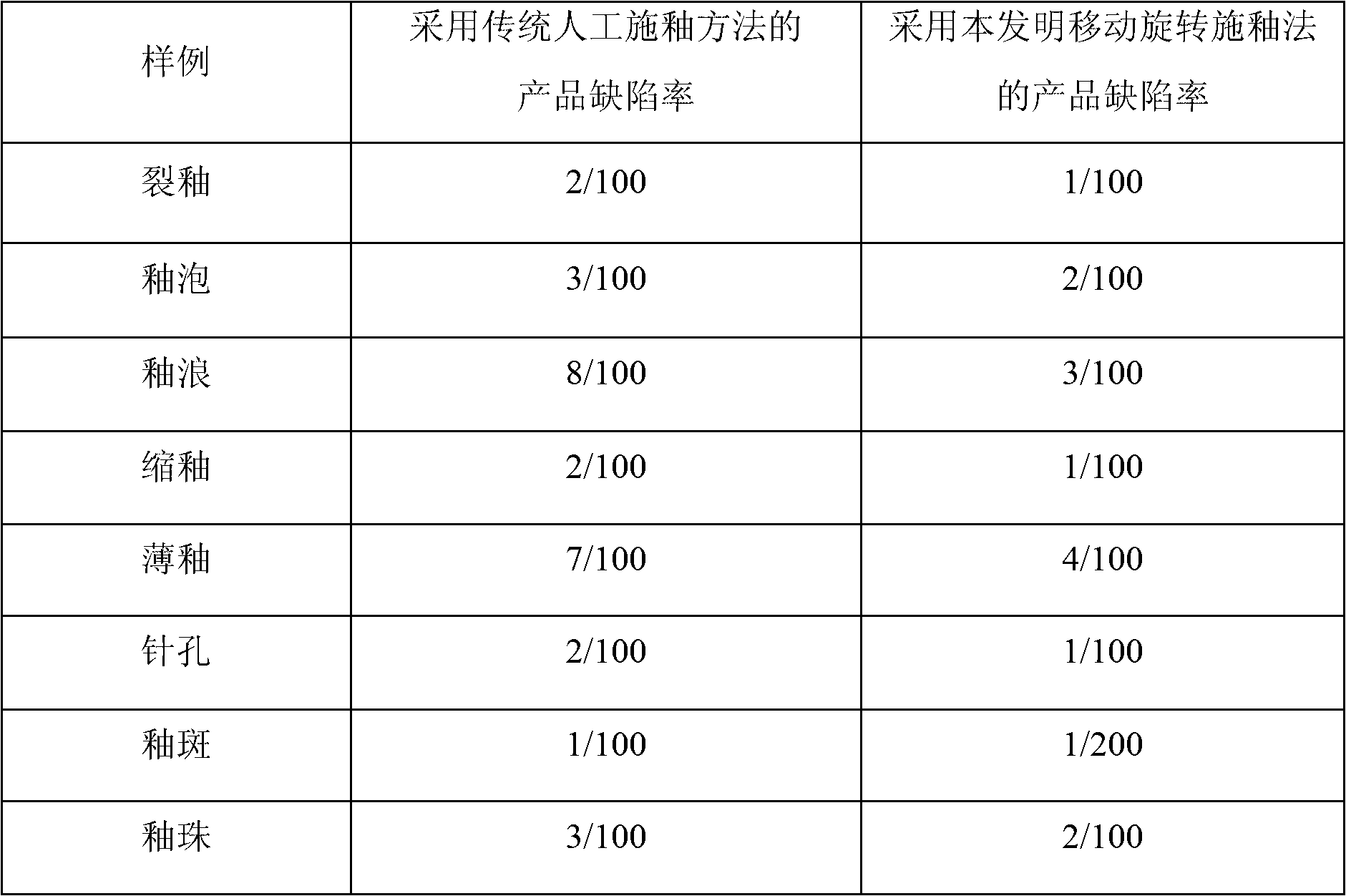

[0025] Take the daily-used pressed bowl blank, use transparent glaze slurry, apply glaze according to the above-mentioned technical scheme, and get the embodiment, the glaze effect is compared with the traditional method as follows:

[0026] Table 1 Glazing results of blank glaze

[0027]

[0028] As can be seen from Table 1, using the traditional manual glazing method, the qualified rate of the product depends to a large extent on the workman's technology and operating degree, and the degree of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com