Automatic control system of sludge deep dewatering overall process and treatment method

An automatic control system, deep dewatering technology, applied in dewatering/drying/concentrating sludge treatment, comprehensive factory control, comprehensive factory control, etc. cost, stable and continuous optimized operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

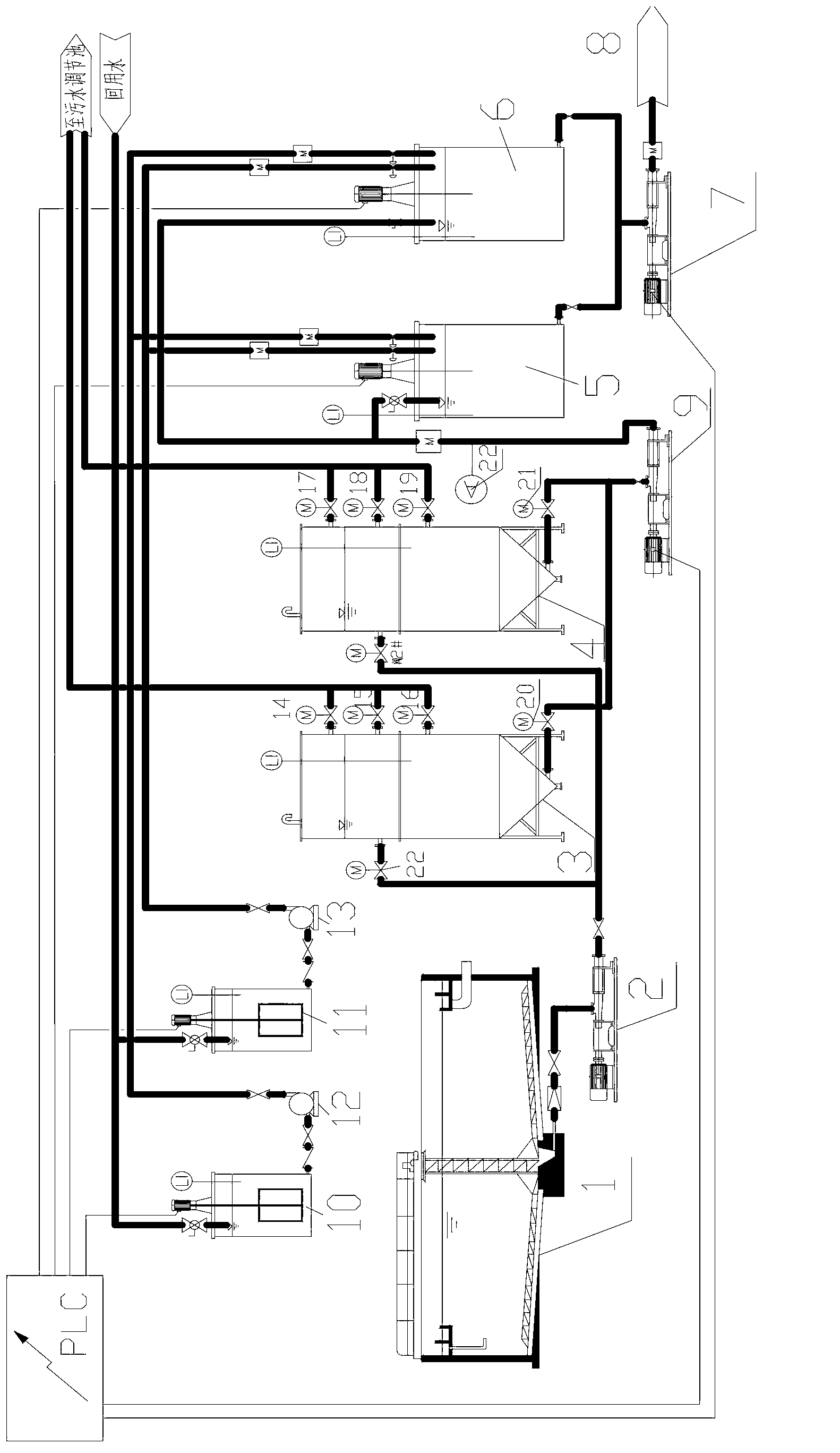

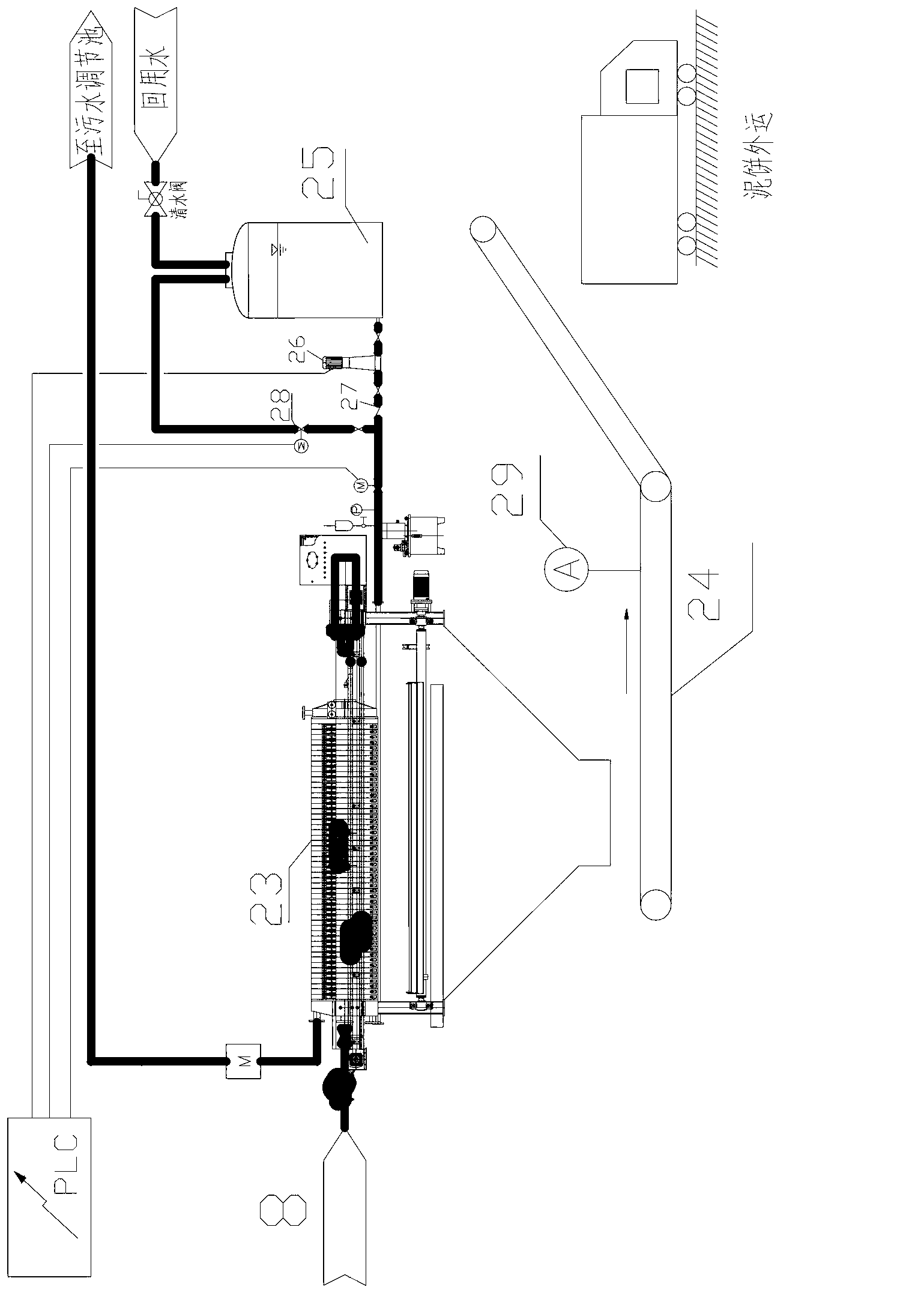

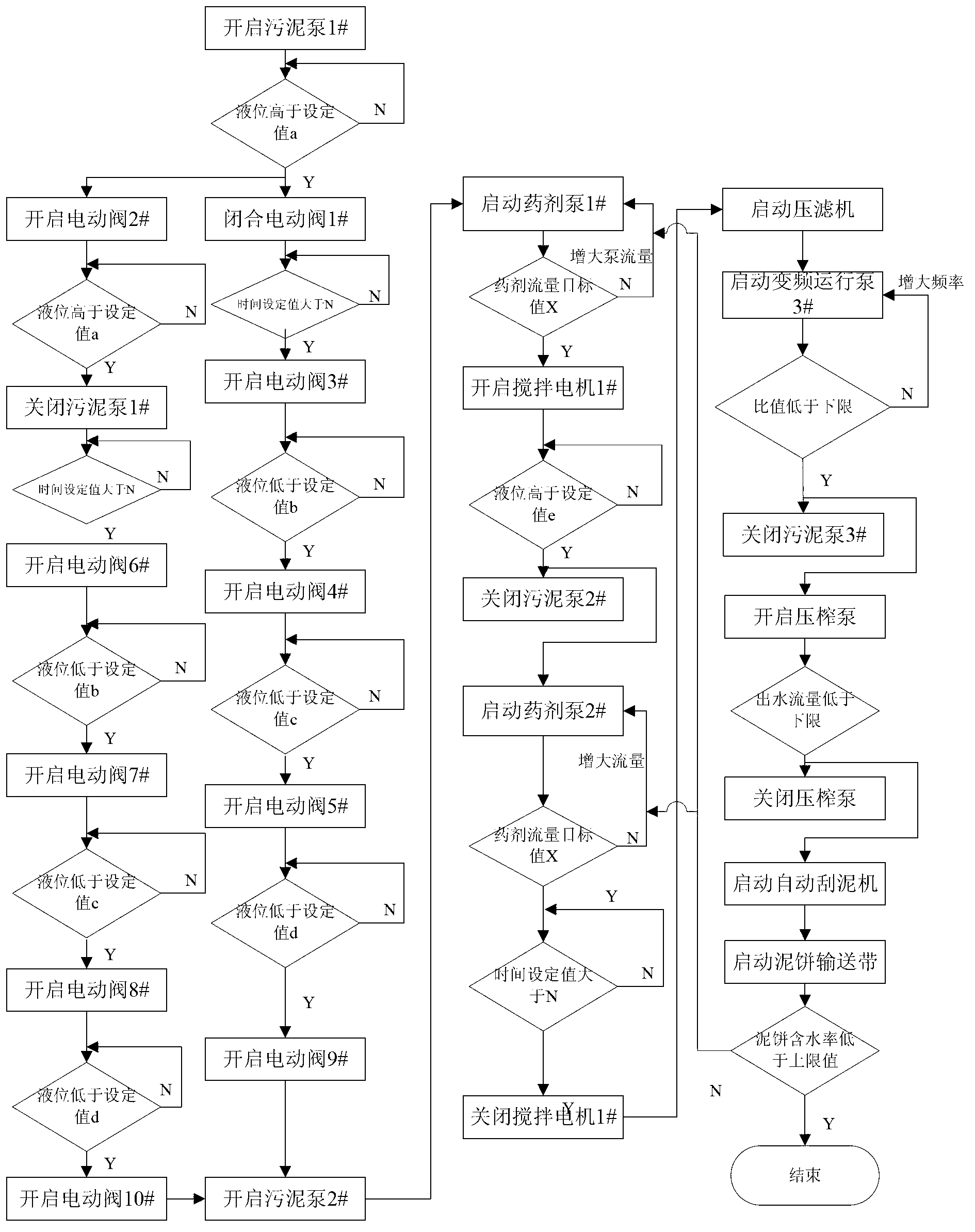

[0030] The sludge deep dehydration treatment process of the present invention is as Figure 1.a , Figure 1.b As shown, it includes sludge pre-thickening part, sludge conditioning part, sludge deep dehydration part and mud cake conveying part. Process route description: The sludge from the secondary settling tank 1 is transported by the first sludge pump 2 into the gravity concentration tanks 3 and 4, and after 2-7 hours of precipitation in the gravity concentration tank, the sludge and water are separated. The actual liquid level detected by the liquid level gauge is compared with the set value to control the opening and closing of the water outlet electric valves 14~16, 17~19. The concentrated sludge is transported into the sludge conditioning tanks 5 and 6 by the second sludge pump 9, and the electric valves 20 and 21 control the discharge and transportation of the concentrated sludge, and the sludge pipes entering the conditioning tanks are installed with sludge Density m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com