Method for treating wastewater

A technology for treating waste water and waste water, applied in water softening, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of serious membrane pollution, increase the load of evaporation treatment, etc., simplify the operation steps and increase the concentration multiple , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

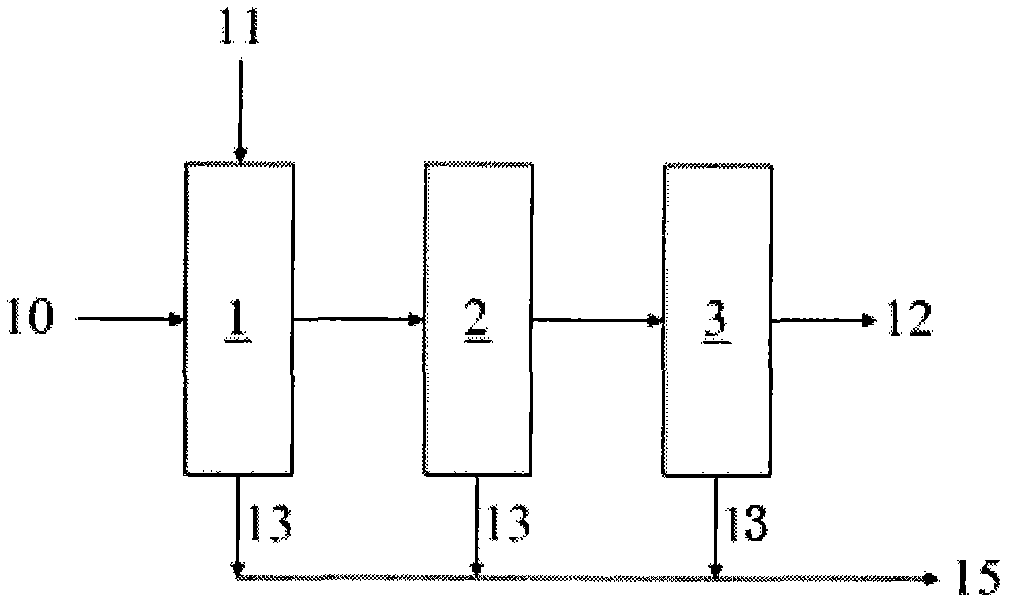

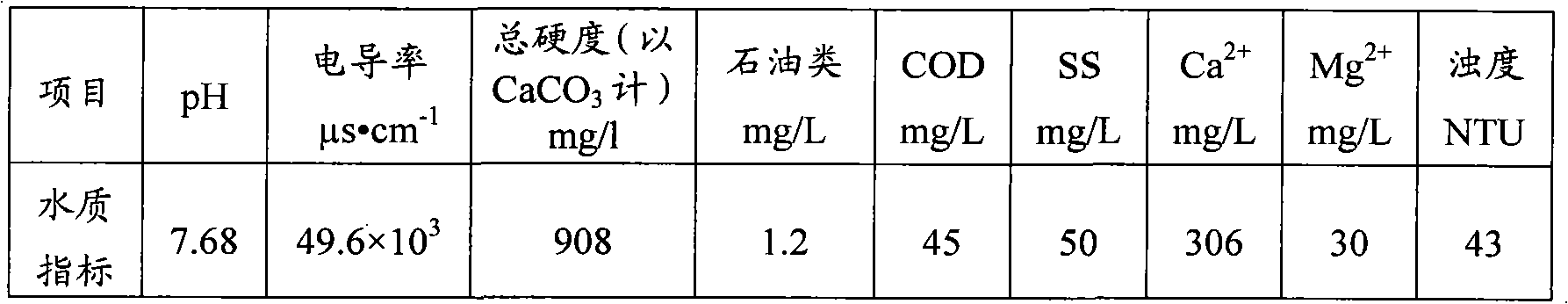

[0027] The lye incineration waste water (its composition is shown in Table 1) in the ethylene production is discharged in the hard reaction pool 1, and according to the Mg in the waste water 2+ Concentration and Ca 2+ Concentration added NaOH and Na 2 CO 3 , where the amount of NaOH added is Mg 2+ 2 times the amount, Na 2 CO 3 The amount added is Ca 2+ 1 times the amount to precipitate Mg in wastewater 2+ and Ca 2+, while making the pH of the wastewater reach 9. After reacting in the hard removal reaction tank 1 for 30 minutes, the waste water is discharged into the filter 2 for filtration. The inlet filter used here is a ceramic membrane filter with a membrane pore size of 0.1 μm, and the SS concentration of the microfiltration water is 0.5 mg / L, the turbidity is 0.1NTU, its specific composition is shown in Table 2, and the slurry 13 with a solid content of 3% is discharged at the same time. Next, the wastewater is discharged into the vacuum membrane distillation dev...

Embodiment 2

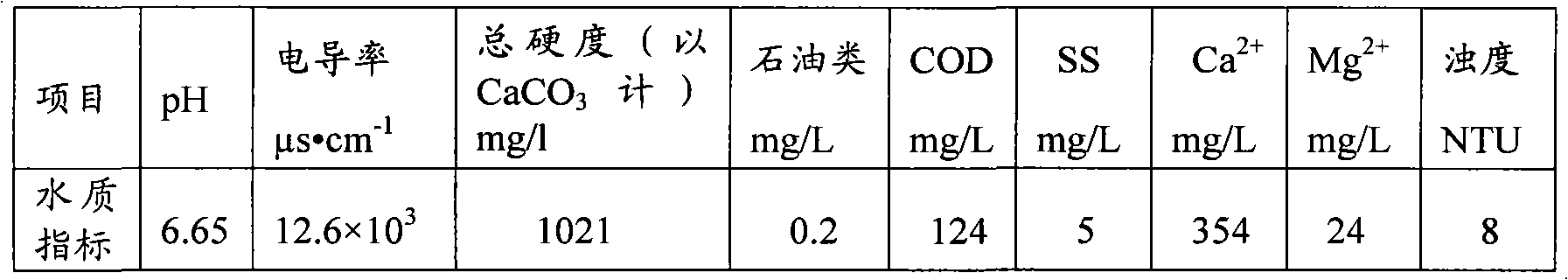

[0033] Discharge the secondary reverse osmosis concentrated wastewater (see Table 3 for its composition) from the refinery sewage reuse unit into the hardening reaction tank 1, and according to the Mg in the wastewater 2+ Concentration and Ca 2+ Concentration added NaOH and Na 2 CO 3 , where the amount of NaOH added is Mg 2+ 2 times the amount, Na 2 CO 3 The amount added is Ca 2+ 1 times the amount to precipitate Mg in wastewater 2+ and Ca 2+ , while making the pH of the wastewater reach 9. After reacting in the hard removal reaction tank 1 for 30 minutes, the waste water is discharged into the filter 2 for filtration. The microfiltration membrane filter used here is a ceramic membrane filter with a membrane pore size of 0.1 μm, and the SS concentration of the microfiltration water The turbidity is 0.3mg / L, the turbidity is 0.1NTU, its specific composition is shown in Table 4, and the slurry 13 with a solid content of 3% is discharged at the same time. Next, the waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com