Micro and nano-grade light calcium carbonate tube-condensation-type double-circulation multi-level carbonation system

A light calcium carbonate, tube condensation technology, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, nanotechnology, etc. The effect of carbonization efficiency, prolonging maintenance period and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

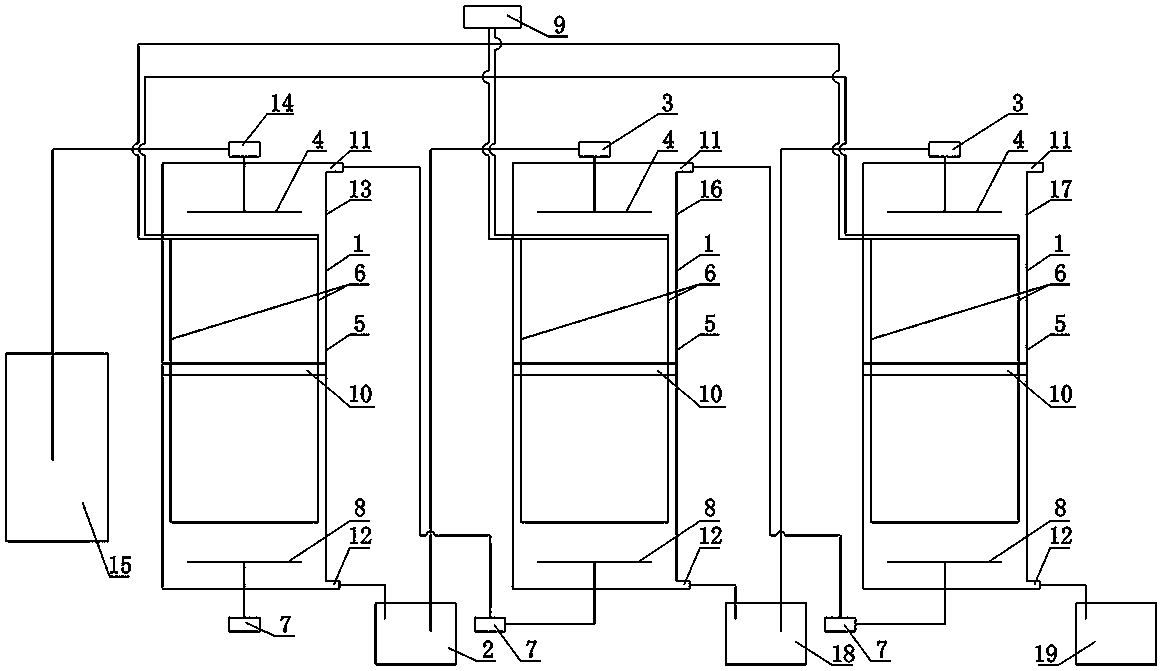

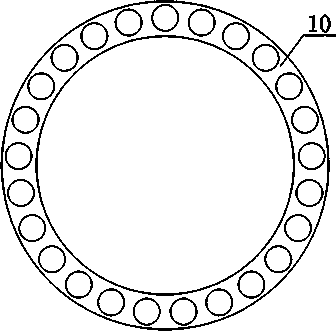

[0013] Such as figure 1 Shown, micro and nanoscale light calcium carbonate column and tube condensing double cycle multistage carbonization system, it comprises at least three carbonization towers 1 connected in series, and be provided with slurry groove 2 between adjacent carbonization towers 1, described The carbonization tower 1 includes a high-pressure pump 3, a spray mist making device 4, a tower body 5, a condensation tube 6, an air compressor 7, a gas separator plate 8, a refrigerator 9, and a liquid and scale removal device 10, and the tower body 5 A tail gas outlet 11 is provided above the tower body 5, a liquid outlet 12 is provided below the tower body 5, a high-pressure pump 3, an air compressor 7 and a refrigerator 9 are all arranged outside the tower body 5, and the condensation tube 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com