Metal mold positioning and fixing device

A technology for fixing devices and molds, which is applied in the field of mold positioning and fixing devices, and can solve problems such as deterioration of molded product quality and multiple defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

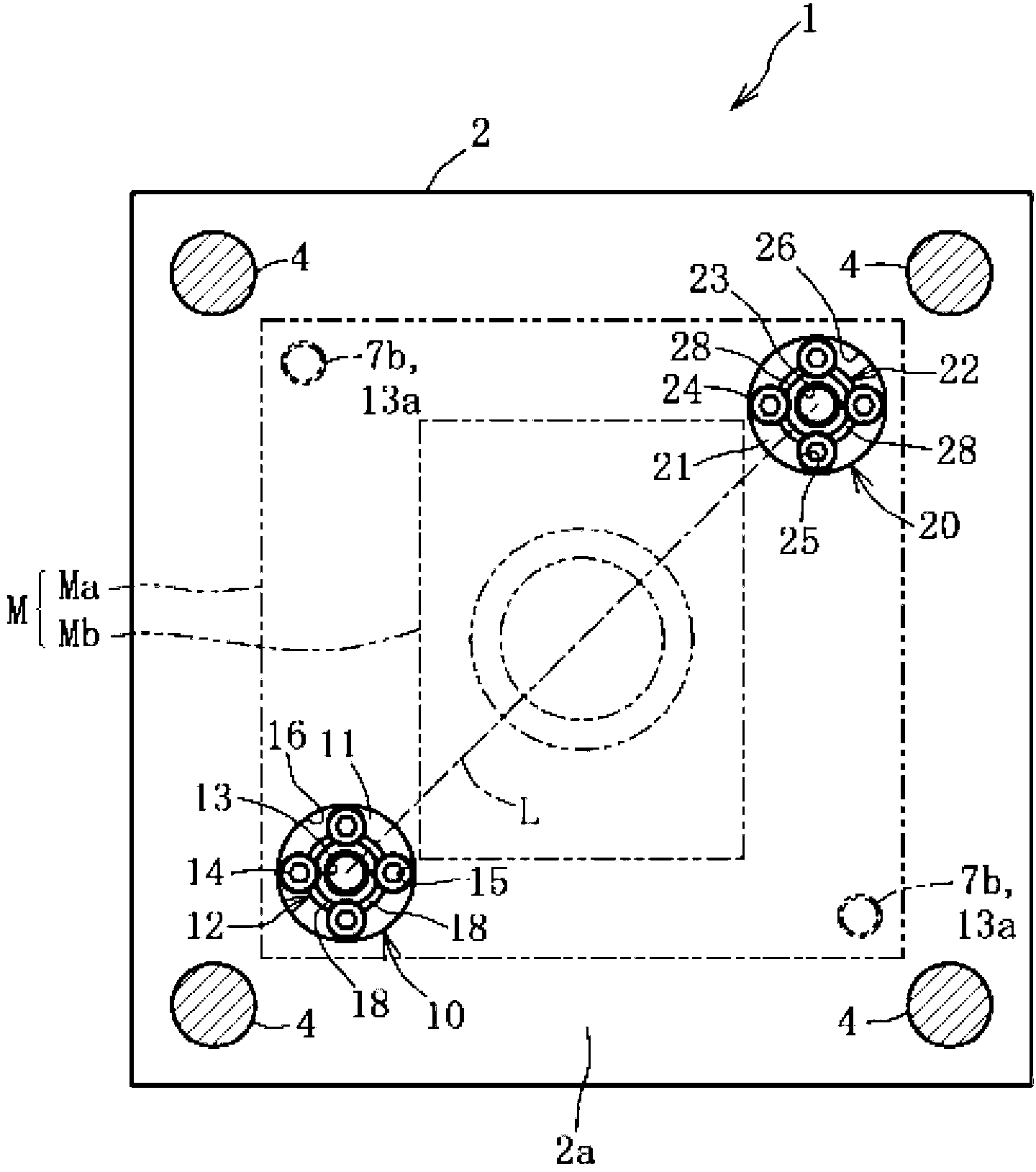

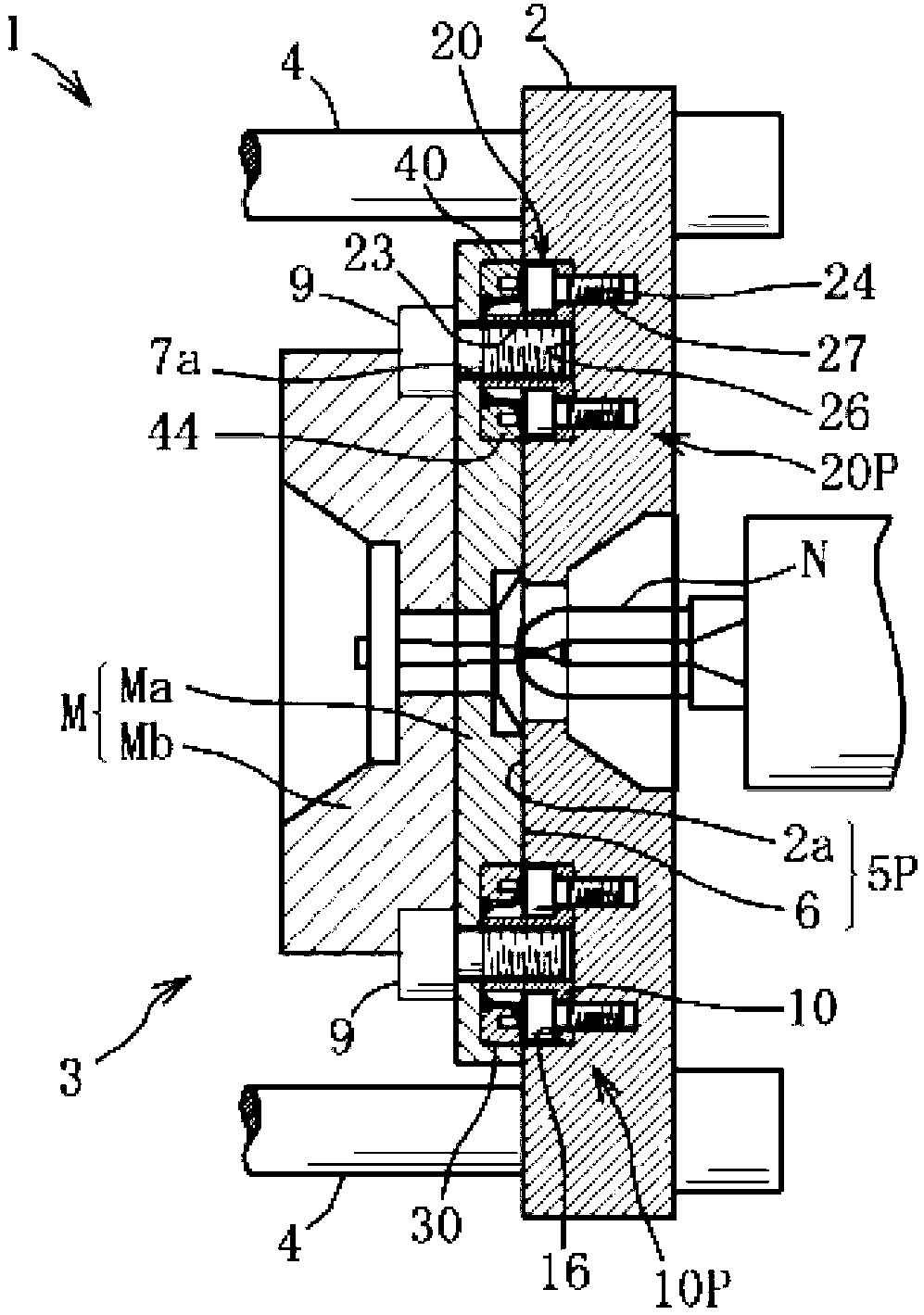

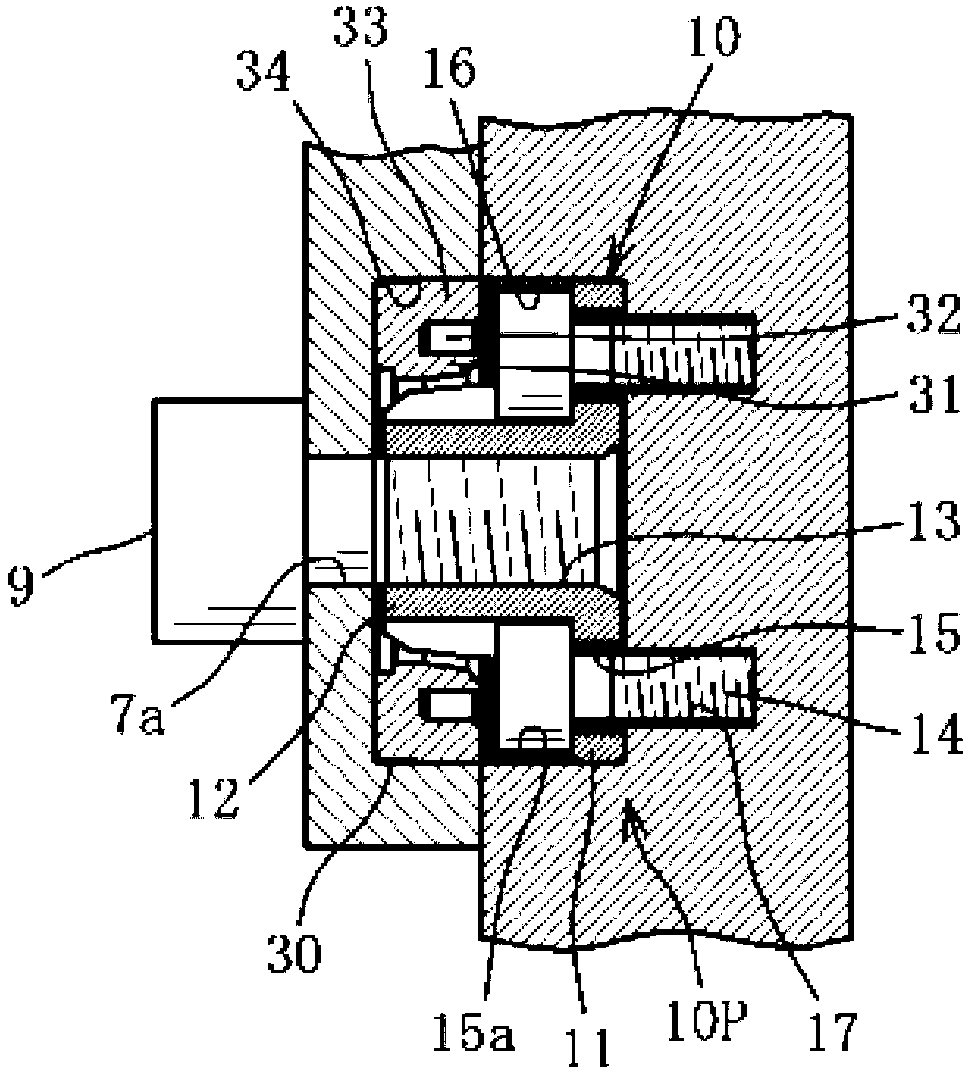

[0046] This embodiment is an example of the mold positioning and fixing device 3 suitable for positioning and fixing the fixed mold M on the disk surface 2 a of the fixed disk 2 of the injection molding machine 1 according to the present invention.

[0047] Such as figure 1 , figure 2 As shown, the fixed side mold M is installed on the disk surface 2a of the fixed disk 2 of the injection molding machine 1; the movable side mold is installed on the disk surface of the movable disk, which is omitted in the figure. The fixed-side mold M (hereinafter referred to as mold M) is provided with: a mold substrate Ma fixed on the disk surface 2a; and a mold body Mb integrally fixed on the mold substrate Ma. Guide rods 4 for guiding the movable platen are respectively inserted and fixed to four corners of the fixed platen 2 of the injection molding machine 1 . The injection nozzle N can protrude into the central hole of the fixed plate 2, and the melted synthetic resin is injected from...

Embodiment 2

[0079] Such as Figure 7 As shown, the mold positioning and fixing device 3A is basically the same as the mold positioning and fixing device 3 of Embodiment 1. Here, the same symbols as the components of Embodiment 1 are marked with the same symbols and descriptions are omitted. The only difference is that it is different from the clip The structure related to the tightening bolt 9A will be described below only with respect to this different structure.

[0080] Such as Figure 7 As shown, bolt holes 13A, 23A are used to replace the bolt holes of the tapered engaging protrusions 12A, 22A of the first reference member 10A and the second reference member 20A, and the fixing plate 2 corresponds to the bolt insertion holes 13A. , 23A is formed with a pair of bolt holes 13b, 23b. The clamping bolt 9A is first inserted through the bolt insertion hole 7a, then respectively inserted through the bolt insertion holes 13A, 23A, and then the clamping bolt 9A is screwed to the bolt holes ...

Embodiment 3

[0082] Figure 8 The mold positioning and fixing device 3B shown is basically the same as the mold positioning and fixing device 3 of Embodiment 1. Here, the same symbols as the components of Embodiment 1 are marked with the same symbols and descriptions are omitted. The only difference is that it is different from the clip The structure related to the tightening bolt 9A will be described below with respect to this different structure.

[0083] Such as Figure 8 , Figure 9 As shown, in the vicinity of the first reference member 10B, the mold M is fixed on the fixed disk 2 by screwing the clamping bolt 9B passing through the bolt insertion hole 7c of the mold M and the bolt hole 2B of the fixed disk 2. . Similarly, the die M is fixed to the fixed platen 2 by clamping bolts 9B in the vicinity of the second reference member 20B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com