An integrated, washable and reusable three-dimensional (3d) multifunctional knitted fabric structure and method to produce the same

A knitted fabric, multi-functional technology, applied in the direction of fabric, knitting, weft knitting, etc., can solve the problem of not involving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

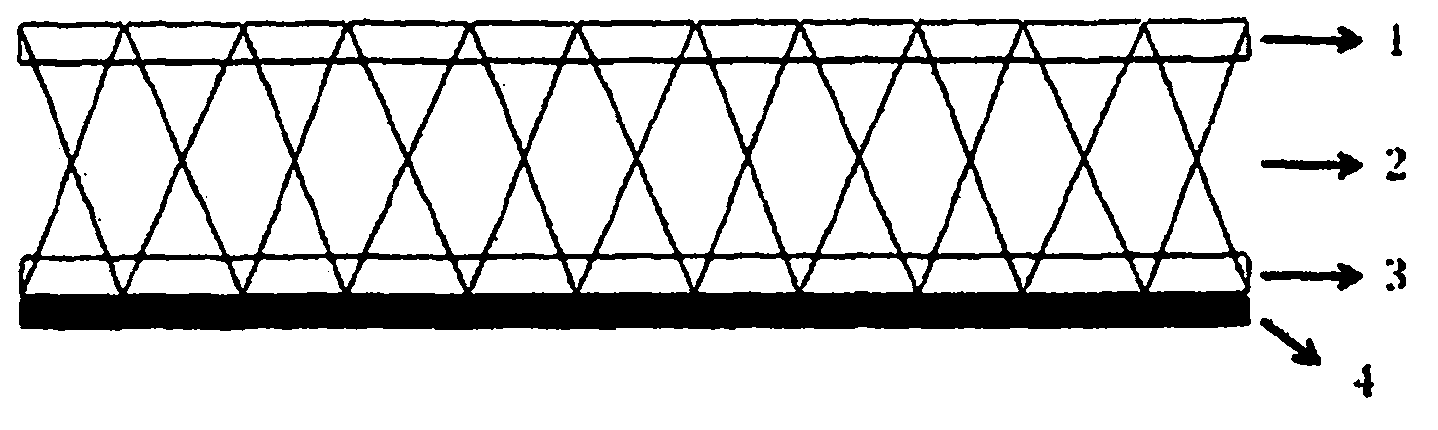

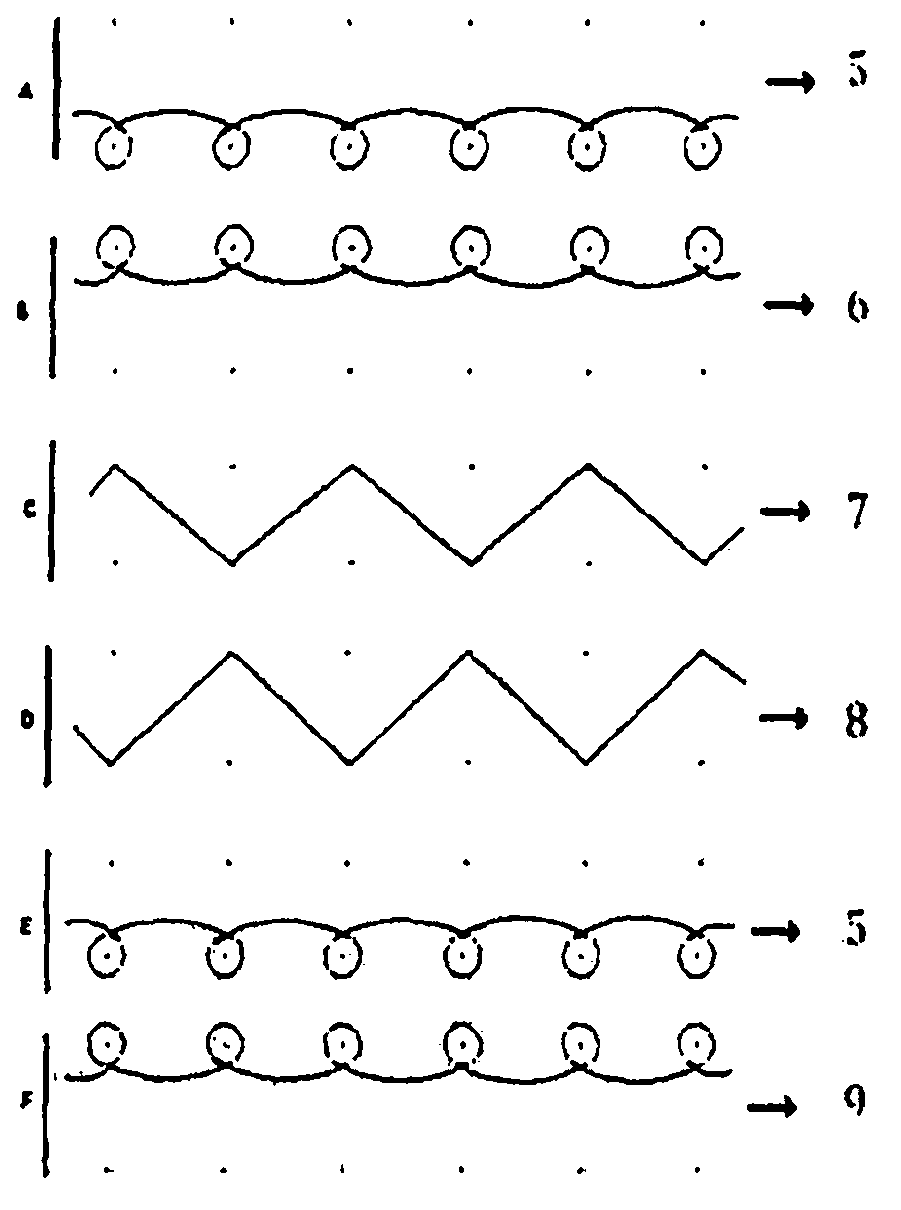

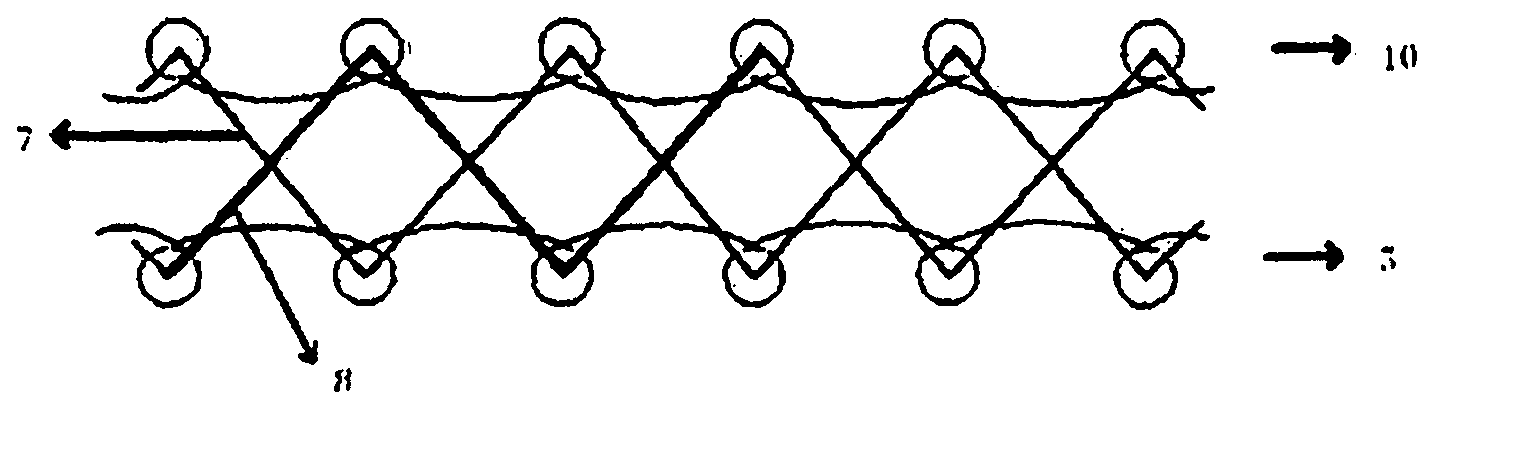

[0034] The present invention relates to a three-dimensional (3D) multifunctional knitted structure comprising an inner knitted layer, an outer knitted layer, connecting cross threads and a coated / laminated film on the outer layer. 3D structures (except coated / laminated films) are used on flat or circular knitting machines on the dial and cylinder (when knitting circular) and on the front needle bed and Special stitch combinations performed on the rear needle bed (in the case of plain weaving technology) are produced integrally and in a single step. This combination of special coils enables the fabrication of two separate layers (inner and outer layers) connected by monofilament threads oriented in the thickness direction, thus giving the structure the three-dimensionality required for the application. The functionality given to the structure is provided by the orientation of the fibers in the structure itself and by the use of functional fiber yarns with specific characteristi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com