Full-automatic battery cell winding device

A cell roll, fully automatic technology, applied in secondary battery manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of increasing process complexity, adverse cell quality, and high cost, and achieve the production process. Simple and convenient, shorten working time, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through embodiments in conjunction with the accompanying drawings.

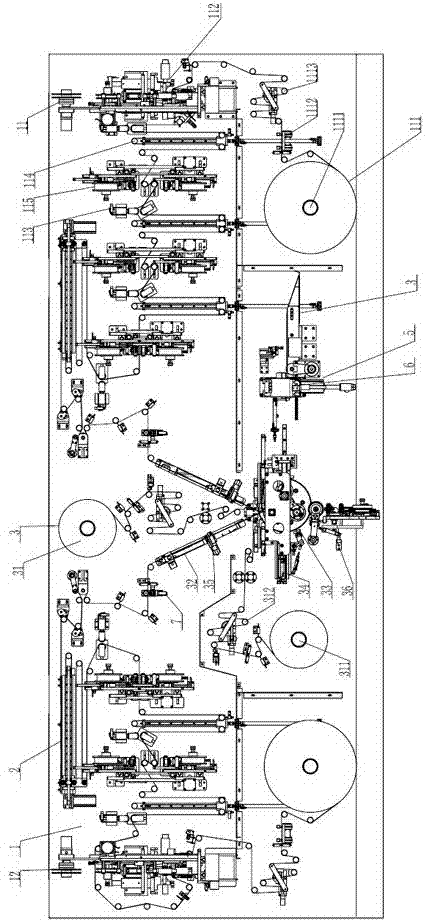

[0023] refer to figure 1 , in a specific embodiment, the fully automatic cell winding device may include a sheet making part 1, a winding part 3 and a blanking part 4, and the sheet making part 1 includes a positive electrode sheet making unit 11 and a negative electrode sheet making unit 12 The positive electrode sheet making unit 11 and the negative electrode sheet making unit 12 respectively include an unwinding mechanism 111, a lug welding mechanism 112, a traction mechanism 113, a tension control mechanism 114, and a gluing mechanism 115, and the winding part 3 includes a diaphragm input mechanism 31, an input A sheet mechanism 32 , a winding mechanism 33 , a diaphragm cutting mechanism 34 , a pole piece cutting mechanism 35 and a termination tape mechanism 36 . In addition to the above parts, the fully automatic cell winding device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com