Micro-motion platform for improving resolution of linear motor based on flexible inclined beam

A technology of micro-motion platform and linear motor, which is applied in the direction of workbench, instrument parts, instruments, etc., can solve the problem of small output force of linear motor, and achieve the effect of avoiding nonlinearity, compact structure and avoiding assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings.

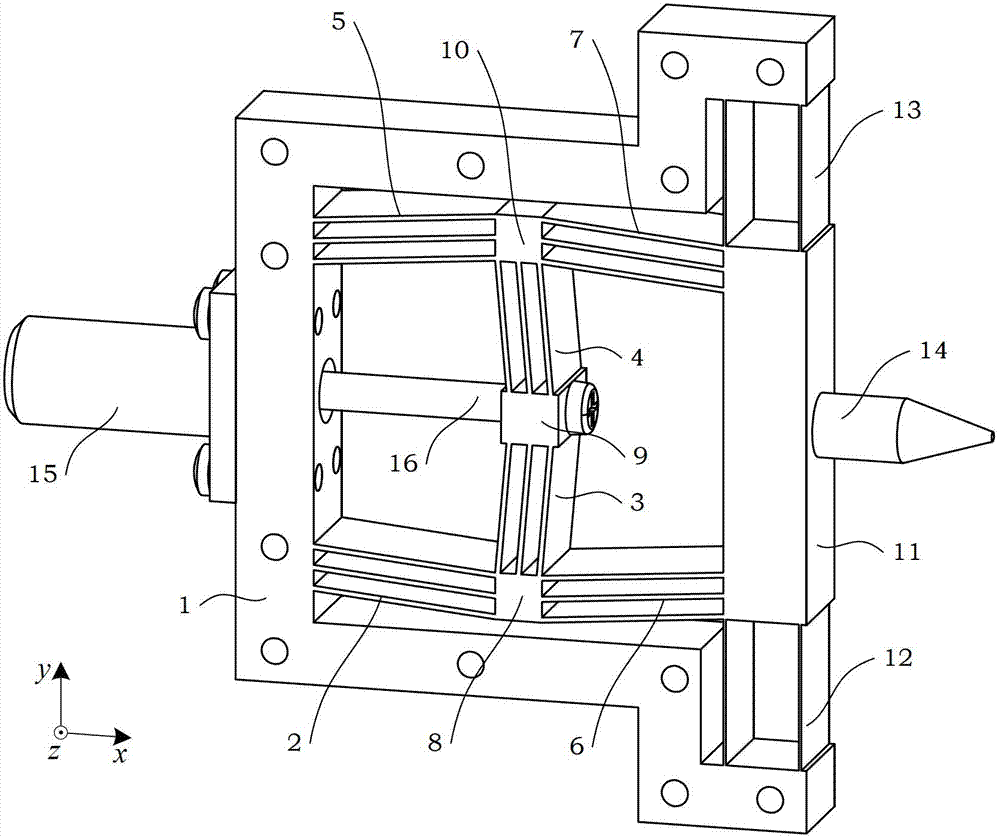

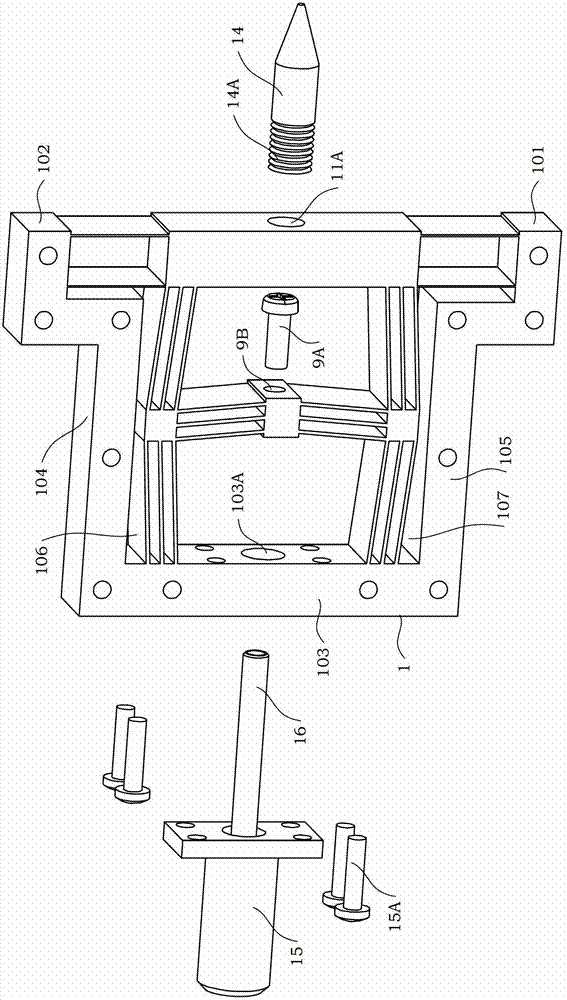

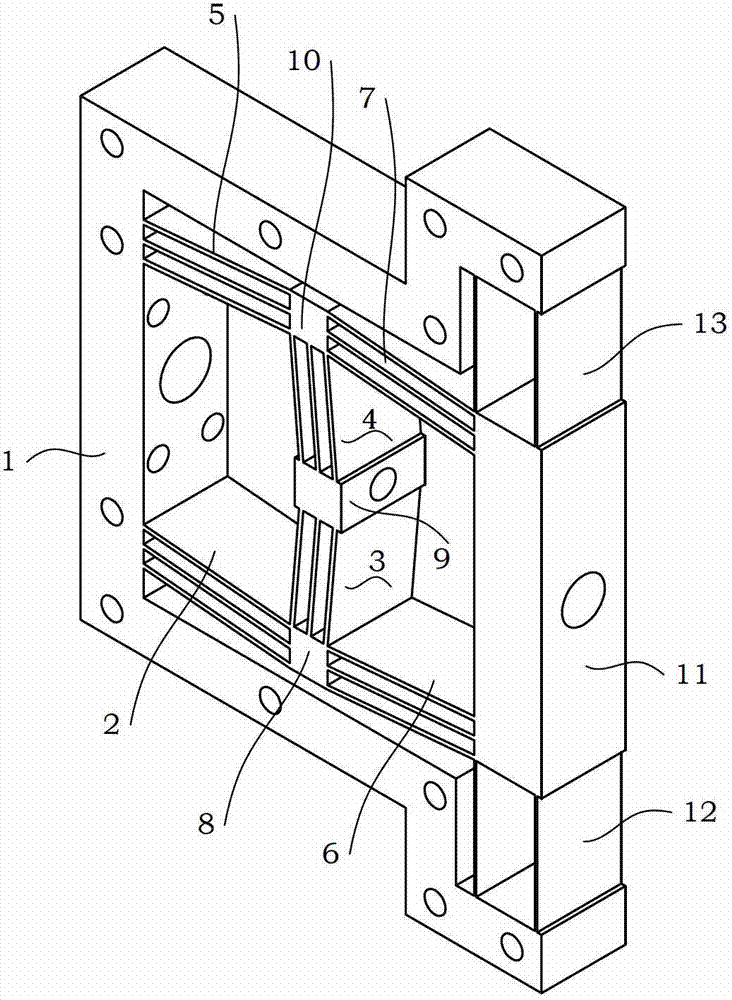

[0039] See figure 1 , Figure 1A As shown, the present invention is a micro-motion platform for improving the resolution of a linear motor based on a flexible inclined beam. The micro-motion platform is an integrated processing structure, and the micro-motion platform is provided with:

[0040] A base 1;

[0041] Six inclined beam assemblies (first inclined beam assembly 2, second inclined beam assembly 3, third inclined beam assembly 4, fourth inclined beam assembly 5, fifth inclined beam assembly 6, and sixth inclined beam assembly 7);

[0042] Two transition plates (the first transition plate 8, the second transition plate 10);

[0043] Two guide beam components (first guide beam component 12, second guide beam component 13);

[0044] One input board 9, one output board 11, and one output rod 14;

[0045] A first guide beam assembly 12, an output plate 11 and a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com