Substrate containing alignment layer and manufacture method thereof and display device thereof

A manufacturing method and technology of alignment layer, which are applied in the directions of instruments, nonlinear optics, optics, etc., can solve the problems affecting the adhesion degree of the frame sealant 14 and the substrate, display defects, and inability to realize the effect of narrow frame design, and achieve the realization of the design effect. effect, effect of reducing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0030] An embodiment of the present invention provides a method for manufacturing a substrate including an alignment layer, the method comprising the following steps:

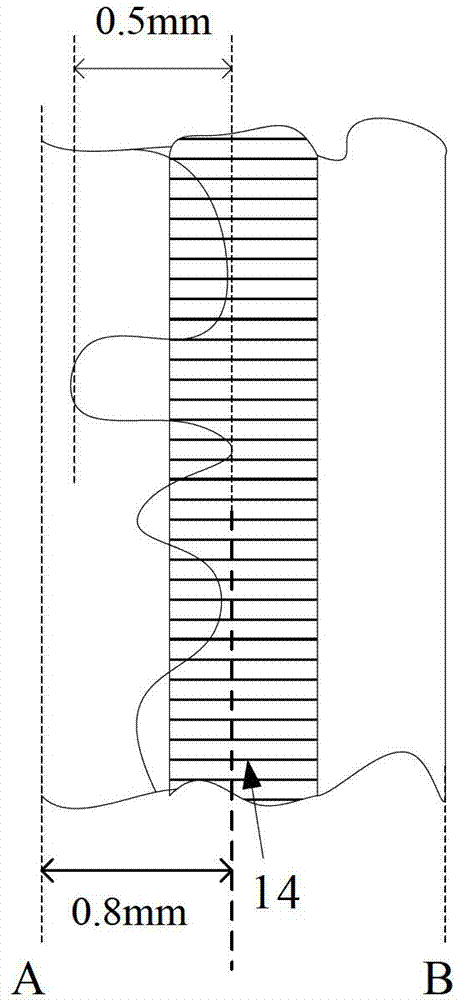

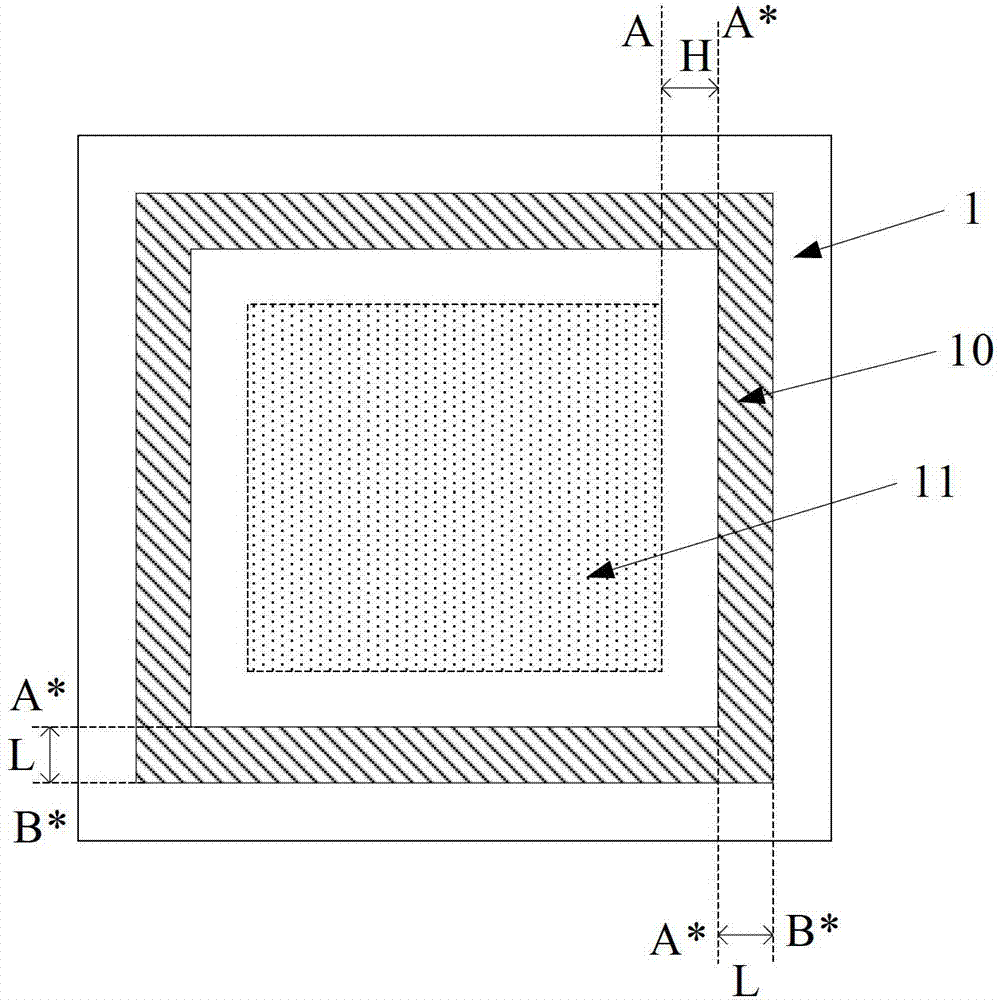

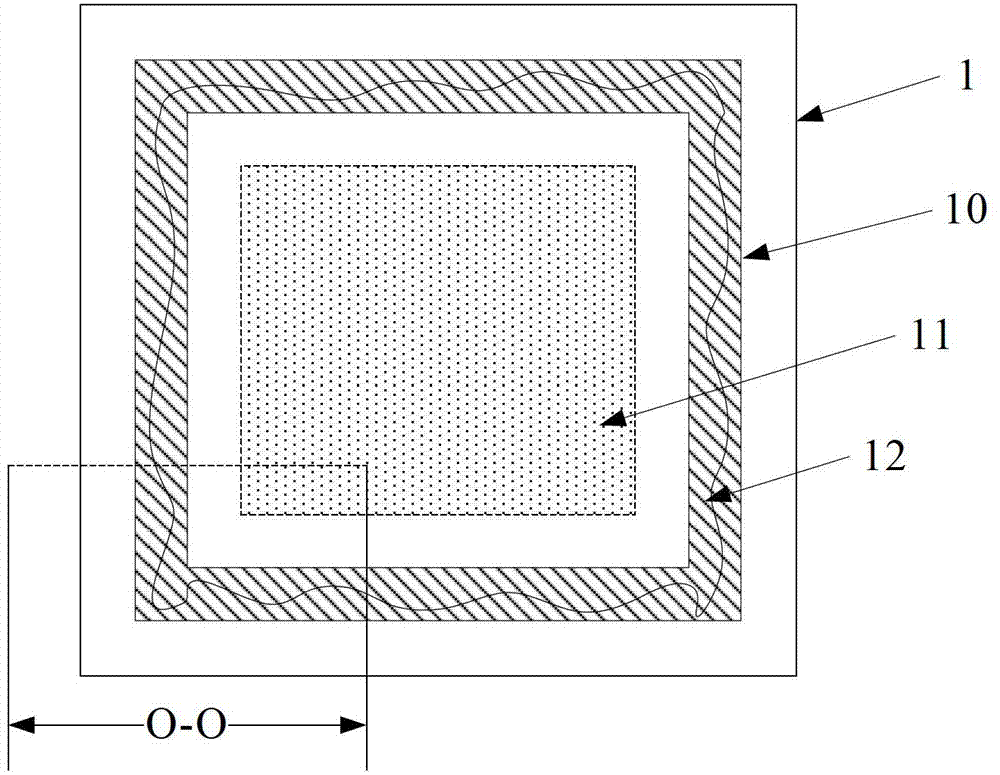

[0031] S1, such as figure 2 As shown, a photosensitive film is fabricated on the substrate 1, and a frame-shaped photosensitive pattern 10 is formed on the periphery of the display area of the substrate through a patterning process; wherein, the inner edge A of the frame-shaped photosensitive pattern 10 * and outer edge B * , are all parallel to the corresponding edge A of the display area 11 .

[0032] Wherein, the material of the photosensitive pattern is a photosensitive resin material. Exemp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com