Method and apparatus for testing viscous oil viscosity on well boring coring site

A field testing and heavy oil viscosity technology, applied in the field of drilling and coring field testing of heavy oil viscosity, can solve the problems of inability to reflect the actual situation of the oil reservoir, large loss of light components, inaccurate test data, etc. The effect of less error, less loss and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

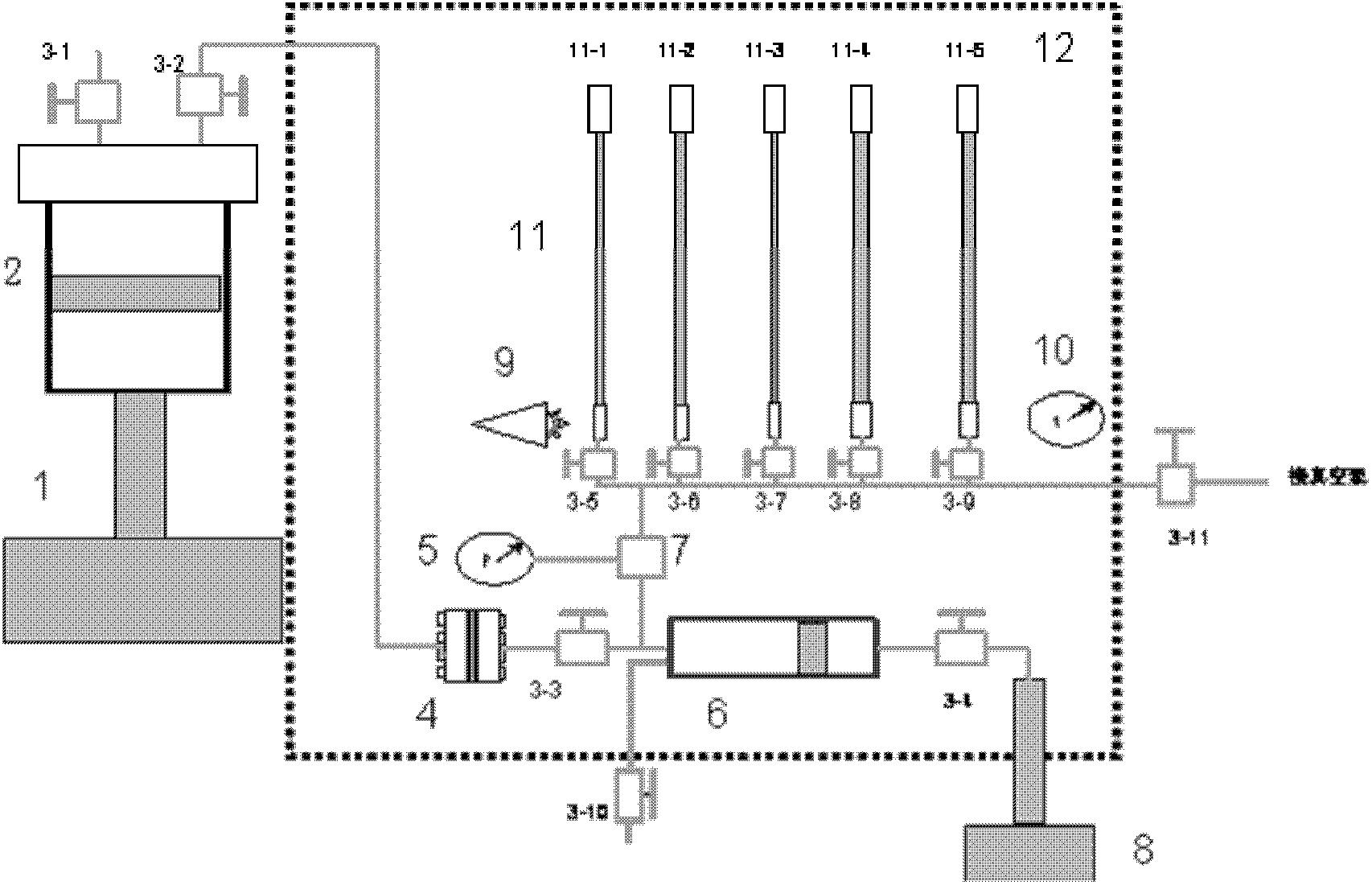

[0033] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0034] Such as figure 1 As shown, a device for testing the viscosity of heavy oil at the site of drilling and coring, said device comprises a squeeze pump 1, a rock sample chamber 2, a thermostat box 12 (or a thermostat jacket) and a valve 3-2; the squeeze pump 1 and The rock sample chamber 2 is connected, and the rock sample chamber 2 is connected with the thermostat 12 through the second valve 3-2; the extrusion pump 1 is used to squeeze out the crude oil in the rock sample in the rock sample chamber 2 and pass through the valve 3-2. 2 into the porous filter 4. The rock sample chamber 2 is used to place cuttings or rock blocks obtained during drilling and coring. A valve 3-1 is also connected to the rock sample chamber 2 for discharging gas and venting in the rock sample chamber 2;

[0035] Squeeze pump 1 can adopt electric hydraulic press or manual hydraulic pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com