Method and apparatus for applying liquid material, and program

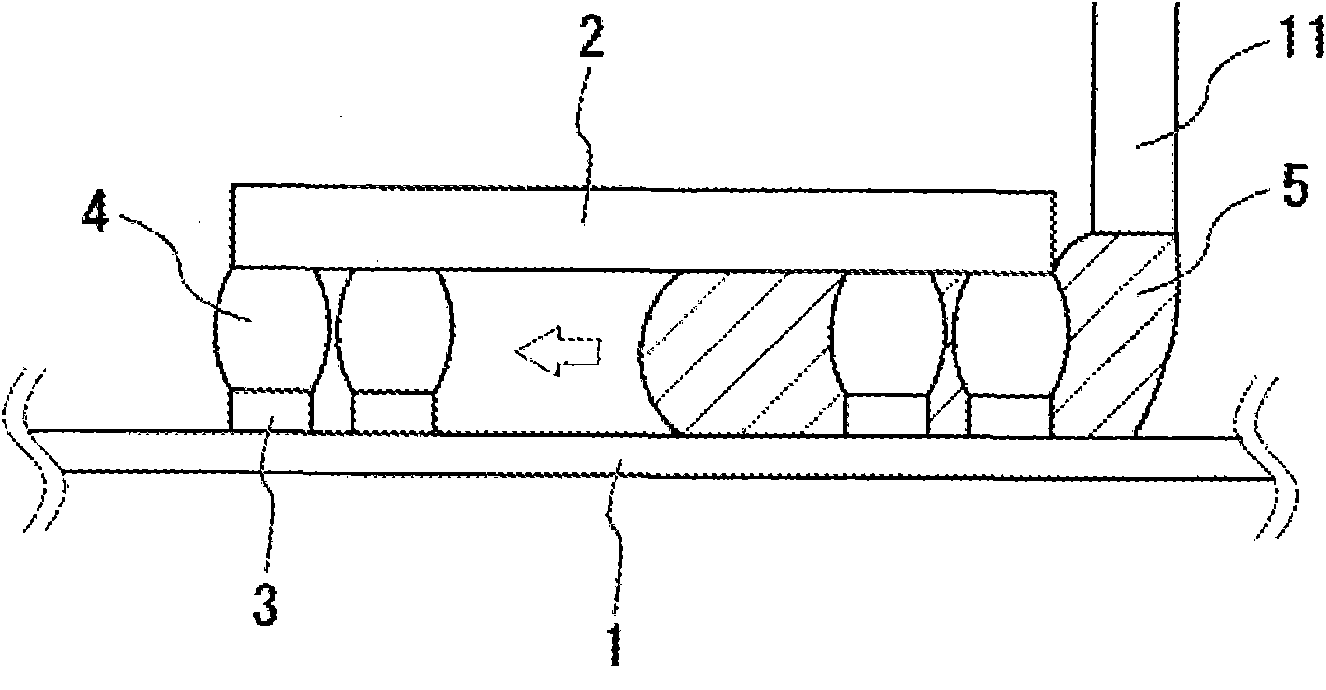

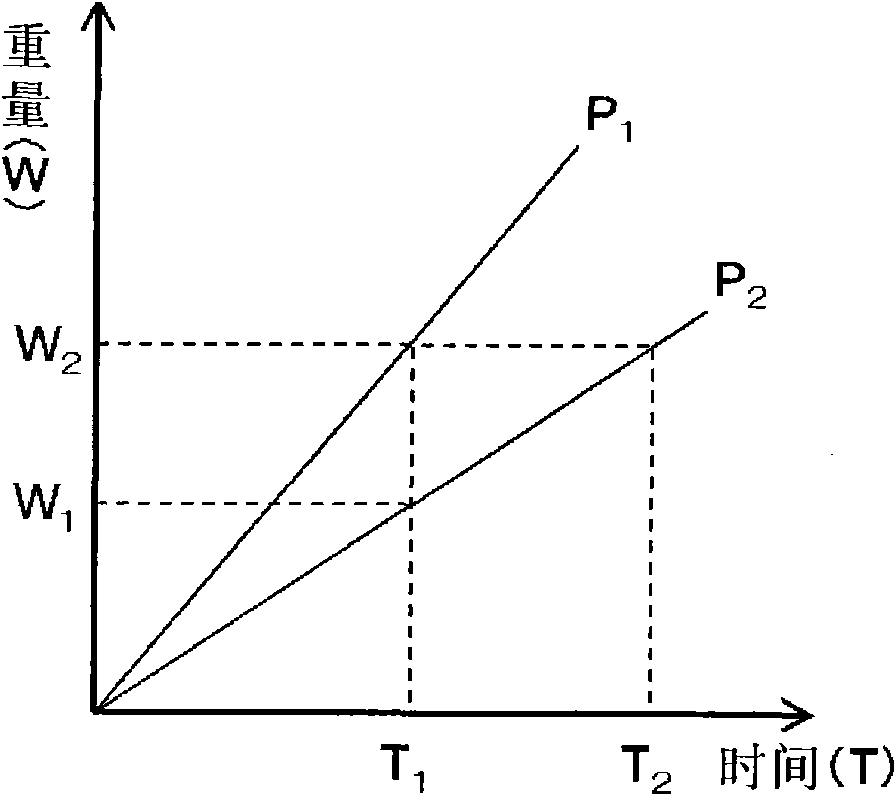

A technology of liquid materials and filling methods, which can be applied to devices for coating liquid on the surface, electric solid devices, semiconductor devices, etc., and can solve problems such as reduced discharge volume and insufficient capillary tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The best mode for implementing the present invention will be described below.

[0085] (1) Formation of overall coating pattern

[0086] Make one or more overall coating patterns, choose one of them. The overall coating pattern is composed of multiple correction coating patterns, or a combination of more than one non-correction coating pattern and one or more correction coating patterns, and at least one correction coating pattern must be present. For example, if Image 6 As shown, a corrected coating pattern 14 composed of alternately continuous coated areas 12 and non-coated areas 13 is made along a line along one side of a square workpiece, that is, a chip 2, and the entire length of the corrected coated pattern 14 is formed. The overall coating pattern is composed of the same non-correction coating pattern 15 consisting only of the coating area 12 along one side of the same chip 2 . Furthermore, the workpiece is not limited to a square shape, and may be circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com