Measurement device for tangent circle diameter of fuel nozzle of power station boiler and measurement method thereof

A technology for measuring devices and power plant boilers, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of complex measuring equipment, rough measurement data, and low accuracy, and achieve simple measuring equipment, reduce coking accidents, and be easy to be accurate The effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

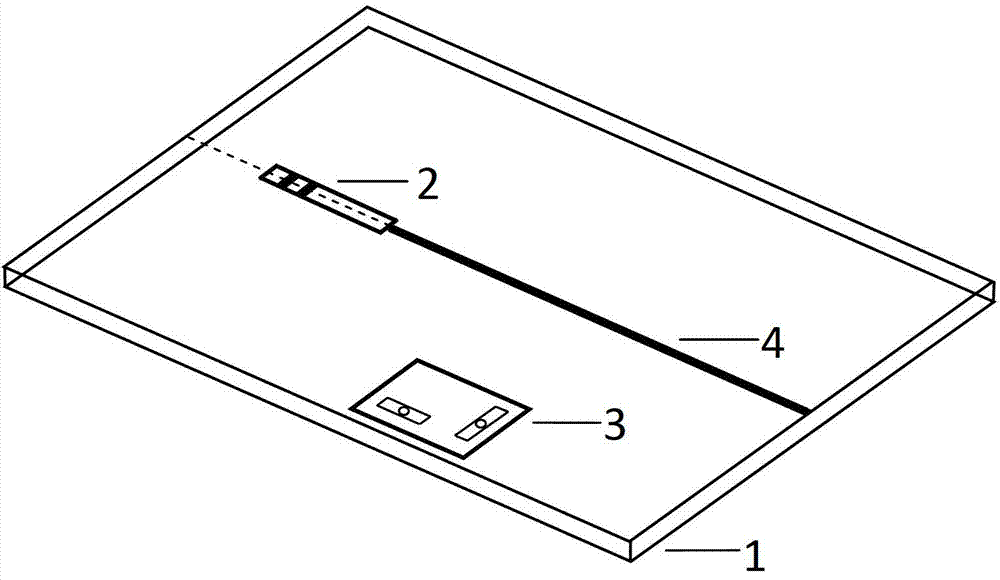

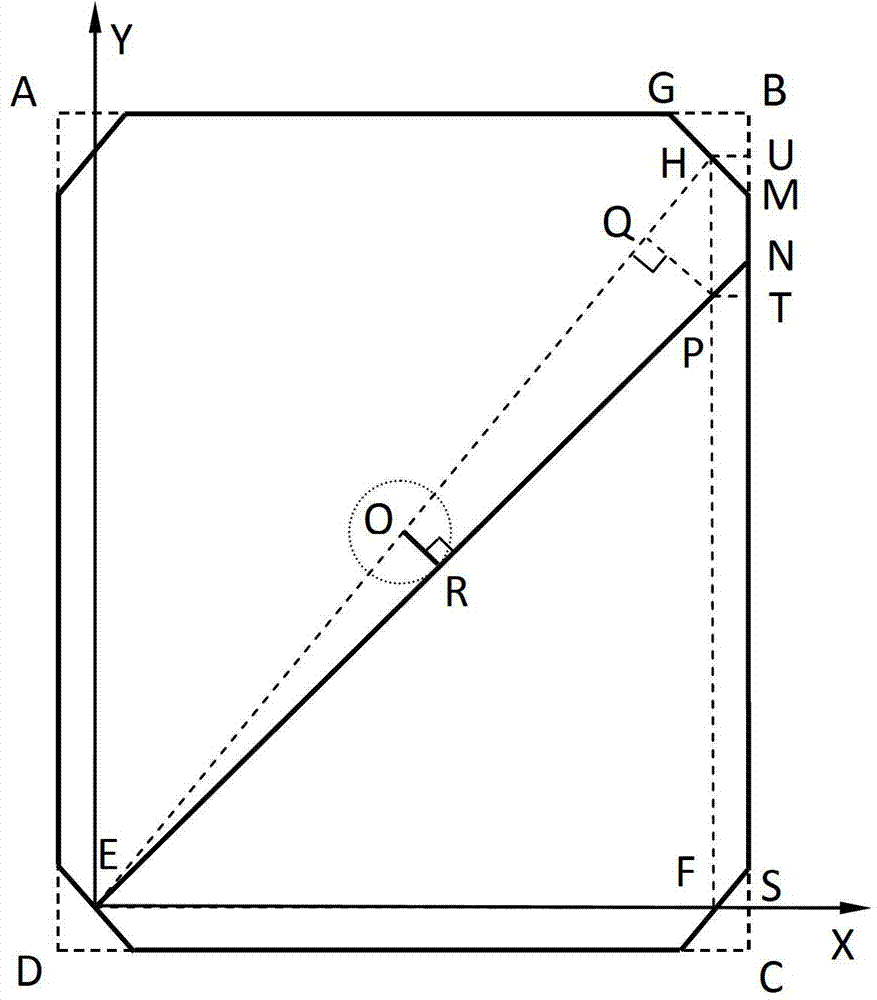

[0037] like figure 1 As shown, a power plant boiler burner tangential circle diameter measuring device includes a rectangular steel plate 1, an infrared generator 2, and a level 3; the infrared generator 2 is installed in a slot on the longitudinal centerline of the surface of the rectangular steel plate 1; the Said spirit level 3 is installed in the draw-in groove of a corner of rectangular steel plate 1 surface. The infrared ray 4 emitted by the infrared ray generator 2 coincides with the longitudinal midline of the rectangular steel plate 1 .

[0038] The 3# unit of a power generation company had serious coking phenomenon, and two coke loss and fire extinguishing accidents occurred in a relatively short period of time, which seriously threatened the safety of the unit and power grid equipment. The company immediately set up an expert group to anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com