Multi-layer bubbled foil radial dynamic pressure gas bearing

A technology of dynamic pressure gas bearings and bubble foils, which is applied in the direction of sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of restricting the application of turbomachinery, poor load adaptability, unbearable load, etc., and improve friction damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

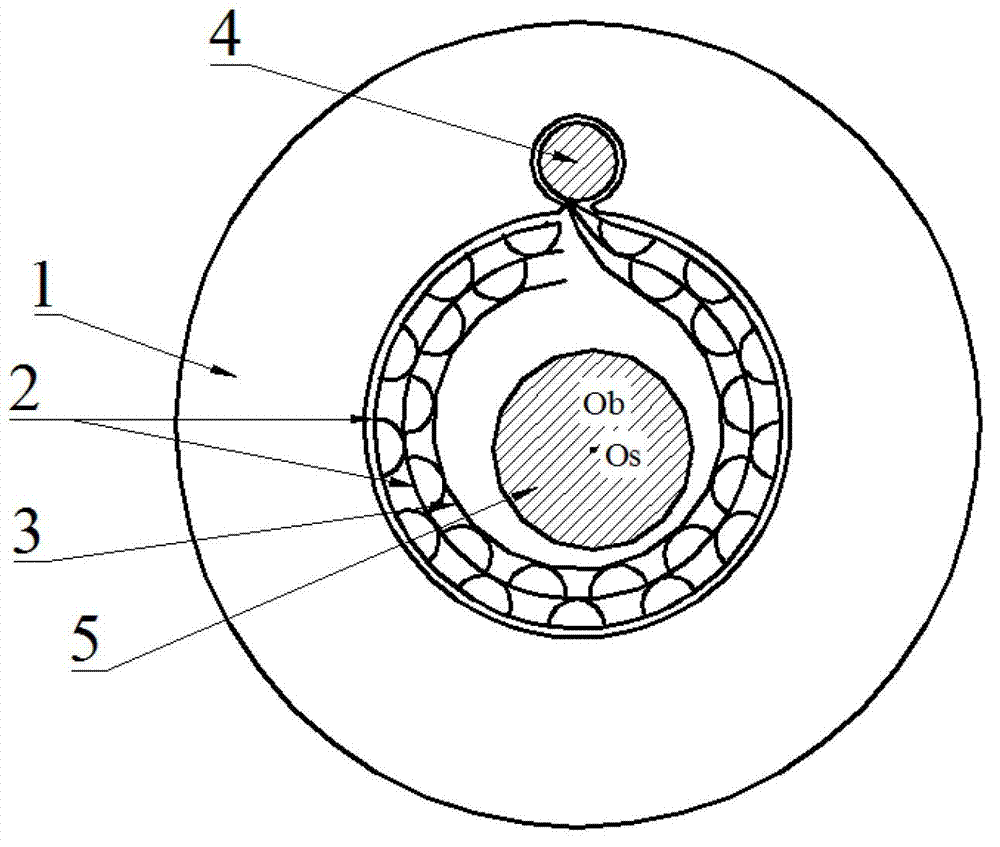

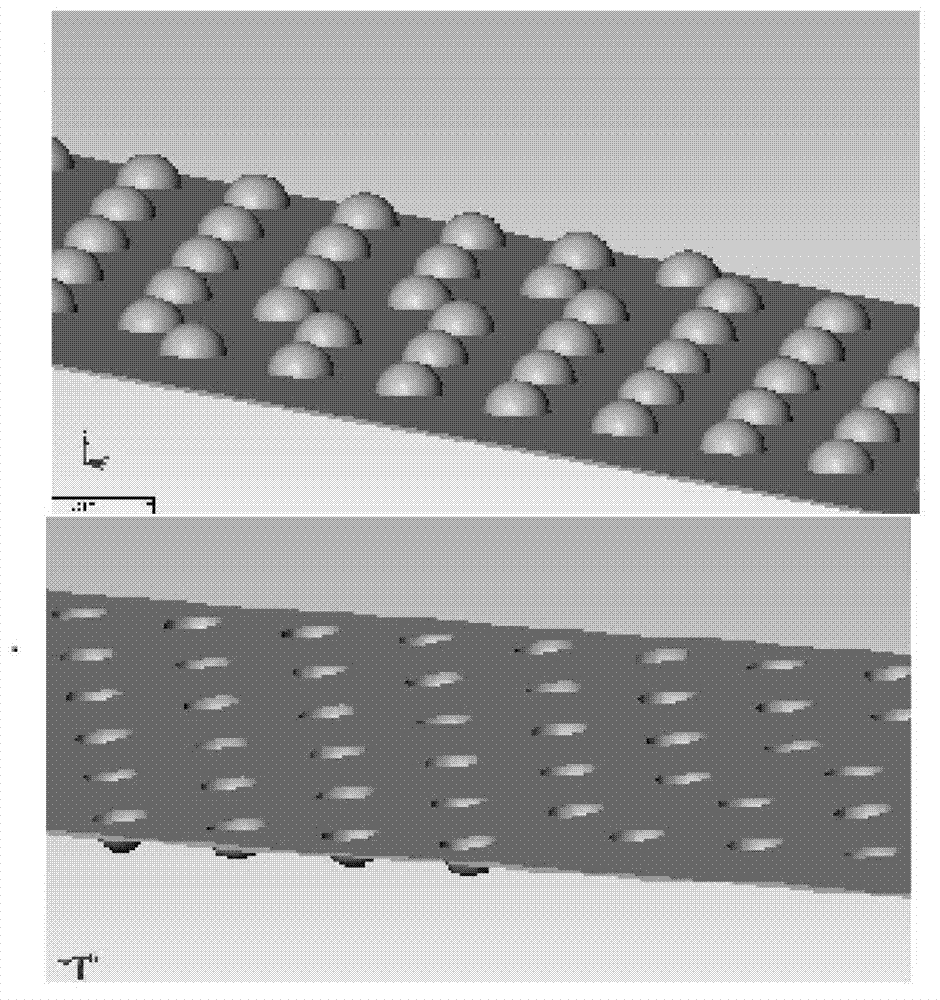

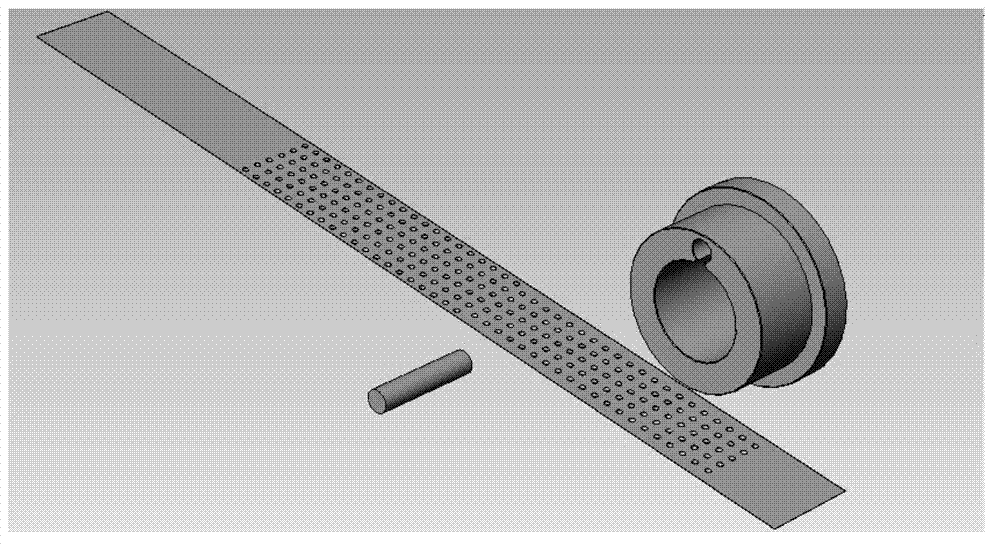

[0029] see figure 1 , a multi-layer bubbling foil radial dynamic pressure gas bearing, including a bearing seat 1 and a shaft arranged in the bearing seat 1, an elastic support assembly is arranged inside the bearing seat 1; the elastic support assembly includes an elastic support assembly arranged inside the bearing seat 1 The multi-layer elastic bubble element 2 and the top layer flat foil 3 arranged between the elastic bubble element 2 and the shaft, the top layer flat foil 3 is pasted on the elastic bubble element 2; each layer of elastic bubble element 2 is provided with There is a shell-shaped protrusion with a continuous transition surface; one end of the elastic support component is fixed on the bearing seat 1 through the positioning element 4, and the other end is free.

[0030] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com