Coal bed methane production method in radial well drilled with support pipe and gas jet

A mining method and a technology for supporting pipes, which are applied to drilling with liquid/gas jets, drilling equipment and methods, and production fluids, etc., can solve the problems of low gas production, complex process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

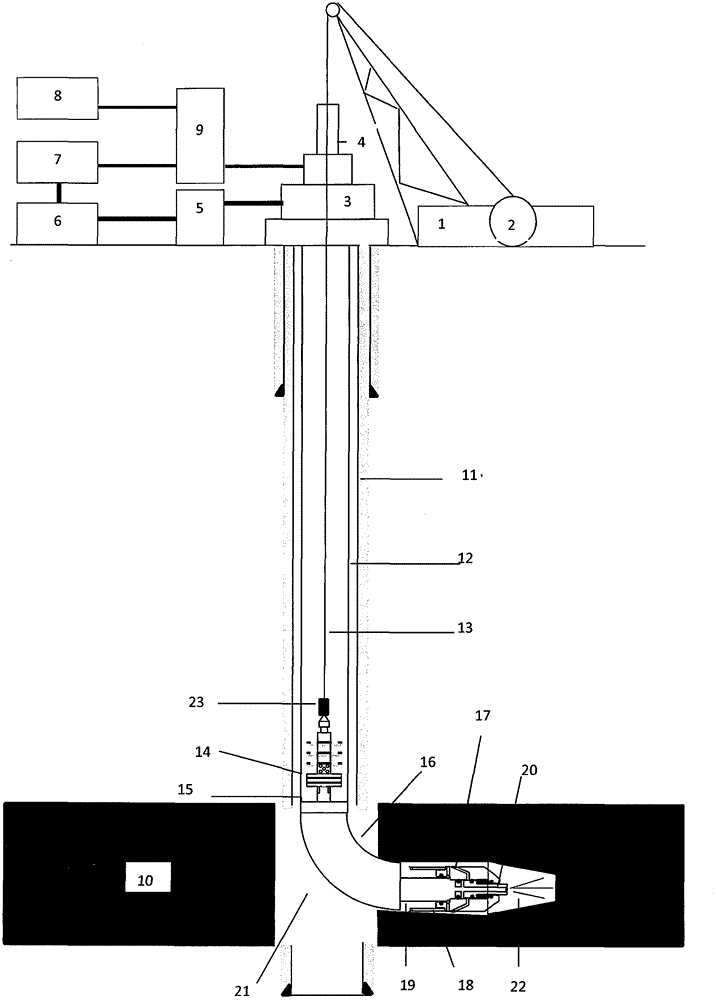

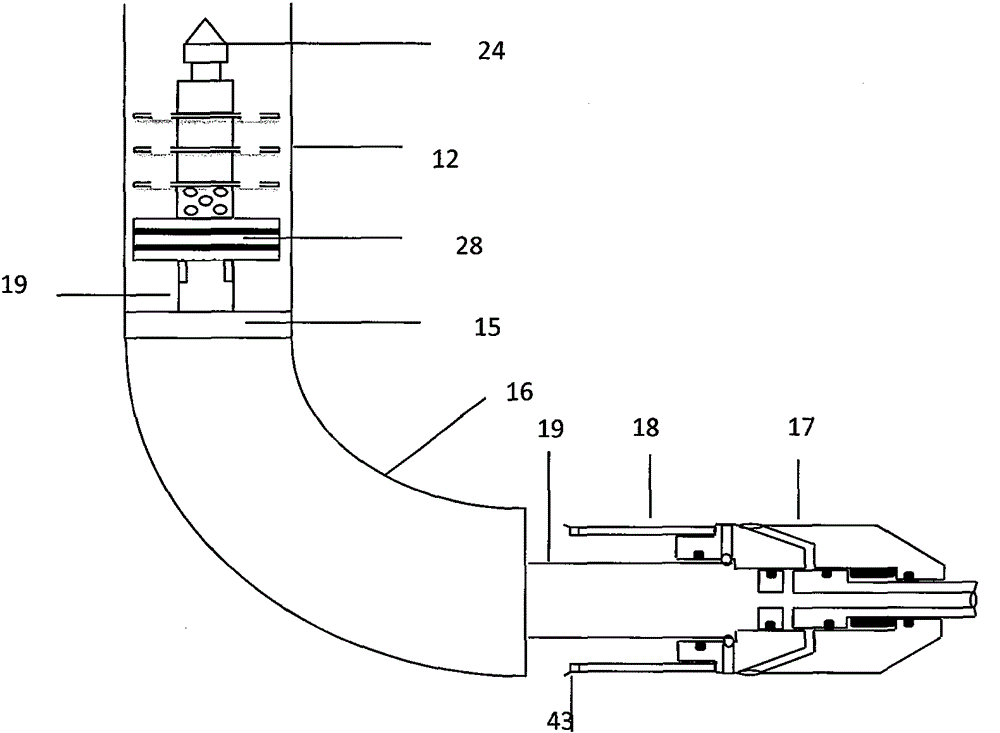

[0023] Such as figure 1 As shown, the reaming of the well section of the coal seam 10 is to use a mechanical or hydraulic reamer to ream the hole in the well section of the coal seam 10 to a cave 21 with a diameter of about 500 mm. Its function one is to eliminate the pollution of drilling and cementing to the coal seam, and the other is to provide a preliminary bending space for the radial orientation tool 16, so that the radial orientation can be realized.

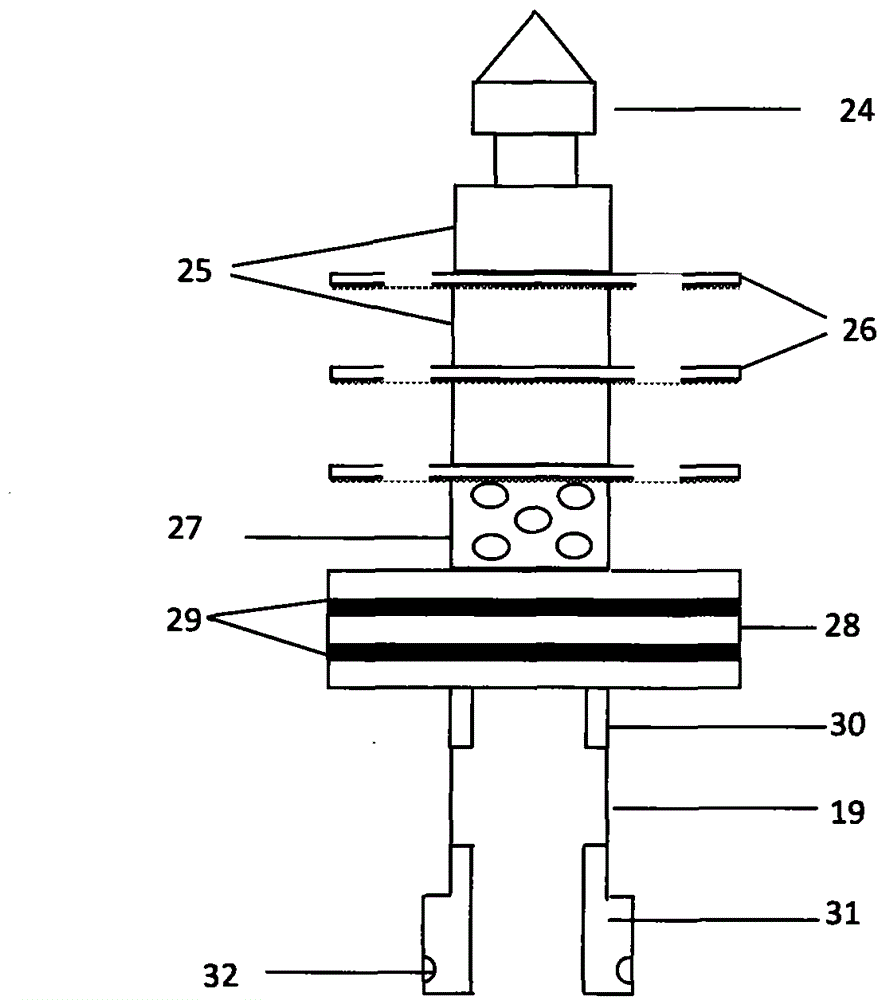

[0024] Such as figure 1 As shown, the wire rope 13 is connected with the ground winch 2 on the top, and is connected with the rope fishing head 24 on the support pipe follow-up injection tool assembly 14 through the fishing rope cap 23, and its function is to lift up and down through the ground winch 2. The support pipe follows the jet drilling tool assembly to control the jet drilling speed and the WOB applied to the crawling jet 17 .

[0025] Such as figure 1 As shown, the spraying forms the radially curved well sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com