Optically-transparent dual-curing adhesive

An optically transparent, adhesive technology, applied in the direction of adhesive types, non-polymer organic compound adhesives, ester copolymer adhesives, etc., can solve the corrosion of unbonded parts, and the adhesive cannot be fully cured , peeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0102]

[0103] The adhesive composition of the present invention can be prepared by adding and mixing the components of the adhesive composition described above in set proportions in a substantially light-proof mixing vessel with conventional stirring means. Mixing is usually carried out at ambient temperature, but may also be carried out at a temperature slightly higher or lower than ambient temperature. The mixing should be carried out for a period of time long enough to obtain a homogeneous combination of the components, thereby obtaining the adhesive composition. The thus obtained adhesive composition is stored away from light; it is used for subsequent bonding between the touch screen of the optoelectronic product and the substrate.

[0104] The volume of the mixing container is not specifically limited, and it may be, for example, about 1-100 L, or 5-50 L, or 10-30 L, etc. according to specific preparation requirements. The mixing vessel can be a commercially availab...

Embodiment 1

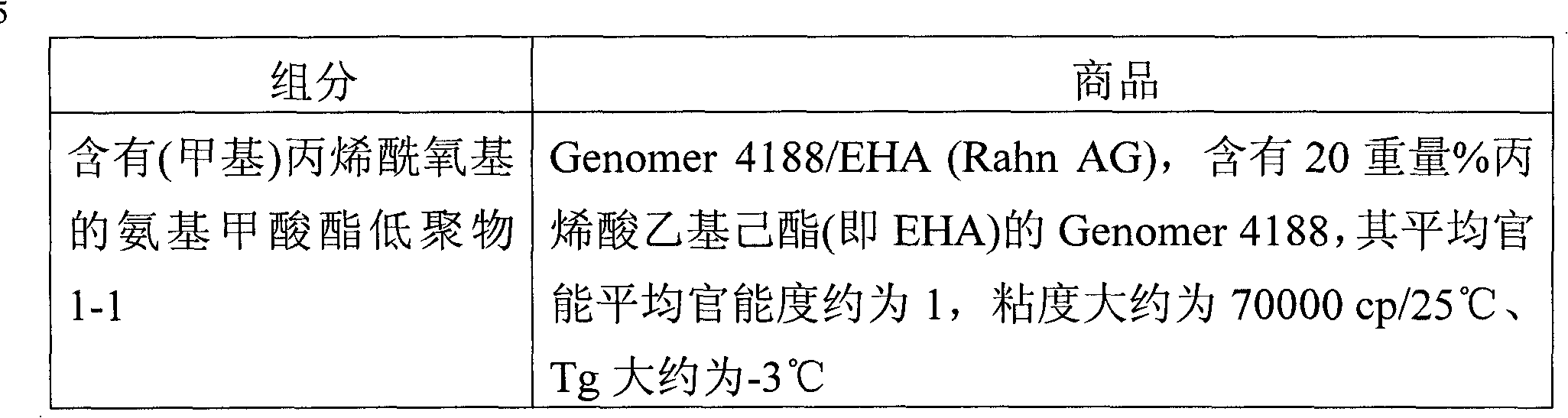

[0138] Embodiment 1 (according to the present invention)

[0139] Adhesive composition 1 was prepared according to the composition and preparation method of the following table 1:

[0140] Table 1

[0141] components

Content

Urethane oligomers 1-1 containing (meth)acryloyloxy groups

70 parts by weight

10 parts by weight

7 parts by weight

7 parts by weight

UV photoinitiator 5-1

2 parts by weight

UV photoinitiator 5-2

1 part by weight

Thermal Initiator 6-1

2 parts by weight

Thermal Initiator 6-2

1 part by weight

[0142] The preparation method of adhesive composition is as follows:

[0143] Under the condition of avoiding light, the above-mentioned components (total 100g) were added successively in the plastic barrel with a capacity of 150g, and put into the SpeedMixer produced by FlackTech Inc. TM In the mixer, at...

Embodiment 2

[0144] Embodiment 2 (according to the present invention)

[0145] Adhesive composition 2 is prepared according to the composition of the following table 2 and the preparation method as in Example 1:

[0146] Table 2

[0147] components

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com