Magnetic Prussian blue pigment and preparation method thereof

A technology of Prussian blue and pearlescent pigments, applied in the direction of inorganic pigment treatment, chemical instruments and methods, fibrous fillers, etc., can solve problems such as unsuitable and restricted fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

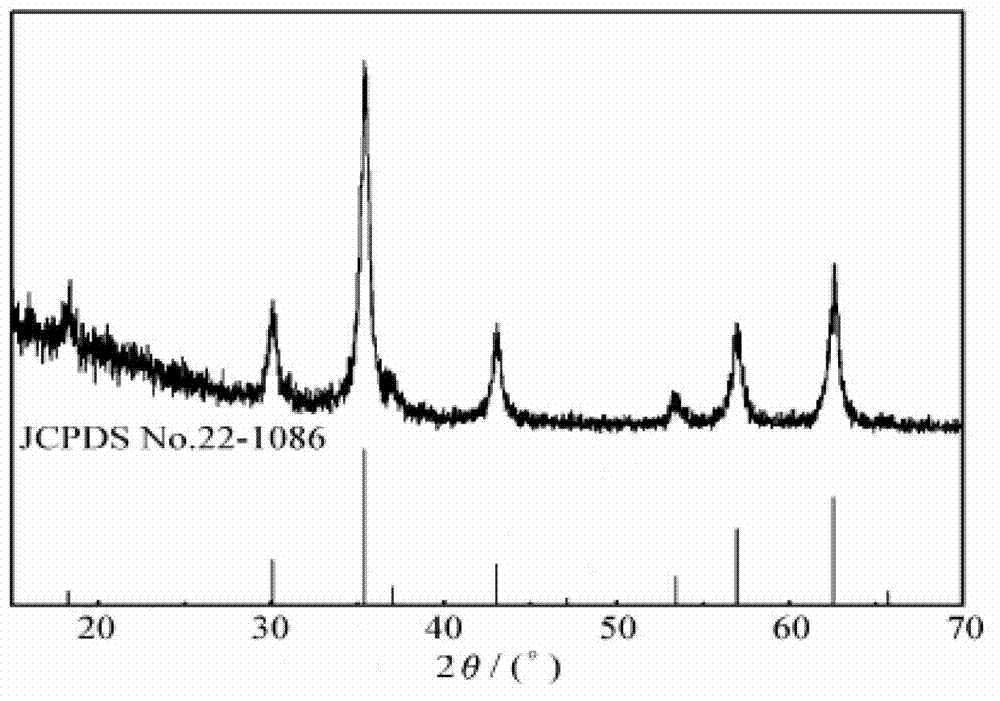

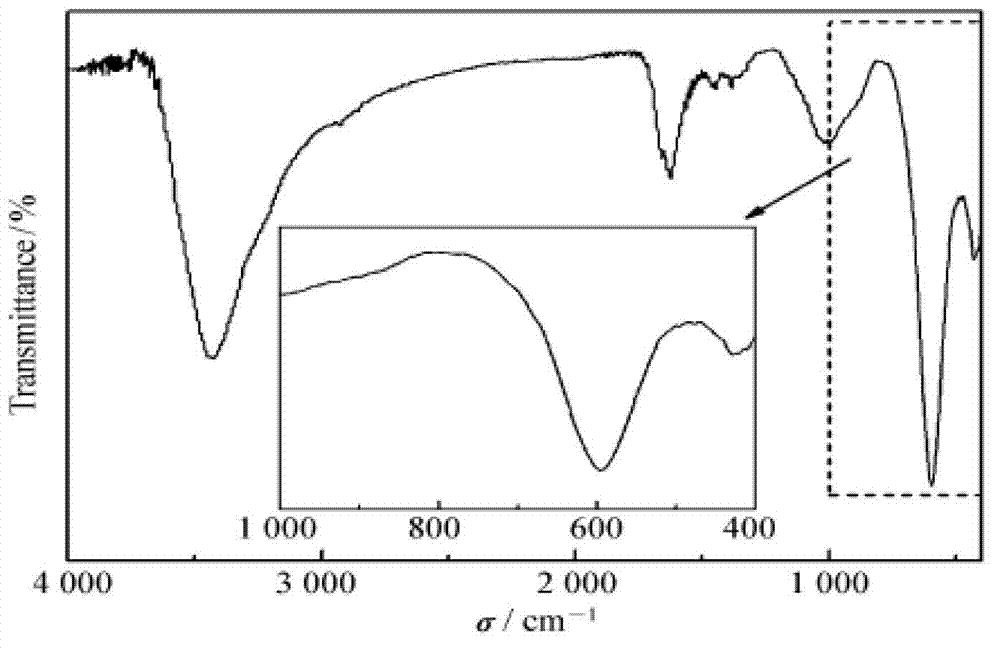

[0093] Preparation Example 1-magnetic black pearlescent pigment coated with a cobalt ferrite layer on a mica substrate:

[0094] (1) In a 2L beaker, disperse 100g of natural mica (average particle size 20μm, average thickness 1.5μm) in 1000ml of deionized water to obtain a suspension (called suspension A-1), at a stirring speed of 400 rpm Heat to 78°C for 1 minute and adjust pH=3.0 with 1:1 HCl.

[0095] (2) With a drop rate of 1.1g / min, add 39wt% FeCl to the above suspension A-1 3 Solution 80ml and use 25% NaOH to keep the pH value of the solution constant at 3.0.

[0096] (3) Use 25wt% NaOH solution to adjust the pH of the above mixture to 9.0, and add 8wt% CoSO at a drop rate of 0.8ml / min 4 Solution 90ml, and use 25% NaOH to keep the pH value of the solution constant at 9.0.

[0097] (4) Suction filter the above mixture, wash with deionized water, dry at 120°C for 2 hours, and finally calcined at 800°C for 20 minutes to obtain a black pearlescent pigment (MP-1), and meas...

preparation Embodiment 2

[0102] (1) In a 2L beaker, disperse 100g of natural mica-coated TiO2 interference blue pearlescent pigment (KC225 blue pearlescent pigment) with an average particle size of 20um in 1000ml of deionized water, and heat it to 78C, adjust pH=3.0 with 1:1 HCl.

[0103] (2) With a drop rate of 1.1g / min, add 39% FeCl 3 Solution 60ml and use 25% NaOH to keep the pH value of the solution constant at 3.0.

[0104] (3) Use 25% NaOH solution to adjust the pH of the above mixture to 9.0, and add 70ml of 8% CoSO4 solution at a drop rate of 0.8ml / min, and use 25% NaOH to keep the pH value of the solution constant.

[0105] (4) The above mixture was washed with deionized water, dried at 120°C for 2 hours, and finally calcined at 800°C for 20 minutes to obtain a black pearlescent pigment (MP-2). The thickness of the ferrite layer was measured to be 25nm.

[0106] The saturation specific magnetization (Ms) was detected with a Sigmameter specific saturation magnetization tester, and the satura...

preparation Embodiment 3

[0108] Repeat Example 1 of Chinese Patent Publication CN101460574A (Application No. 200780020908.7) to finally obtain a black pearlescent pigment (MP-3), and measure the thickness of the ferrite layer to be 50 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com