On-line detecting device and method for descending brake distance of crane hoisting mechanism

A technology of lifting mechanism and braking distance, which is applied in hoisting device, clockwork mechanism, transportation and packaging, etc. It can solve the problems of excessive sliding amount, threat to the safe operation of hoisting machinery, and failure to do so, so as to achieve guarantee Operational safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiment 1 uses an incremental encoder 3 to detect the displacement, and the incremental encoder 3 is installed at the shaft end of the reel.

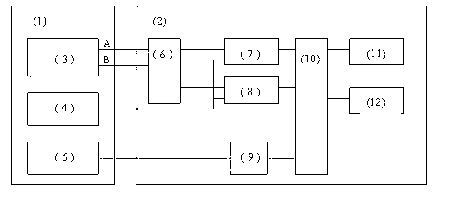

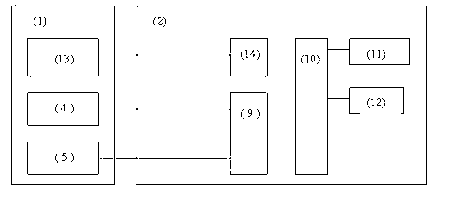

[0041] figure 1 It is a structural diagram of an online detection device for the braking distance of a crane hoisting mechanism using an incremental encoder 3, including a crane operating condition signal detection part 1 and a measurement recording part 2.

[0042] The crane operating condition signal detection part 1 includes an incremental encoder 3 , a brake power-off detection unit 4 and a lifting direction detection unit 5 .

[0043] The measurement and recording part 2 includes a controller 10 , a direction pulse detection unit 6 , forward and reverse counting units 7 and 8 with counting enable control terminals, a signal interface unit 9 , a display and operation unit 11 and a data storage unit 12 .

[0044] Incremental encoder 3 orthogonal square wave pulses A and B are connected to direction pulse detection unit 6; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com