A crane load space swing angle detection technology and device

A crane and space technology, which is applied in the field of space attitude measurement technology and device of crane load, can solve problems such as high measurement environment requirements, and achieve the effects of convenient use, small size and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

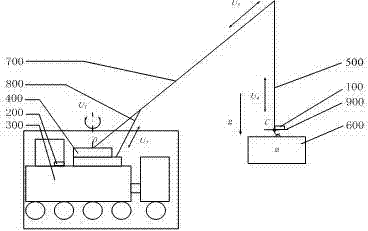

[0029] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings, taking a truck crane as an example.

[0030] Such as figure 2 As shown, the truck crane includes: a measuring box 100 , a signal processing receiver 200 , a car body 300 , a slewing mechanism 400 , a lifting rope 500 , a load 600 , a boom 700 , a pitching mechanism 800 and a hook 900 . The boom 700 of the truck crane can be telescopic, and under the action of the pitching mechanism 800, it can move in pitch. The measurement box 100 is fixed on the hook 900, and the signal processing receiver 200 is installed in the control box of the crane.

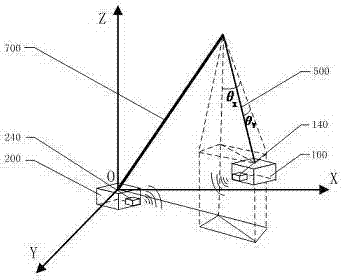

[0031] The detection idea of the swing angle of the load space of the crane in the present invention can be combined with figure 1 illustrate. The measuring box 100 is installed on the hook / load at the end of the sling 500, and its function is to use the MEMS technology-based three-degree-of-freedom m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com