Vehicle tire burst remedying device

A tire blowout, vehicle technology, applied to vehicle parts, tire parts, transportation and packaging, etc., can solve problems such as difficult to achieve results, limited vehicle direction control compensation, etc., to eliminate the problem of steering out of control, reliable principle, overall structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

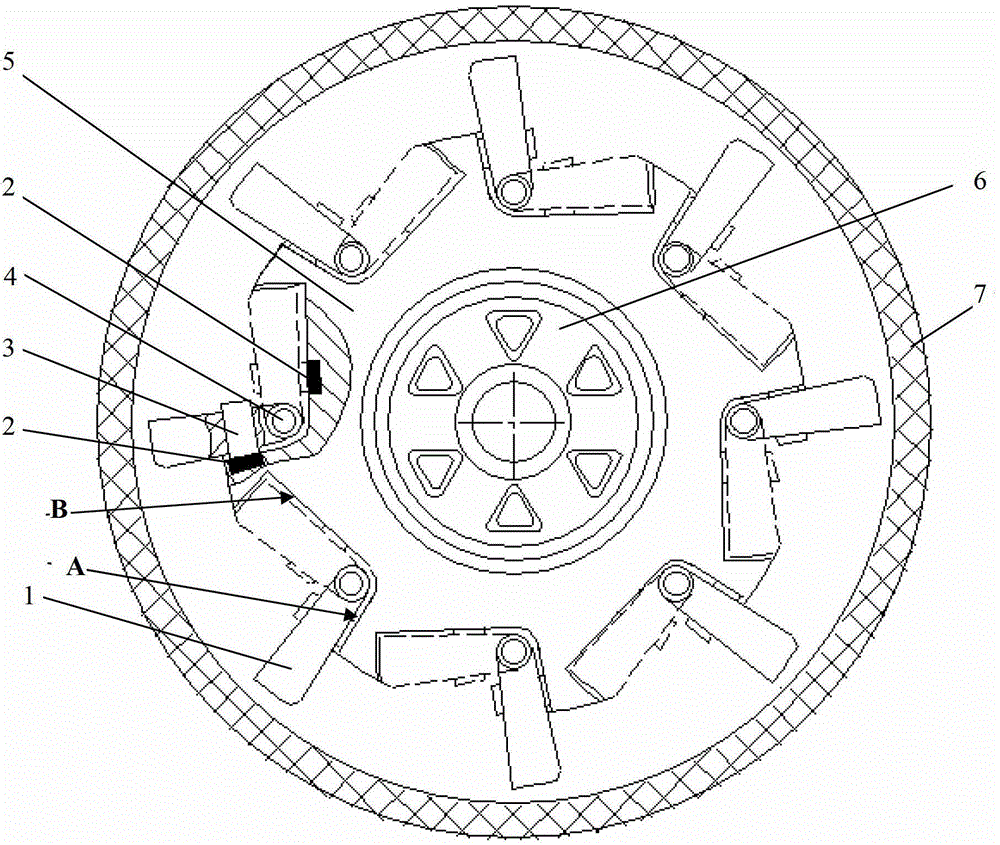

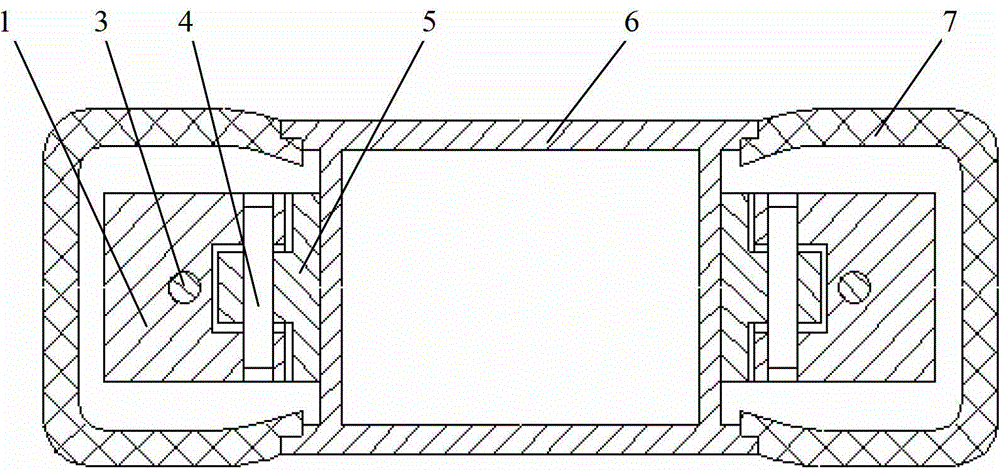

[0011] The main structure of the present embodiment comprises a support column 1, a metal block 2, a magnetic block 3, a fixed pin 4, a bearing 5, a rim 6 and a tire 7; Support 5, 6-12 bracket type support columns 1 with symmetrical structure are evenly distributed on the circumference center line ring of support 5, and fixed pin shaft 4 is formed at the intersection of each support column 1, and the support column 1 A lath-shaped magnetic block 3 is fixed, and a metal block 2 is fixed at one end of the magnetic block 3; the support column 1 is made of metal or high-strength composite material, and the support column 1 is inlaid with a magnetic block 3 to support The column 1 is hinged on the support 5 by the fixed pin shaft 4, and rotates around the fixed pin shaft 4; The surface in the radial direction is the limit surface A of the support column 1, and the support surface B perpendicular to the limit surface A is the support surface B of the support column 1. On the limit s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com