Shock-absorption air cushion for shoe and manufacturing method for shock-absorption air cushion

A technology for a shock-absorbing air cushion and a manufacturing method, which is applied to footwear, footwear, soles, etc., can solve the problems of inability to achieve a two-color upper and lower separation effect, a single internal shape and structure, and waste of shock-absorbing air cushion materials, and achieves appearance variability. , The appearance has the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to illustrate the idea and purpose of the present invention, the invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0032] A kind of manufacturing method of shock-absorbing air cushion for shoes of the present invention, it comprises the following steps:

[0033] A. Provide injection mold;

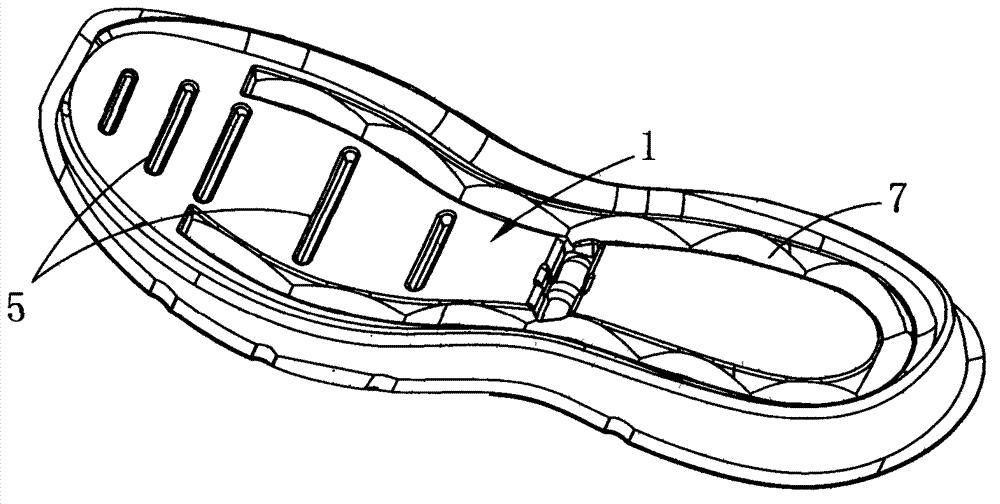

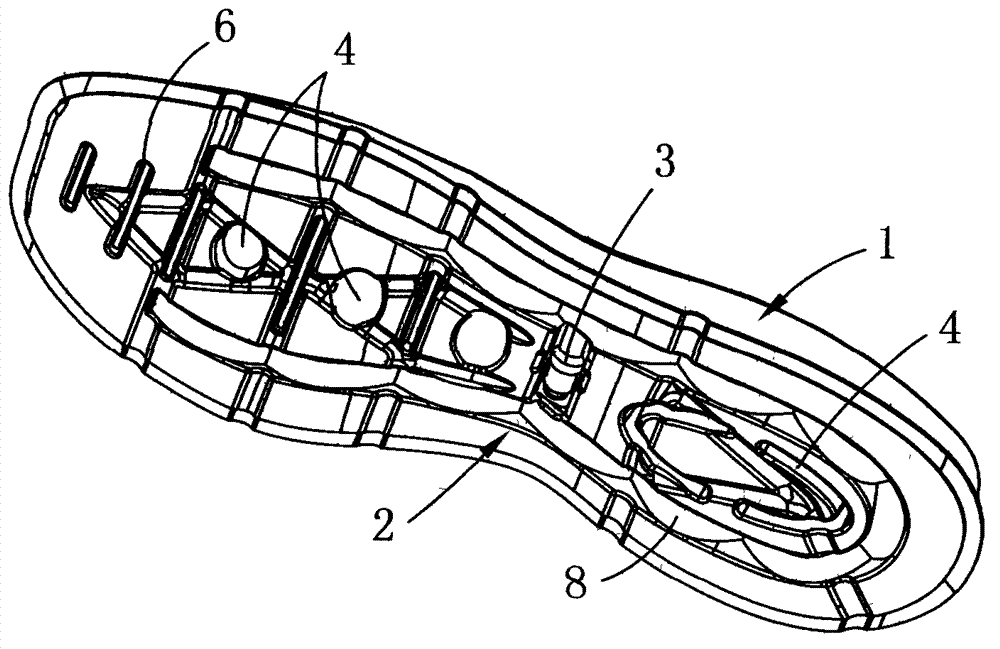

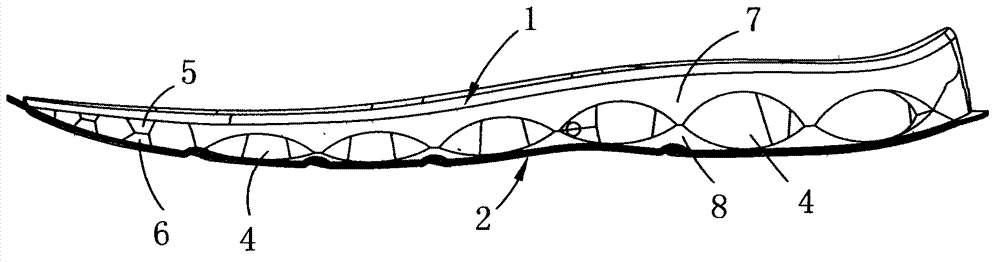

[0034] B. Inject the thermoplastic into the injection mold through the injection molding process. After the thermoplastic is cooled, an upper air cushion 1 and a lower air cushion 2 are formed in the two molding spaces of the injection mold, and the upper air cushion 1 and the lower air cushion 2 Separately formed support structures with variable appearance that can be designed and changed according to the stress points of the soles of the feet in different sports;

[0035] C. Open the mold, and demould the prepared air cushion upper sheet 1 and air cushion lower sheet 2;

[0036] D. Add the air nozzle 3 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com