Part diameter on-line control method of precise cylindrical grinding machine

A technology of cylindrical grinding machine and control method, which is applied in the direction of grinding machine parts, control of workpiece feed movement, manufacturing tools, etc. It can solve the problems of the influence of the rotation speed of parts and increase the probability of waste products, etc., and the solution is simple and easy to implement , high control precision and good processing repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

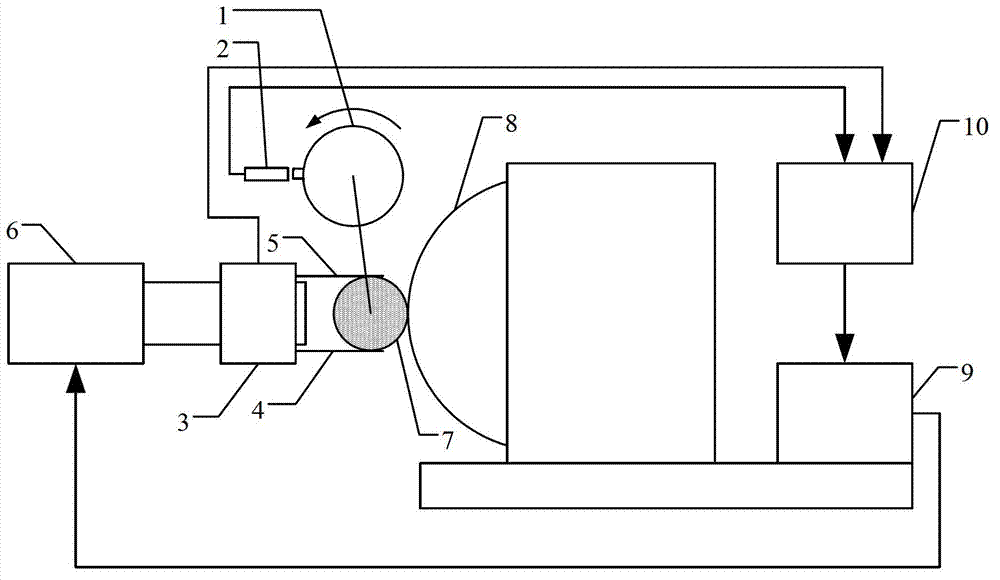

[0010] Such as figure 1 As shown, an on-line control method for part diameter of a precision cylindrical grinding machine is characterized in that:

[0011] A. Install a diameter measuring probe 3 on the outside of the part 7 and point to the part 7; the upper measuring arm 4 and the lower measuring arm 5 of the diameter measuring probe 3 are in close contact with the part, and the diameter measuring probe 3 is installed on the pneumatic telescopic platform 6. The telescopic platform 6 is controlled by the precision cylindrical grinding machine control system 9. Driven by the pneumatic telescopic platform 6, the diameter measuring probe 3 can enter the processing area to detect the diameter of the part and exit the processing area after the processing is completed;

[0012] B. Part 7 has a self-rotating drive swing head. Install a proximity sensor switch 2 beside the swing head output shaft 1 that drives the part to rotate. A raised mark is installed on the output shaft. Every...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com