Automatically-controlled hydraulic wire stripping pliers

A wire stripper and hydraulic technology, applied in the direction of line/collector parts, electrical components, equipment for dismantling/armored cables, etc., can solve problems such as low efficiency, inconvenient work, and heavy workload of aluminum stranded wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

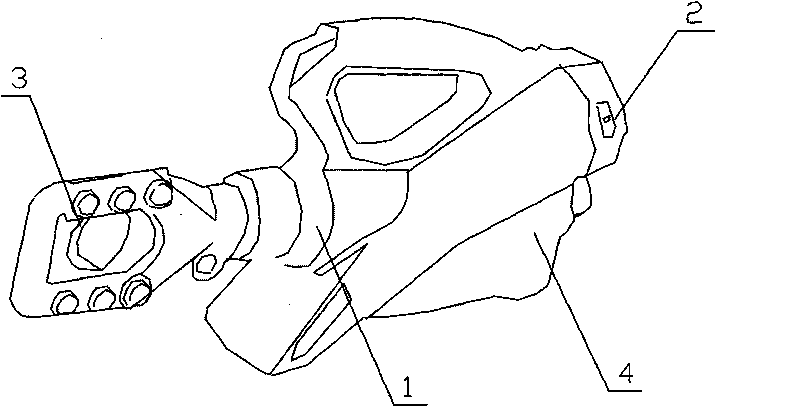

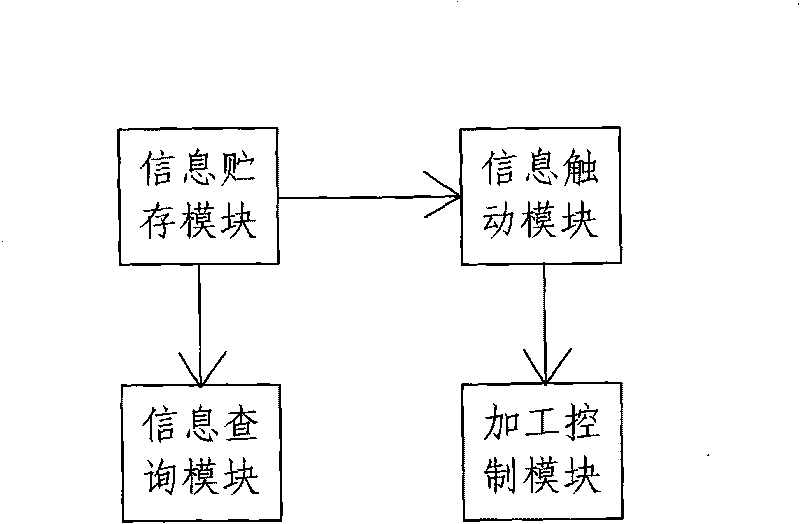

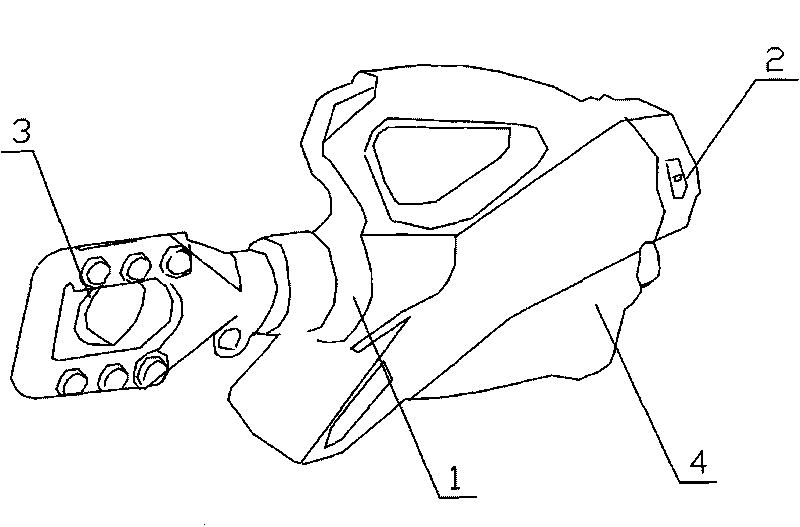

[0013] Such as figure 1 Shown: an automatic control hydraulic wire stripper, including a hydraulic transmission part, a cutting device, a pressure relief valve and a microcomputer control part, the microcomputer control part includes an information storage module, an information touch module, a processing control module and an information query module, The information storage module stores the structure, hardness, outer diameter of the wire and the outer diameter of the steel core of a large number of conventional wires, and the information trigger module can start the processing control module by inputting a certain type of wire in the microcomputer system , the processing control module automatically generates the cutting size of the knife edge according to the data information entered by the information touch module, and performs cutting under the premise of display. When the cutting size of the knife edge reaches a specified value, the processing control module automaticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com