Synchronous tension adjustment winding machine

A synchronous adjustment and winding machine technology, applied in the field of winding machines, can solve the problems of different tension, poor operability, wire breakage, etc., and achieve the effects of convenient and fast adjustment, strong pressure resistance, and uniform tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

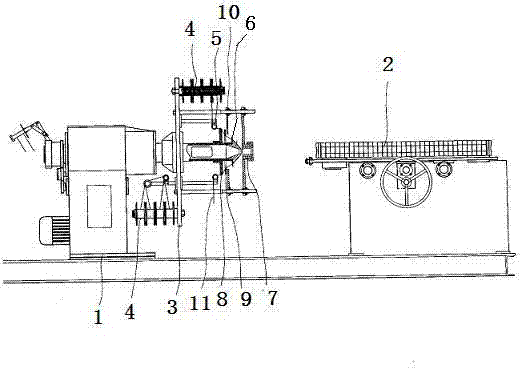

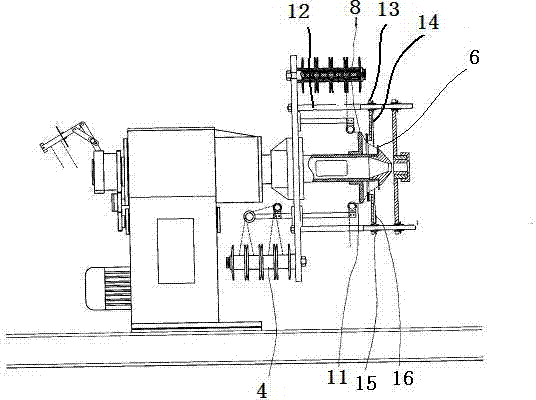

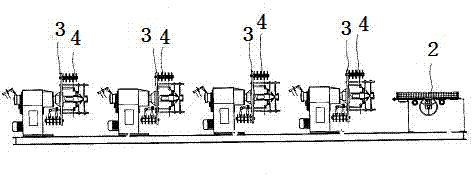

[0021] The structure of the tension synchronous adjustment winding machine proposed by the present invention will be further described below in conjunction with the accompanying drawings.

[0022] like figure 1 , figure 2 and Figure 5 Shown is a schematic diagram of the structure of the tension synchronous adjustment winding machine. Its structure includes a frame 1, a traction mechanism 2, a turntable 3, a pay-off mechanism 4, a pay-off direction change mechanism 5, a line distribution disc 6 and a mouth shape 7, and the side of the pay-off direction change mechanism 5 close to the line distribution disc 6 A fixed disk 8 is provided, and a tension adjustment ring 9 is provided on the side of the fixed disk 8 close to the line distribution disk 6. The tension adjustment ring is ring-shaped, and its inner diameter is smaller than the outer diameter of the fixed disk 8. Between the tension adjustment ring 9 and the fixed disk 8 They are connected by a position adjustment me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com