A rotary table filter gas-liquid distribution valve

A gas-liquid distribution and distribution valve technology, which is applied in the fields of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of reducing the maintenance time and maintenance cost of the turntable filter, and speeding up the flow rate of the filtrate, so as to avoid the scaling of the filtrate, the The effect of improving work efficiency and not easy to scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

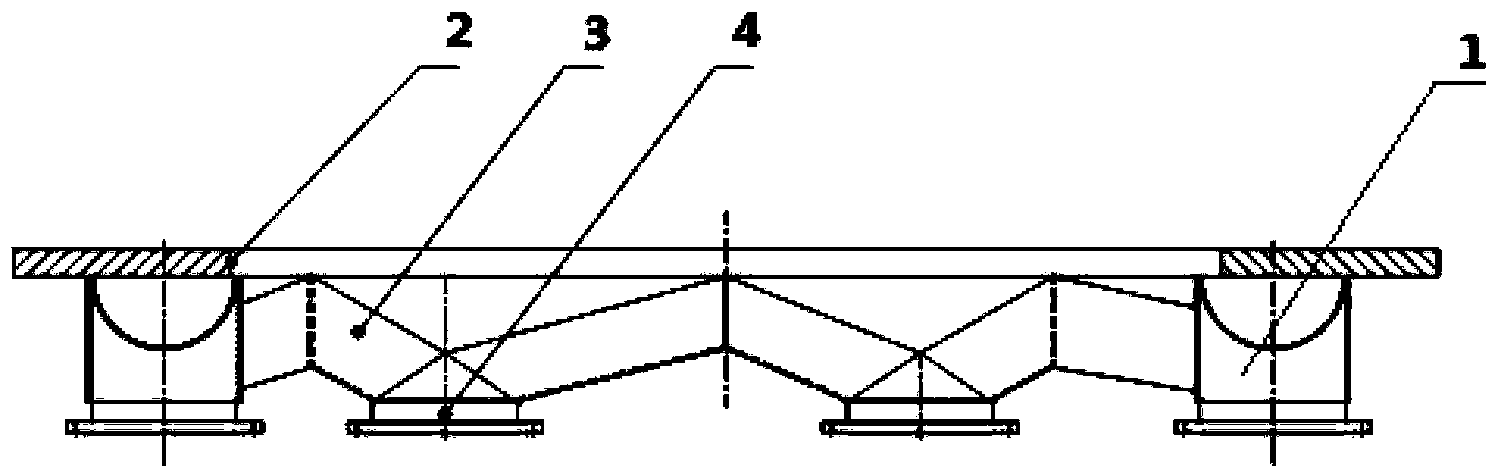

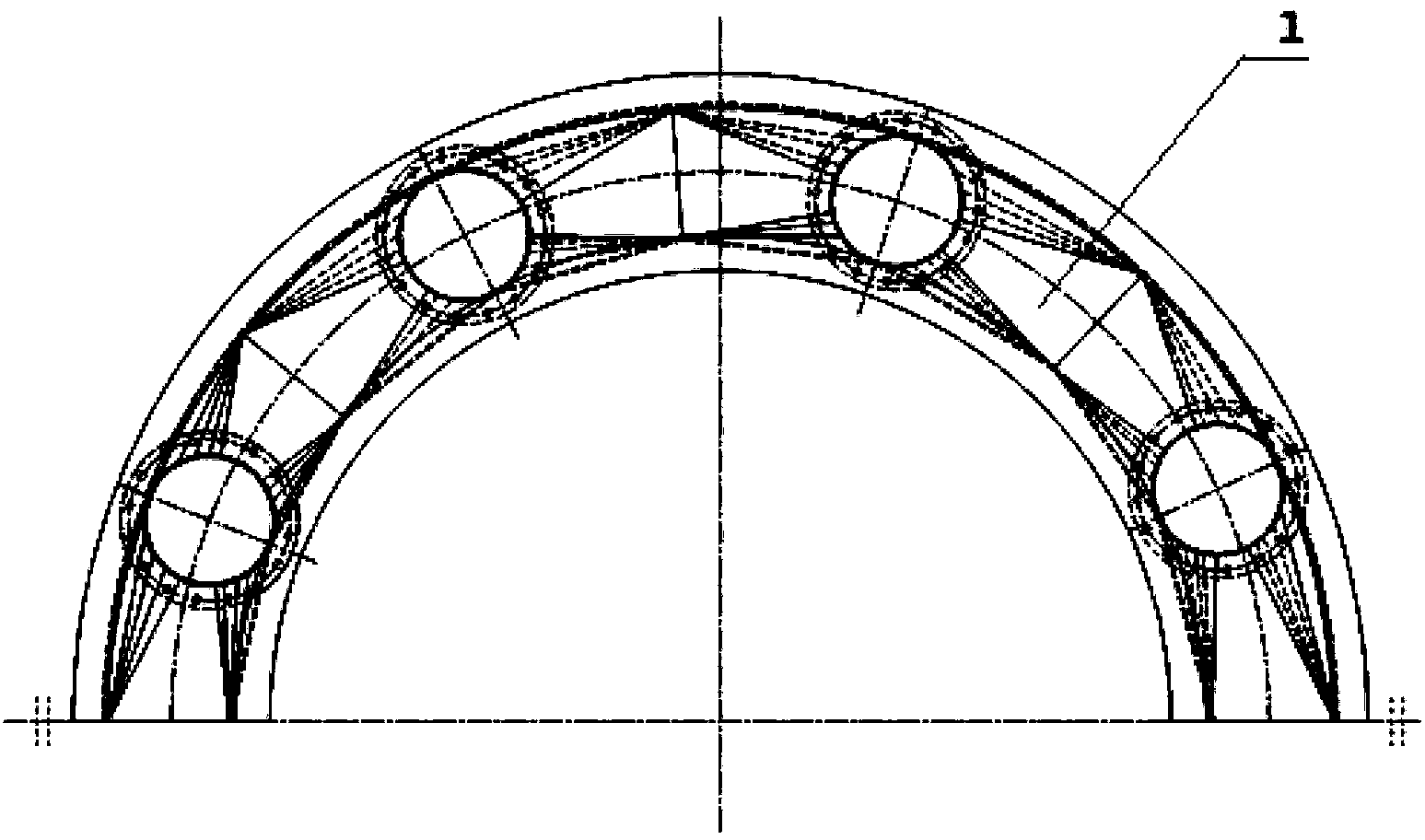

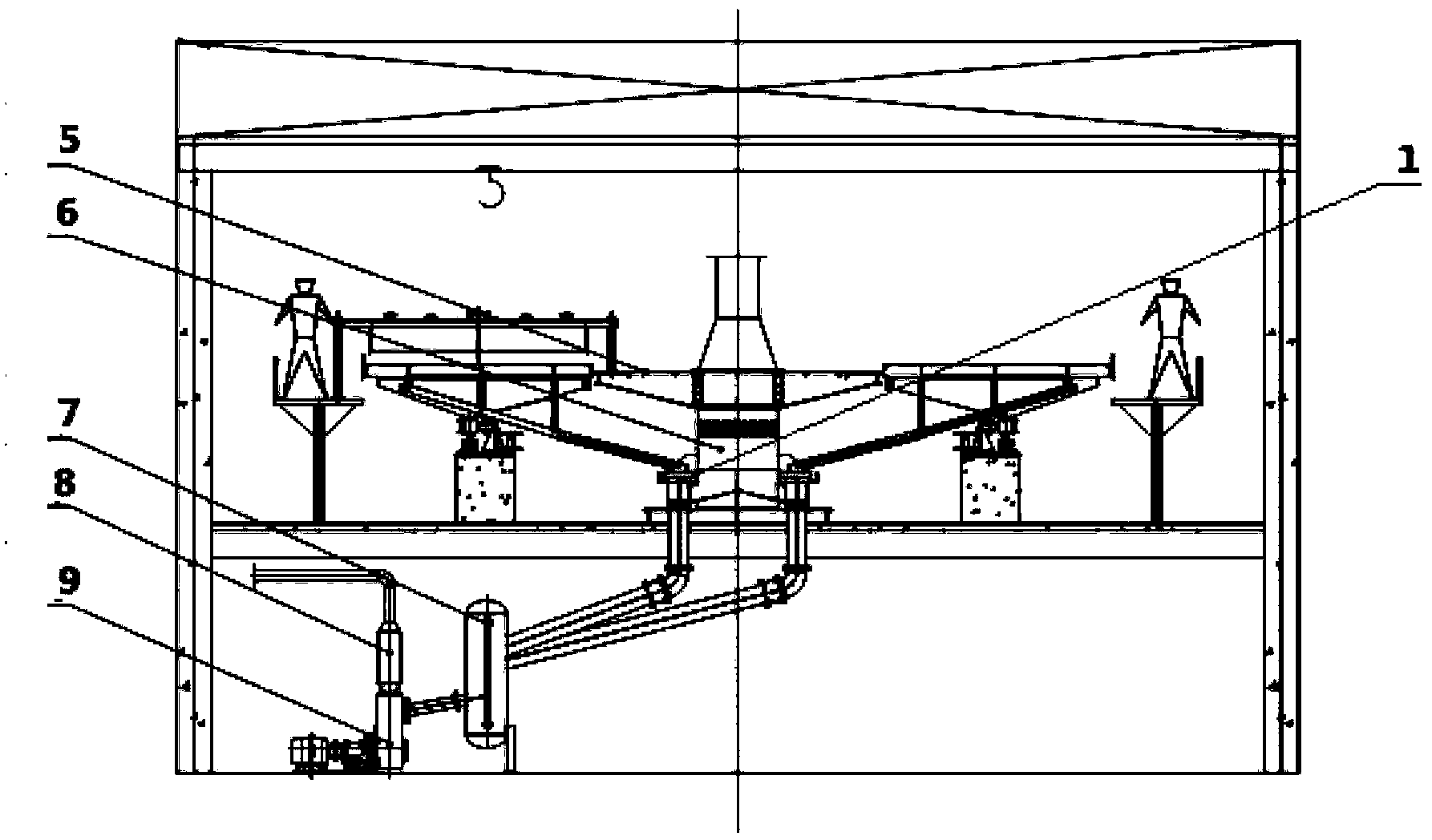

[0026] Such as Figure 1-3 As shown, the present invention provides a gas-liquid distribution valve for a turntable filter, the distribution valve is a gas-liquid distribution valve 1 for a filter, and the valve includes: a flange 2, a liquid guiding groove 3 and a liquid outlet 4. It is characterized in that the gas-liquid distribution valve 1 includes upper and lower layers respectively provided with upper and lower distribution valves; the upper distribution valve is provided with an opening matching the filtrate pipe of the filter and connected with the support frame of the filter The lower distributing valve is set on the central column 6 of the filter; the lower distributing valve is provided with an opening corresponding to the upper distributing valve and a liquid guiding groove 3 corresponding to the opening; The gas-liquid distribution valve 1 is provided with a central hole matching the central column 6 .

[0027] Wherein, the filter is a turntable filter, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com