Hydraulic Foam Control Valve

A foam control and valve body technology, applied in fire rescue and other directions, can solve the problems of reducing the strength and difficulty of assembling the foam control valve and pipe fittings, having no filtering and anti-backflow capabilities, and slow start-up of hydraulic ball valves, etc., so as to save electricity Control the logic circuit, put an end to false opening accidents, and avoid adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

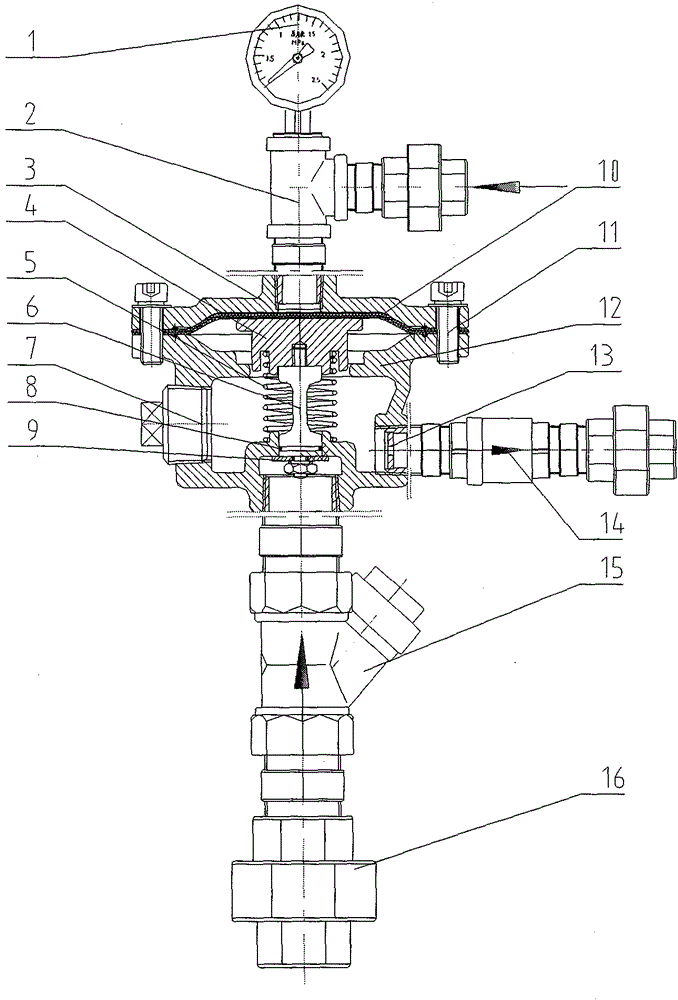

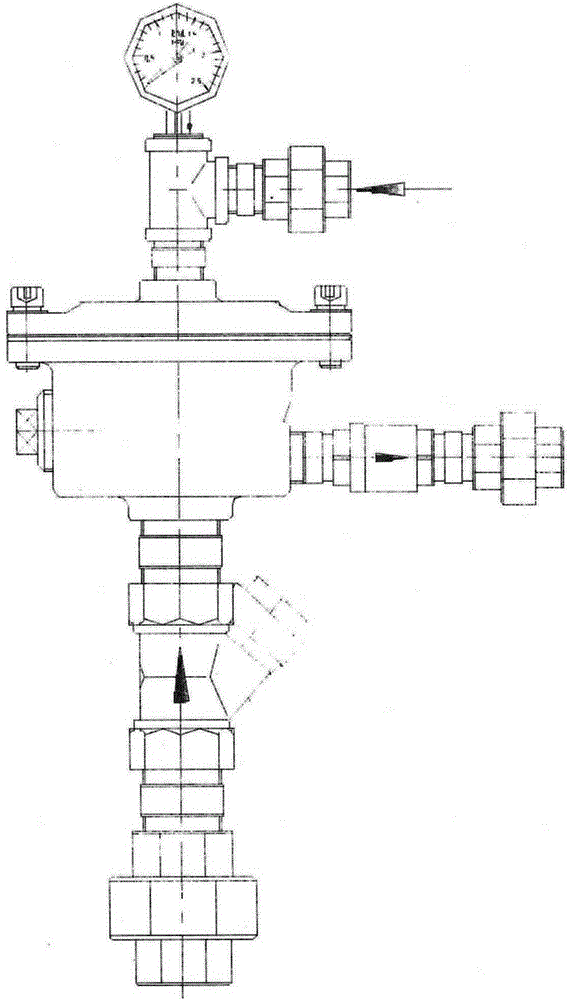

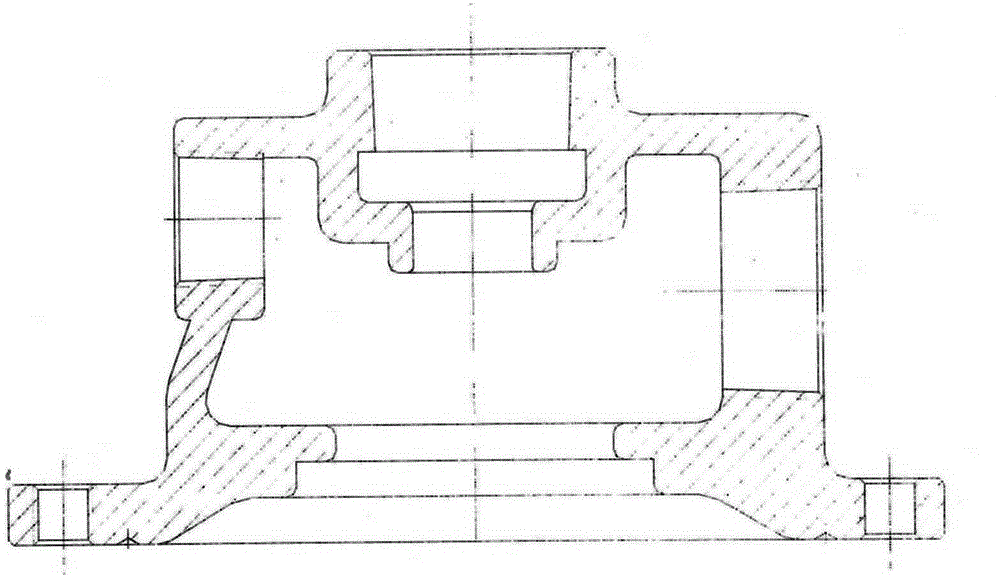

[0018] The valve body, valve cover and valve core are made of bronze alloy, and the spring and valve stem are made of 316 stainless steel. The invention is designed as a pressurized and driven piston structure. The inlet of the hydraulic foam control valve is equipped with a filter; the outlet is equipped with a mixing ratio adjustment orifice plate, Check valve; pressure gauge on the driving side of the bonnet; each interface is equipped with a cone-face linear hard-sealed joint. The O-ring seal is set in the O-ring groove at the lower part of the valve stem; the lower part of the spring is set outside the convex circle of the valve body liquid inlet, and the upper part is embedded in the valve core groove; the valve stem is tightened in the valve core, and the control diaphragm is clamped on The valve body and bonnet are locked by bolts. The inlet of the hydraulic foam control valve is equipped with a filter to avoid the impediment of impurities on the piston seal and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com