Squeezing juicer

A technology of a juicer and a cover, which is applied to the field of juicing devices, can solve the problems of low juicing efficiency, high rate of residue juice inclusion, and poor retention effect of vegetable and fruit materials, and achieves high safety and reliability in use, and overall cleaning. Low workload and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

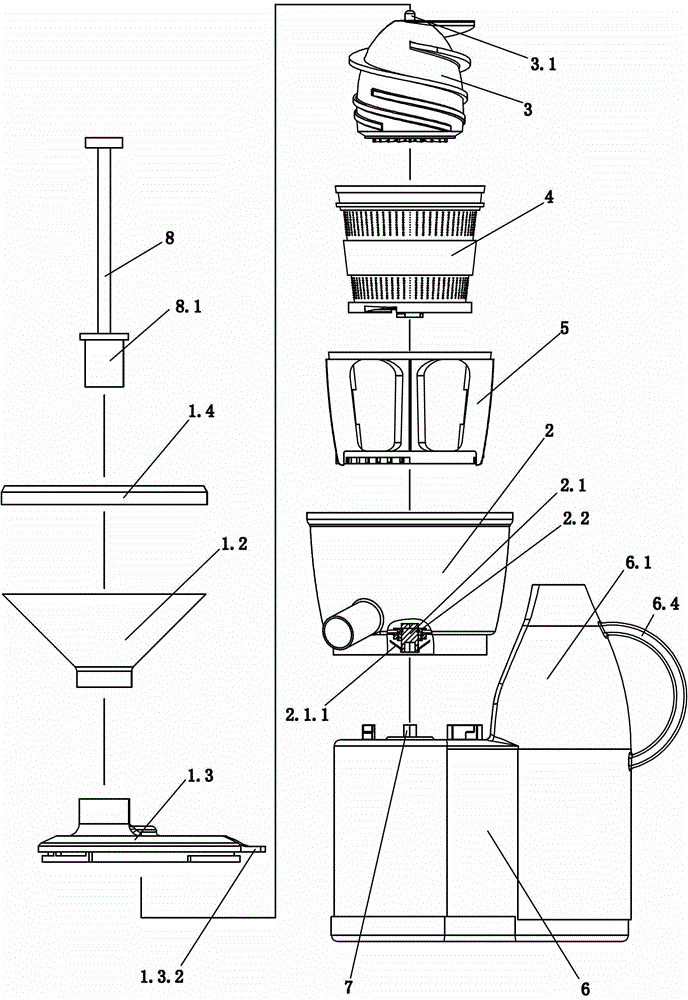

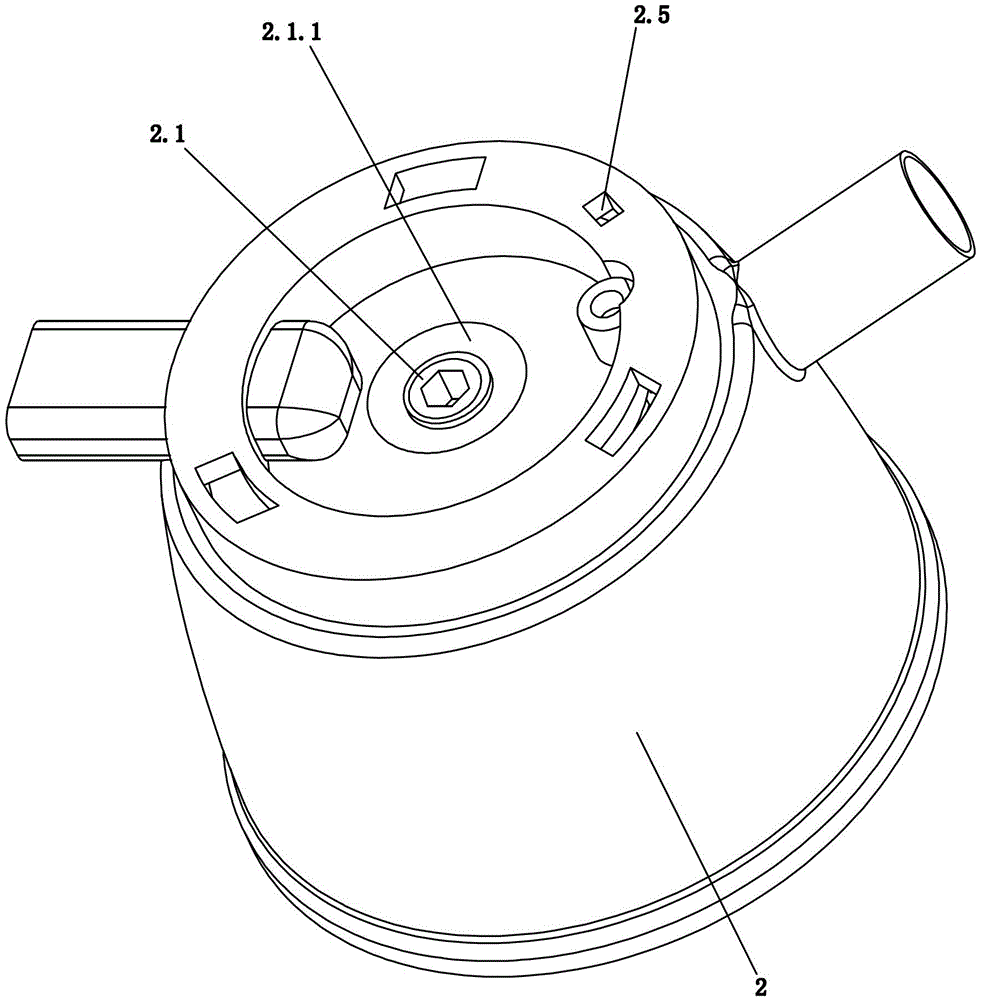

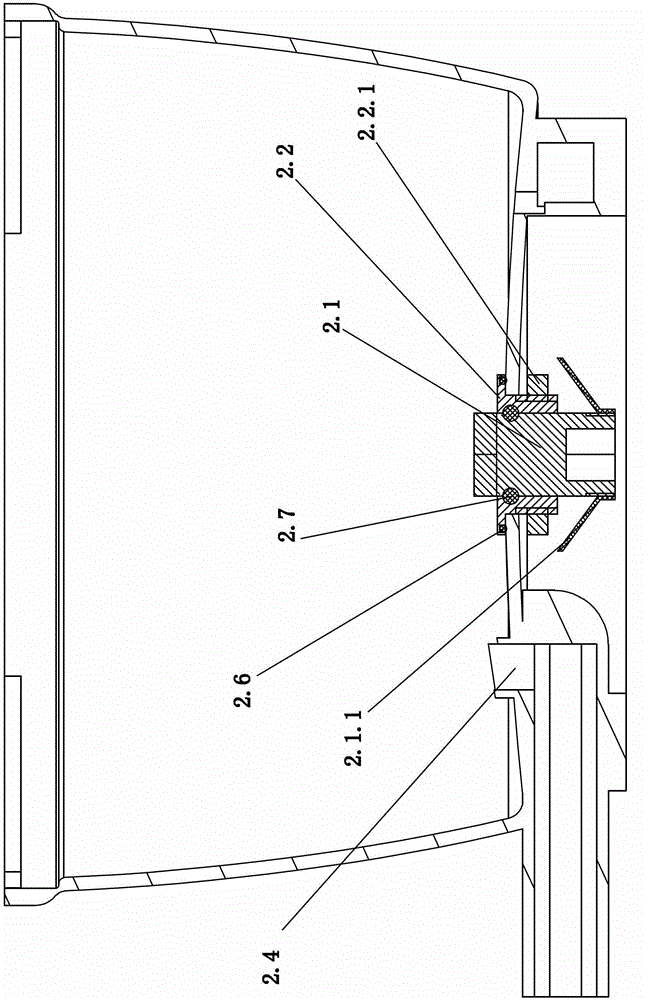

[0035] Such as figure 1 with Figure 5 As shown, the present invention includes a machine cover 1, a casing 2, a screw 3, a mesh cylinder 4, a rotating brush 5, a support 6, and a drive unit not shown in detail on the support 6. Described machine cover 1 comprises the upper end 1.2 of machine cover and the lower end 1.3 of machine cover, and the upper end 1.2 of machine cover is circular platform cylindrical structure, and its lower end extends downwards and forms the lower end connection part 1.2.1 that links to each other with the lower end 1.3 of machine cover, One side of the lower end 1.3 of the machine cover 1 is provided with a base connecting ear 1.3.2, and the other side of the lower end 1.3 of the machine cover 1 extends upwards to form an upper end connecting portion 1.3.3 communicating with the lower end connecting portion 1.2.1, and the lower end Connecting part 1.2.1 connects with connecting part 1.3.3 at the upper end to form a circular hole-shaped raw material...

Embodiment 2

[0041] The difference between the second embodiment and the first embodiment mainly lies in the difference between the structures of the screw rod 3 and the machine cover 1 . Such as Figure 7 with Figure 8As shown, the upper end 1.2 of the machine cover 1 of Embodiment 2 is a cylindrical structure, and the center of the cover 1.4 located at the upper end of the machine cover 1 is provided with an upper rotating shaft insertion hole 103, and the raw material feeding channel on the machine cover 1 1.1 is a circular channel, the axis of the raw material feeding channel 1.1 is collinear with the axis of the screw 3; the screw 3 includes a screw body, and the upper end of the screw body extends upwards to form a screw feeding part 3.2 that cooperates with the raw material feeding channel 1.1. The upper end of the feeding part 3.2 passes through the raw material feeding channel 1.1 and then extends into the upper end of the machine cover 1. The upper rotating shaft 3.1 of the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com