Instant steamed rice roll (steamed vermicelli roll) capable of being steamed in short time

A short-time, steamed technology, applied in application, food preparation, food science and other directions, can solve the problems of difficult to guarantee hygiene, difficult to preserve, easy to grow mold in rolled powder, etc., to ensure quality, not easy to mold and deteriorate, and to promote delicious food. The effect of culture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

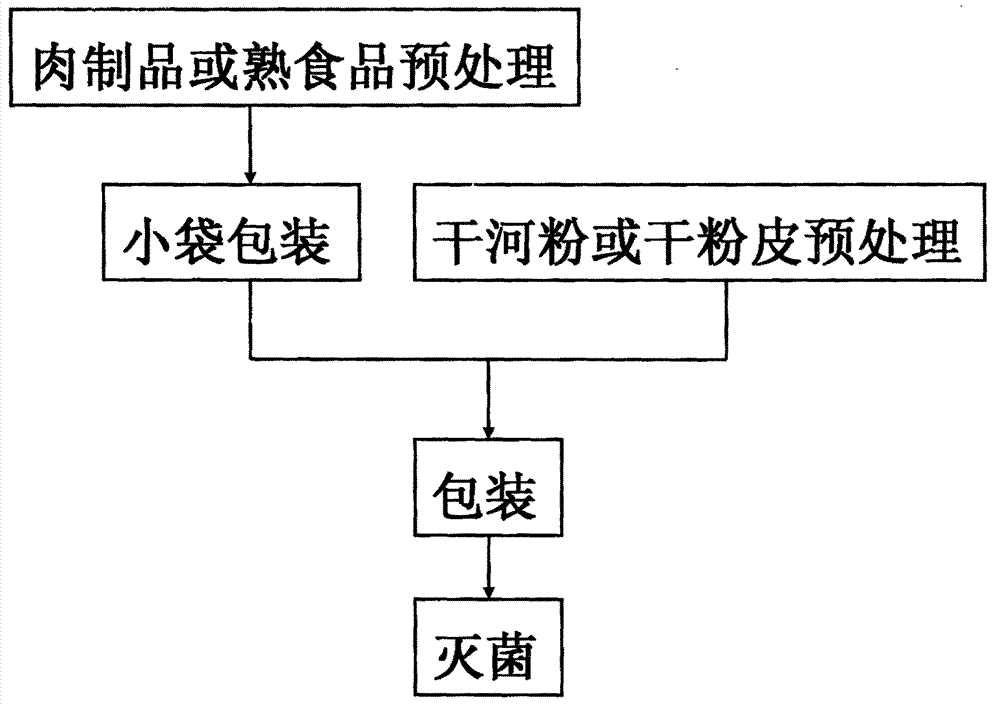

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1 step: one, make dry rice noodles: (1) material selection: select high-quality rice for use as raw material. (2) Refining and pulping: weigh the selected rice, mix with water at the ratio of 1 part of rice to 2-4 parts of water, refine the pulp, and mix evenly. (3) Steamed powder flakes: the slurry enters the steam box under the operation of the conveyor belt, and steams the powder flakes. The thickness of the powder flakes is controlled at 0.3 mm to 1.5 mm. (4) Low-temperature cooling: The powder flakes just after steaming are highly viscous and inconvenient to be removed from the package. Low-temperature cooling is required to enhance the toughness. (5) Drying of powder flakes: the steamed flakes of powder enter the dryer and are dried with hot air at 50°C-70°C. 2. Take 60g of bacon, dice the bacon, vacuum pack it into small bags after sterilization, and seal it. 3. Get 50g of dried river powder made from rice, put it into a large bag together with the s...

Embodiment 2

[0015] Embodiment 2 steps: one, make dried rice noodles: (1) material selection: select high-quality rice for use as raw material. (2) Refining and pulping: weigh the selected rice, mix with water at the ratio of 1 part of rice to 2-4 parts of water, refine the pulp, and mix evenly. (3) Steamed powder flakes: the slurry enters the steaming box under the operation of the conveyor belt, and steams the powder flakes. The thickness of the powder flakes is controlled at 0.3mm to 1.5mm. (4) Low-temperature cooling: The powder flakes just after steaming are highly viscous and inconvenient to be removed from the package. Low-temperature cooling is required to enhance the toughness. (5) Drying of powder flakes: the steamed flakes of powder enter the dryer and are dried with hot air at 50°C-70°C. 2. Take 20g of cooked food with minced meat. The cooked minced meat food is vacuum-packed into small bags after being sterilized and sealed. 3. Get 20g of dried river powder made from rice, ...

Embodiment 3

[0016] Embodiment 3 steps: one, make dry powder skin: (1) material selection: select high-quality potato starch for use as raw material. (2) Refining and blending: Weigh the selected potato starch, mix it with water according to the ratio of 1 part of potato starch to 2-4 parts of water, refine and mix evenly. (3) Steamed powder flakes: the slurry enters the steaming box under the operation of the conveyor belt, and steams the powder flakes. The thickness of the powder flakes is controlled at 0.3mm to 1.5mm. (4) Low-temperature cooling: The powder flakes just after steaming are highly viscous and inconvenient to be removed from the package. Low-temperature cooling is required to enhance the toughness. (5) Drying of powder flakes: the steamed flakes of powder enter the dryer and are dried with hot air at 50°C-70°C. 2. Take 100g of minced meat cooked food. After sterilization, it is vacuum-packed and packed into small bags, and sealed. 3. Take 100g of dried potato powder skin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com