Carton former, inspection device, and print register control method for carton former

A control unit and equipment technology, applied in the direction of printing, printing machines, rotary printing machines, etc., can solve the problem of not being able to prevent the production of defective items, and achieve the effects of simplifying equipment design, facilitating pre-adjustment, and reducing burdens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

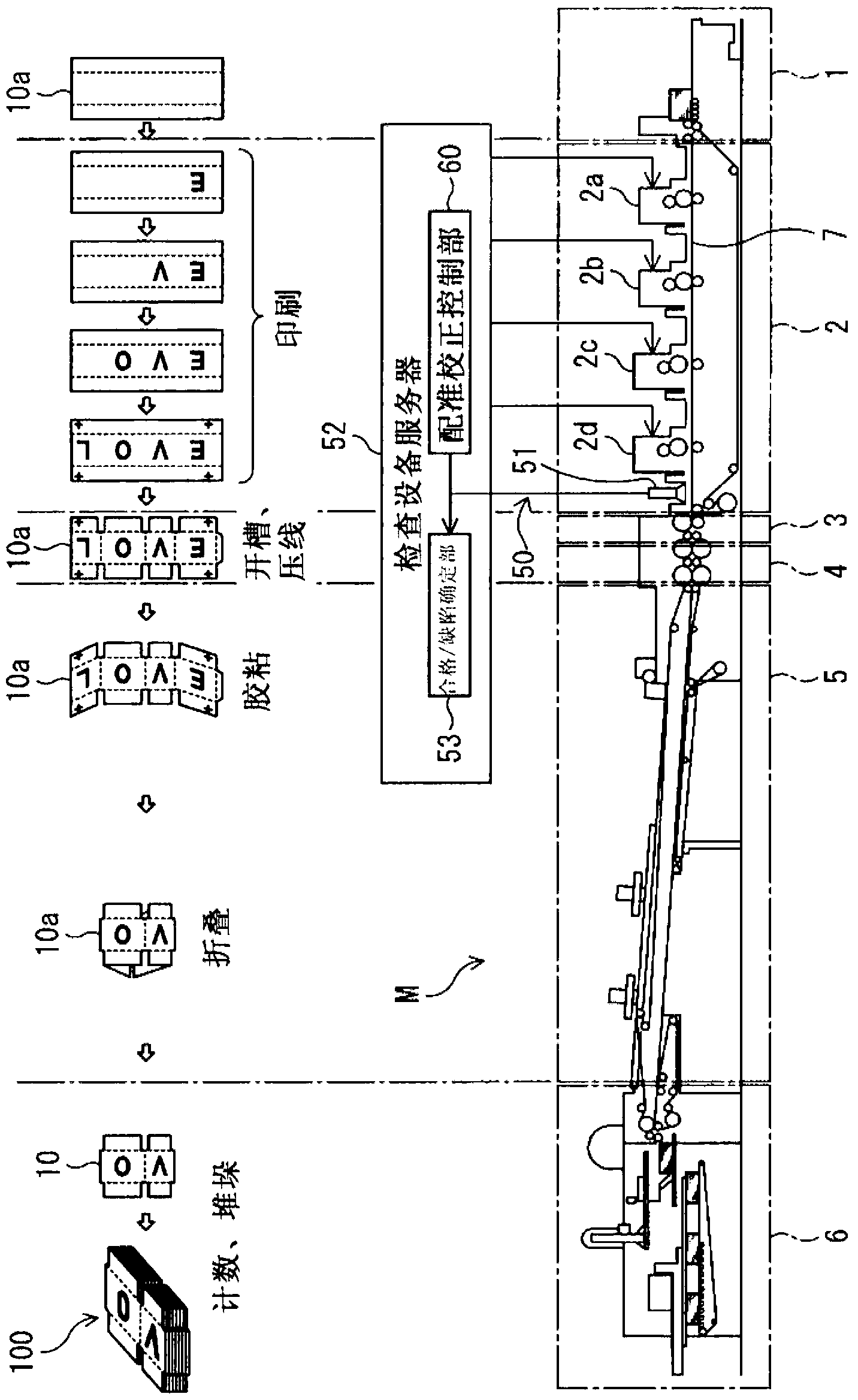

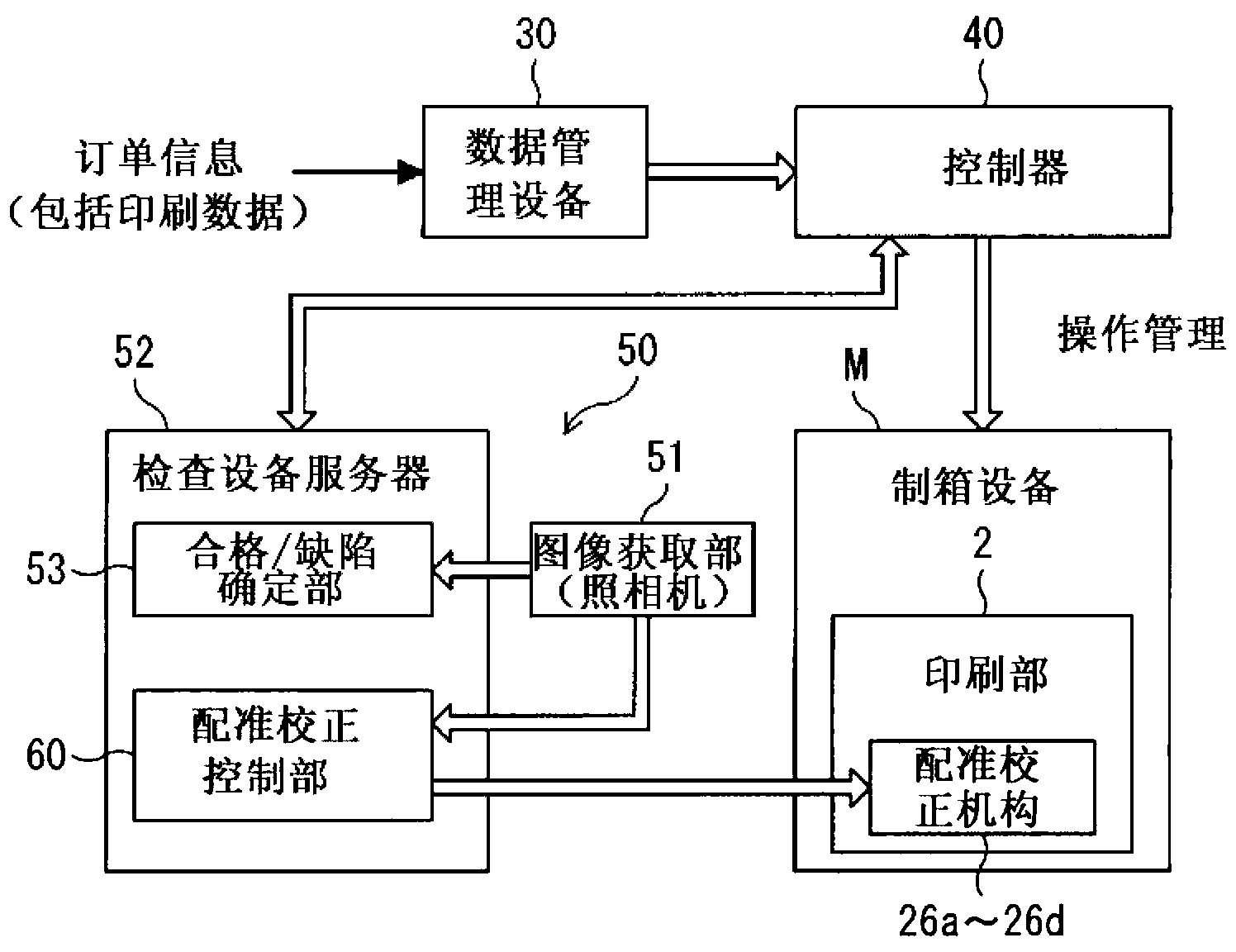

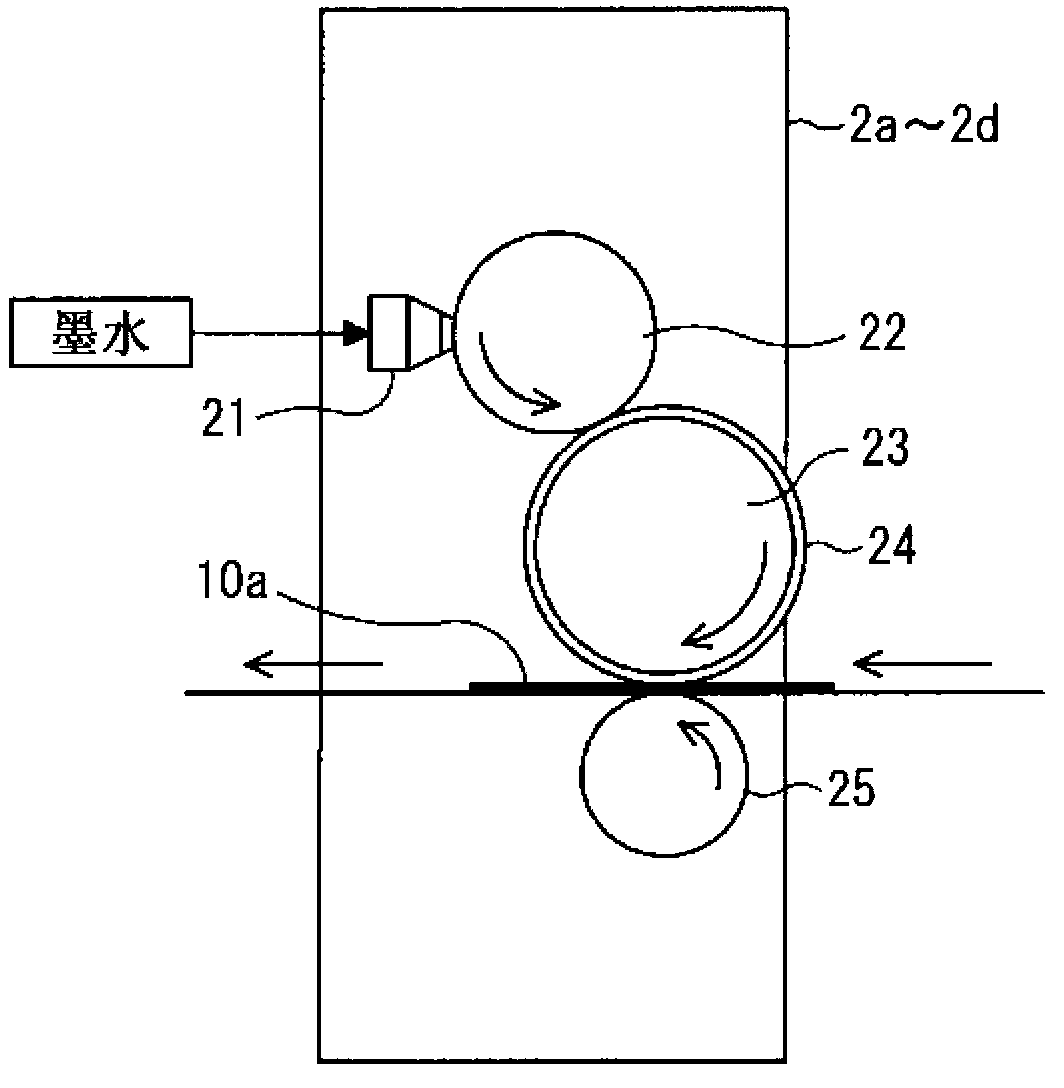

[0056] Figure 1 to 9 It is a diagram illustrating a box-making apparatus according to the first embodiment of the present invention, an inspection unit provided in the box-making apparatus, and a registration correction method used therefor. Description will be given with reference to the drawings.

[0057] (Box-making equipment)

[0058] First, the box making apparatus according to this embodiment will be described. figure 1 It is a configuration diagram illustrating the box making equipment according to this embodiment. in figure 1 In the bottom part of the drawing, the equipment configuration is illustrated, and separately from the equipment configuration, the upper part of the drawing illustrates the steps in which the corrugated cardboard sheet as the box sheet The material is processed into a flat folding box (box-making sheet).

[0059] Such as figure 1 As shown in, from the upstream side to the downstream side, the box making equipment M is provided with a paper feeding s...

no. 2 example

[0096] Next, refer to Picture 10 The second embodiment of the present invention is explained.

[0097] Such as Picture 10 As shown in the first embodiment, this embodiment uses an inspection unit that determines whether the produced box is qualified or defective. However, with the exception of the camera 51 and the pass / defect determination unit 53 which determines whether the printing performed by the printing unit 2 is pass or defective (whether the printing position is pass or defective, or whether any color is missing), according to this embodiment The inspection unit of the example includes: a sensor (notching position detection device) 54 that detects the position of the notch by the cutting machine; a pass / defect determination unit 55 that passes the detected notch The position is compared with the sample notching position to determine whether the notching position is qualified or defective; a sensor (cutting position detection device) 56 that detects the cutting positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com