Liquid crystal display device and manufacturing method

A technology of a liquid crystal display device and a manufacturing method, which is applied in the directions of nonlinear optics, instruments, optics, etc., can solve the problems that the width of the sealing frame cannot be reduced, and the reliability is greatly affected, so as to reduce the size of the frame, ensure reliability, and suppress overlapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example )

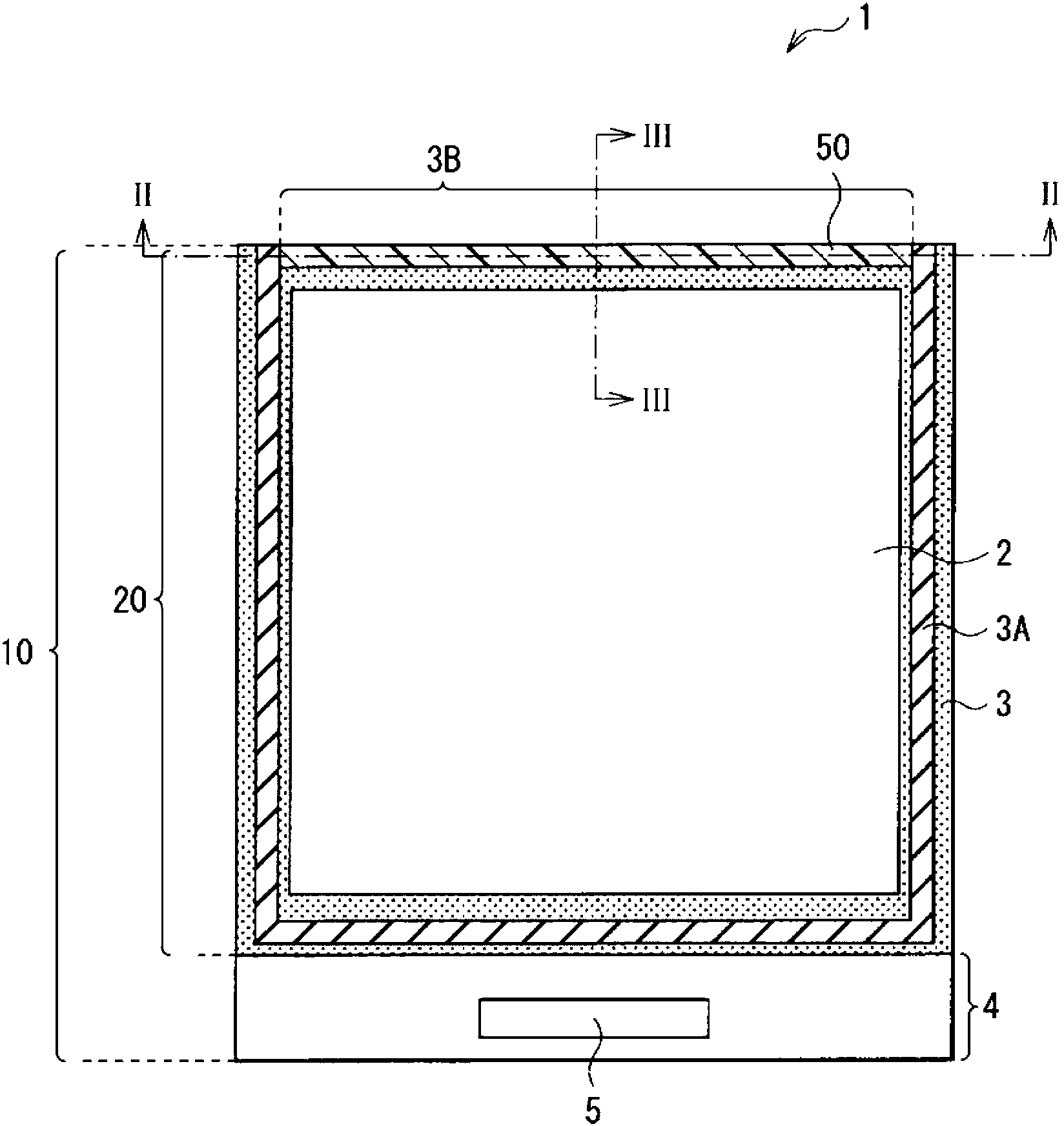

[0061] figure 1 The overall configuration of the liquid crystal display device according to the first embodiment of the present invention is shown. This liquid crystal display device 1 is used, for example, in a mobile phone or a smartphone. The liquid crystal display device 1 has a display portion 2 and a frame portion 3 around the display portion 2 .

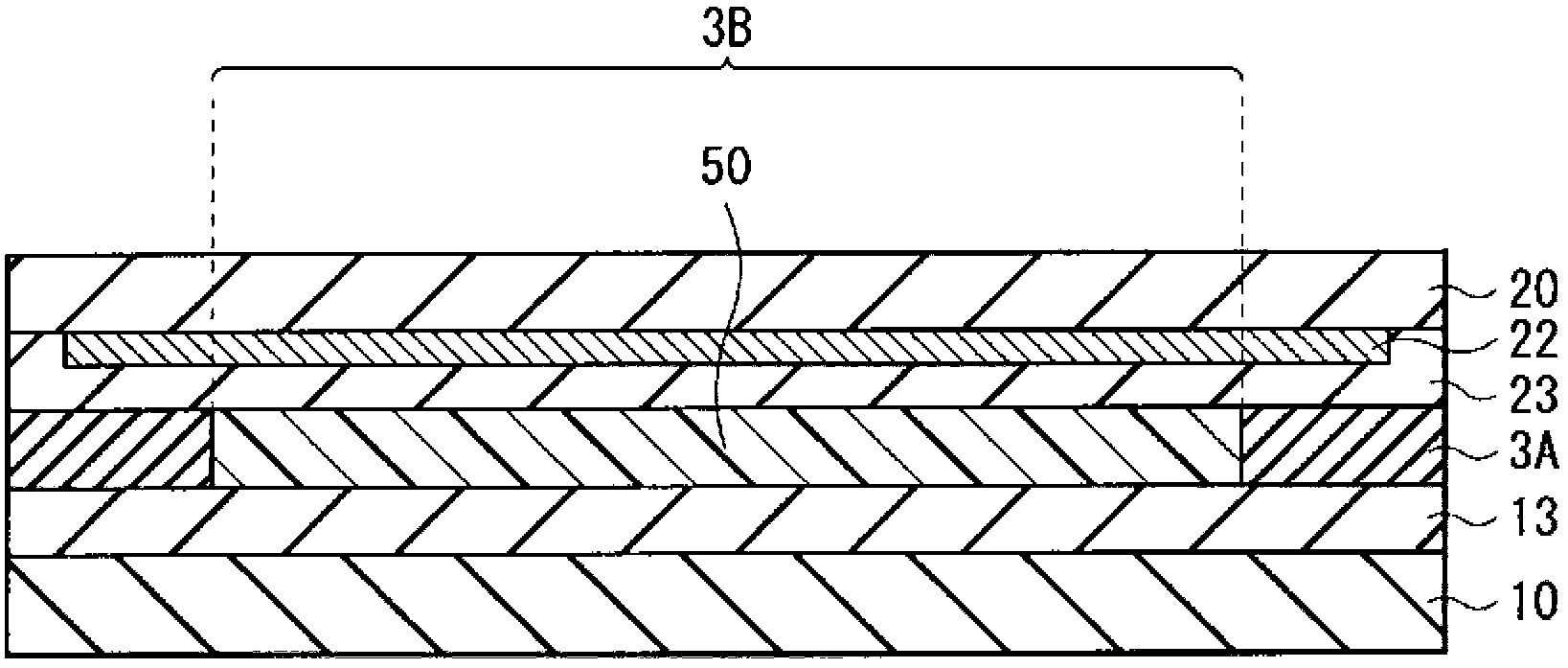

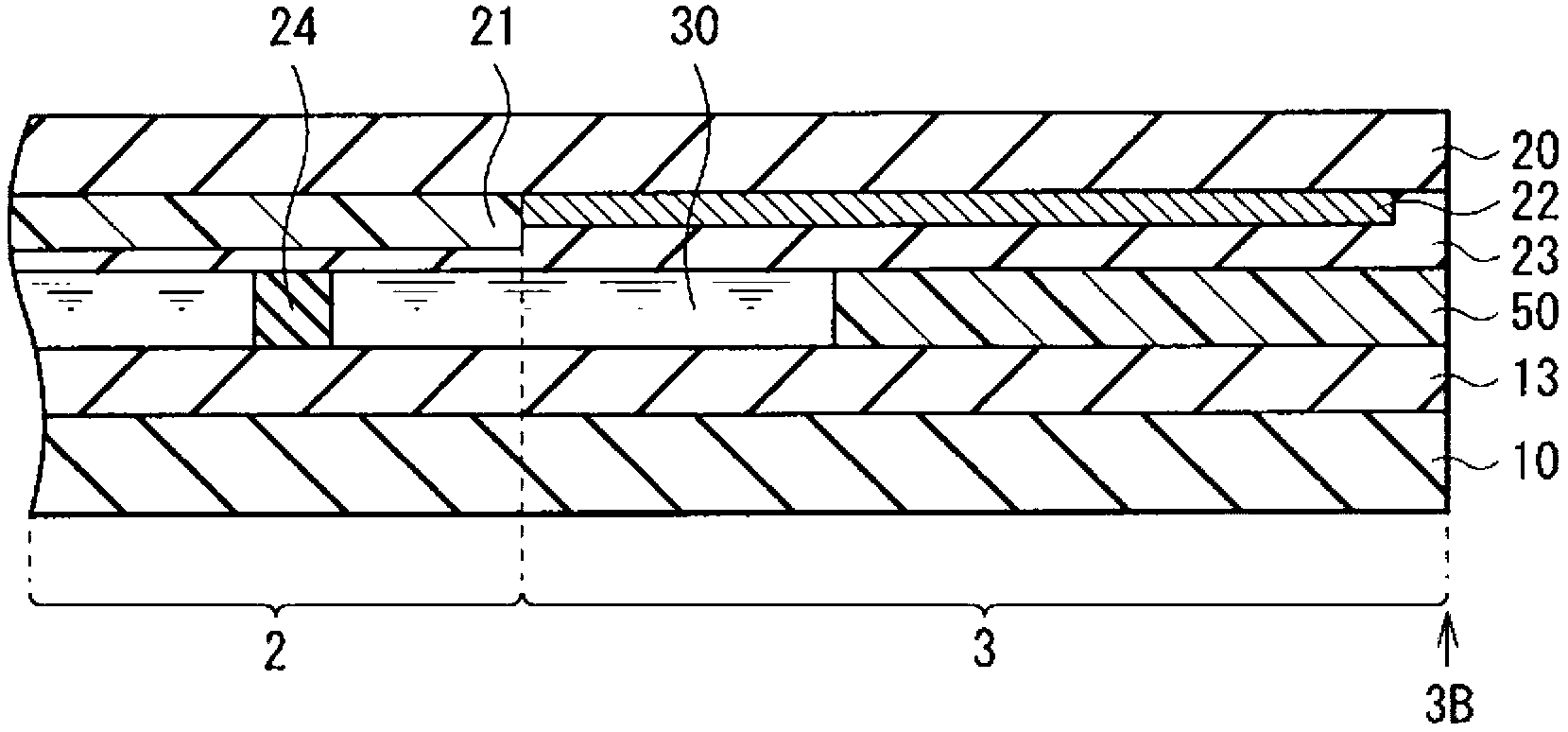

[0062] The display section 2 has a liquid crystal layer 30 ( figure 1 not shown, see image 3 ), the paired substrates (the first substrate 10 and the second substrate 20 ) are made of glass, for example. In the display section 2, a plurality of pixels (not shown) formed of liquid crystal display elements are arranged in a matrix.

[0063] The frame portion 3 is a frame-like area surrounding the display portion 2 at peripheral portions of the first substrate 10 and the second substrate 20 . In the frame portion 3 , a seal frame 3A is mainly composed of thermosetting resin, for example, and is provided to surround the disp...

no. 2 example )

[0083] Image 6 A plan configuration of a liquid crystal display device 1A according to a second embodiment of the present invention is shown. Figure 7 shows along the Image 6 The cross-sectional structure of the VII-VII line, while Figure 8 shows along the Image 6 The cross-sectional structure of the VIII-VIII line. In the present embodiment, the flow of the sealing material 50 is controlled by providing the overflow structure 40 between the inlet 3B and the display portion 2 . Other than that, this liquid crystal display device 1A has the same configuration, operation and effects as those of the first embodiment.

[0084] The overflow structure 40 has, for example, a planar shape with three sides forming a rectangle, and is formed along one side of the display portion 2 (in Image 6 The upper side of the middle) is composed of a straight part and a curved part at both ends of the straight part. The gap 41 is made between the curved portions at both ends of the over...

example 1)

[0104] Figure 12 A plan configuration of a liquid crystal display device 1B according to Modification Example 1 is shown. This liquid crystal display device 1B has the same construction, operation and effect as the second embodiment except that the overflow structure 40 is provided in a straight line along the upper side of the display portion 2, and can be manufactured similarly to the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com