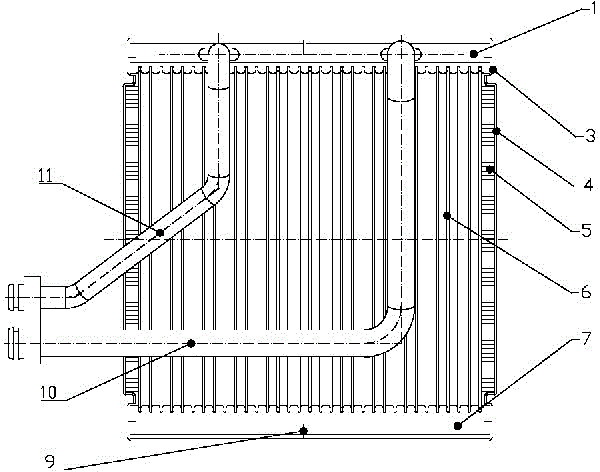

Double-layer parallel flow evaporator

A parallel flow, evaporator technology, used in evaporators/condensers, refrigeration components, refrigerators, etc., can solve the problems of reduced refrigeration capacity, unfavorable refrigeration oil circulation, and large refrigerant flow resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

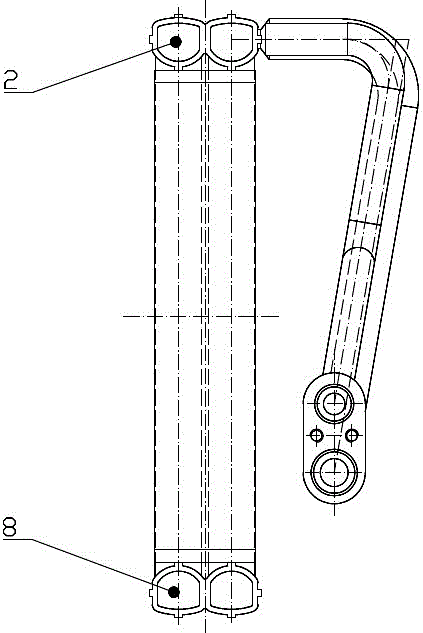

[0015] The present invention is described in detail below in conjunction with accompanying drawing:

[0016] The double-layer parallel flow evaporator includes two groups of cooling cores arranged one above the other next to each other. The upper cooling core consists of the first liquid collecting pipe 1, the second liquid collecting pipe 7, and The plurality of flat pipes 6 between the second liquid collection pipe 7 are formed, and the lower cooling core is composed of the third liquid collection pipe 2, the fourth liquid collection pipe 8, and the connection between the third liquid collection pipe 2 and the fourth collection pipe. A plurality of flat pipes 6 between the liquid pipes 8 constitute. The first liquid collection pipe 1 is arranged adjacent to the third liquid collection pipe 2, the second liquid collection pipe 7 is arranged adjacent to the fourth liquid collection pipe 8, the first liquid collection pipe 1, the second liquid collection pipe 7, and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com