Construction method for prefabricating mortar filled polyvinyl chloride (PVC) tube as inner support for beam side dies

A technology of PVC pipe and construction method, which is applied to the preparation of building components on site, the connectors of formwork/formwork/work frame, construction, etc., which can solve the problems of insufficient protective layer of steel bars, etc., and achieve control of forming and appearance quality, The effect of reducing quality problems and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

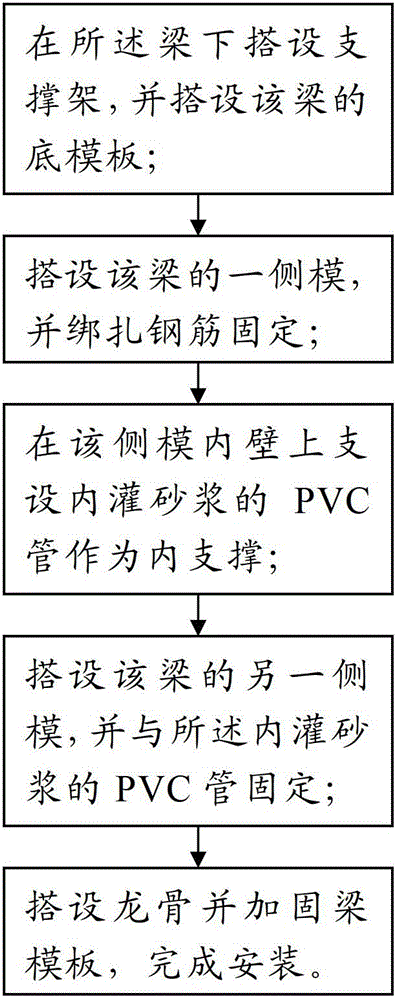

[0016] Cooperate with reference figure 2 Shown, be the flow chart of the present invention's prefabricated inner mortar PVC pipe used as the internal support construction method of the beam side form, comprising the following steps:

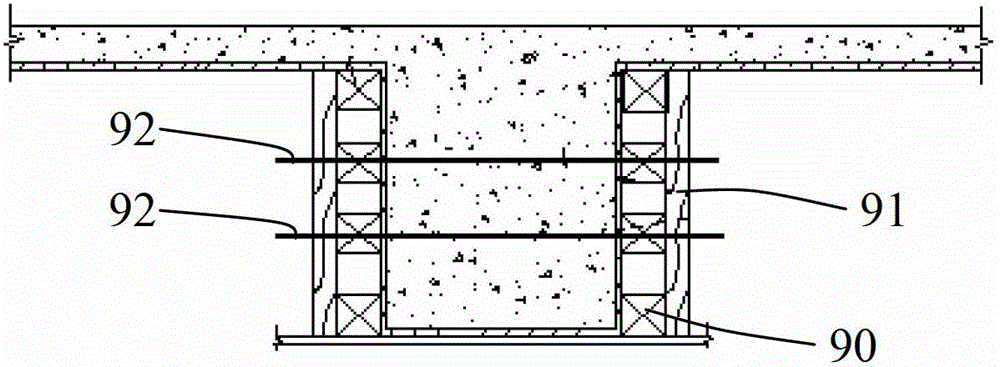

[0017] 1) Set up a support frame under the beam, and set up the bottom template of the beam;

[0018] 2) Set up the formwork on one side of the beam and fix it with steel bars;

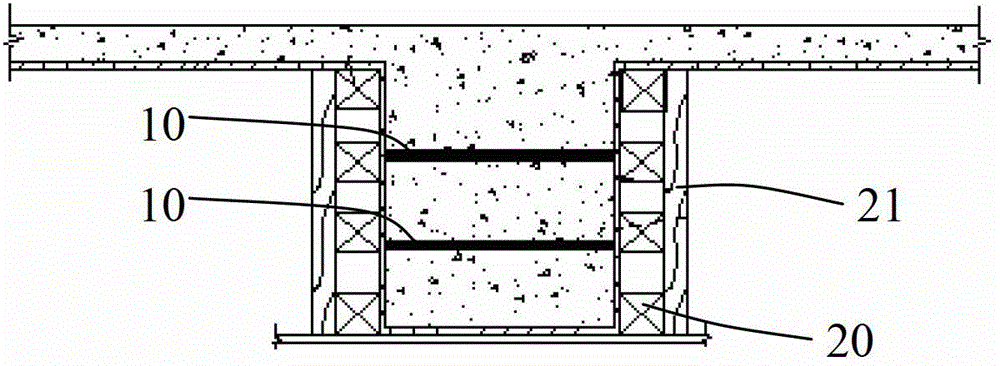

[0019] 3) Cooperate with reference image 3 As shown, a PVC pipe 10 filled with mortar is supported on the inner wall of the side form as an inner support, and the side forms on both sides are tightened against the PVC pipe 10 filled with mortar through pull bolts or clamps to form a stable system . Among them, the inner keel of the template is 20, and the outer keel is 21;

[0020] 4) Set up the other side form of the beam and fix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com