Method for extracting pigment from tangerine peel

A technology of orange peel and pigment, which is applied in the field of preparation technology for extracting pigment and essential oil from orange peel, can solve the problems of large solvent loss, low oil yield, unsuitability for large-scale industrial production, etc., and achieve the effect of increasing the output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for extracting essential oil and pigment from orange peel, comprising the following steps:

[0024] 1) Select fresh orange peels without mildew, and put them in a cool, ventilated and dry place for later use;

[0025] 2) Soak 100 g of the orange peel in step 1) in 1 L of calcium carbonate saturated aqueous solution for 24 hours, remove and rinse;

[0026] 3) Cut the orange peel into 5mm square pieces, soak in 70% ethanol for 30 minutes, and remove the ethanol by rotary evaporation under reduced pressure;

[0027] 4) Irradiate under ultraviolet light for 15 minutes, send it into a screw press, add 100ml of pH regulator when pressing, the components of pH regulator are: 0.2mol / L NaCl and 0.1mol / L NaHCO 3 ;

[0028] 5) Take the filtrate after filtering the extruded product, and take out the filter residue for the subsequent production process of other products; according to the volume ratio of filtrate: sodium sulfate solution, add a sodium sulfate solution with...

Embodiment 2

[0037] A method for extracting essential oil and pigment from orange peel, comprising the following steps:

[0038] 1) Select fresh orange peels without mildew, and put them in a cool, ventilated and dry place for later use;

[0039] 2) Soak 100 g of the orange peel in step 1) in 1 L of calcium carbonate saturated aqueous solution for 24 hours, remove and rinse;

[0040] 3) Cut the orange peel into 5mm square pieces, soak in 70% ethanol for 40 minutes, and remove the ethanol by rotary evaporation under reduced pressure;

[0041] 4 Irradiate under ultraviolet light for 30 minutes, send it into the screw press, add 100ml of pH regulator when pressing, the components of the pH regulator are: 0.2mol / L NaCl and 0.1mol / L NaHCO 3 ;

[0042] 5) Take the filtrate after filtering the extruded product, and take out the filter residue for the subsequent production process of other products; according to the volume ratio of filtrate: sodium sulfate solution, add a sodium sulfate solution w...

Embodiment 3

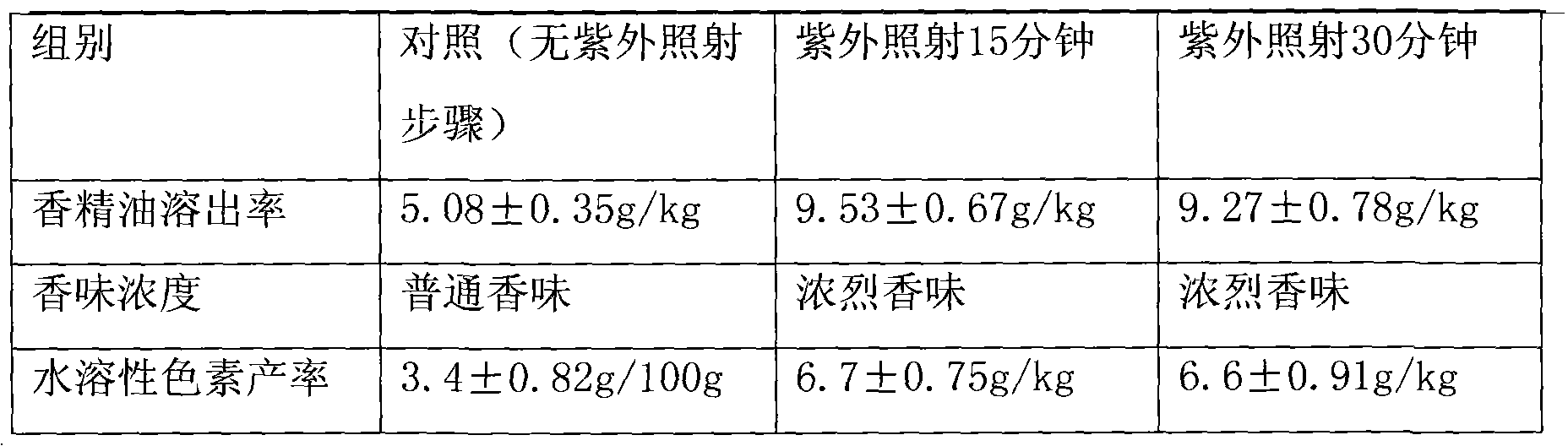

[0051] 1. Analysis of essential oils and pigment components extracted by embodiment 1:

[0052] The components of essential oils were analyzed by GC-MS technology: D-limonene 81.17%, terpinene 6.27%, myrcene 2.96%, linalool 2.46%, 2-thujene 1.28%, terpinolene 1.046%, and other minor components. At room temperature, use an ultraviolet-visible spectrometer to analyze the visible spectrum in the range of 400-800nm, use absolute ethanol as a reference, take the wavelength as the abscissa, and the absorbance as the ordinate to plot the absorption curve, and the oil solubility is between 440nm and 468nm There are two obvious absorption peaks at 475nm, and the water solubility has a significantly larger absorption peak at 475nm. After weighing, it was found that the yield of water-soluble pigment was about 0.6g / 100g orange peel; the yield of oil-soluble pigment was about 0.3g / 100g orange peel.

[0053] 2. Appropriate amount of ethanol treatment:

[0054] Using an appropriate amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com