Intelligent stirring concrete pump

A concrete pump, intelligent technology, applied in cement mixing device, clay preparation device, mixing operation control and other directions, can solve the problems of reducing operators, poor continuity, proficiency and technical level efficiency, etc., to improve efficiency, The effect of reducing personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

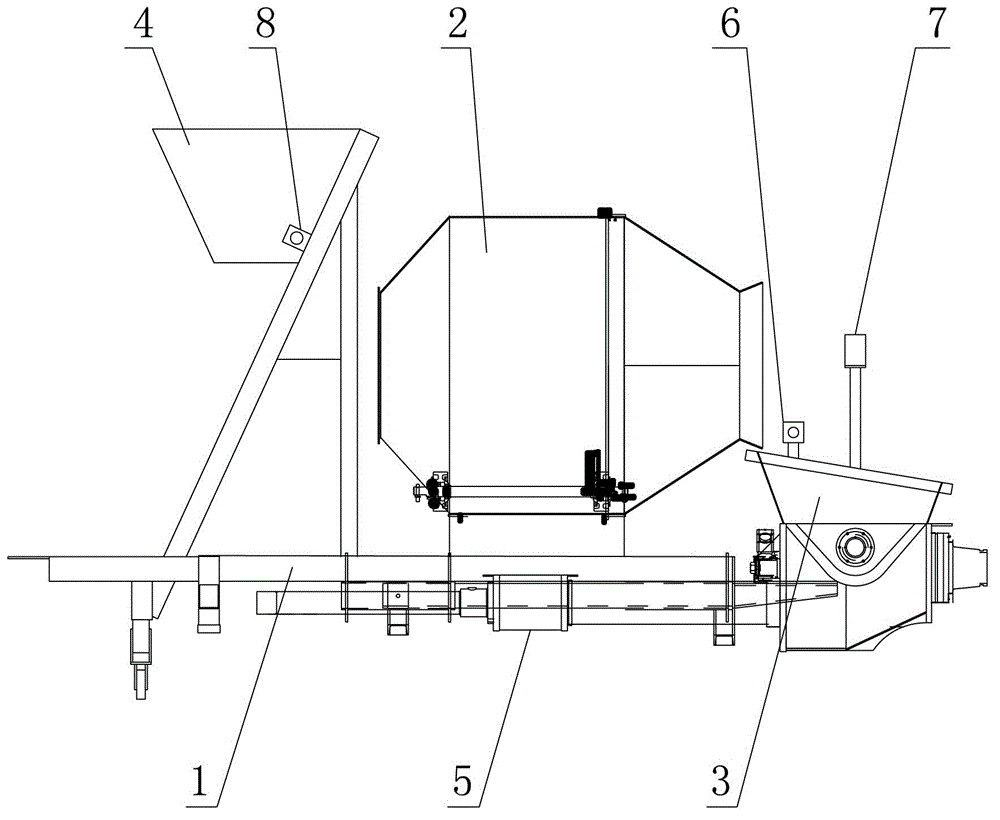

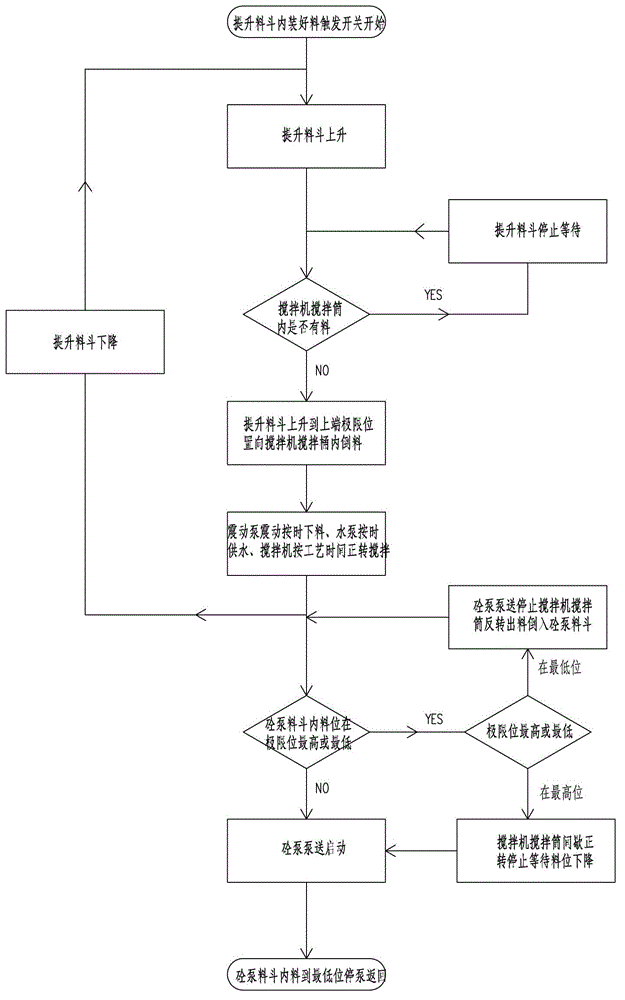

[0024] Such as figure 1 The shown intelligent mixing concrete pump includes a frame 1, a mixer 2 installed on the top of the frame 1, a concrete pump hopper 3 installed at the front of the mixer 2, a feeding device 4 installed at the rear of the mixer 2, an installation The pumping mechanism 5 at the bottom of the frame 1, the power mechanism for driving each mechanism, the PLC control system, the display status and control switch, and the touch screen for changing process parameters.

[0025] The discharge port of the mixer 2 is provided with a first material sensor 6 for detecting whether there is material released from the mixer 1; the inside or upper part of the concrete pump hopper 3 is provided with a second material sensor 7 for detecting the material level in the concrete pump hopper 3 . The height of the material level in the concrete pump hopper 3 is properly controlled between the allowable highest level and the lowest level. If it is too high, the material in...

Embodiment 2

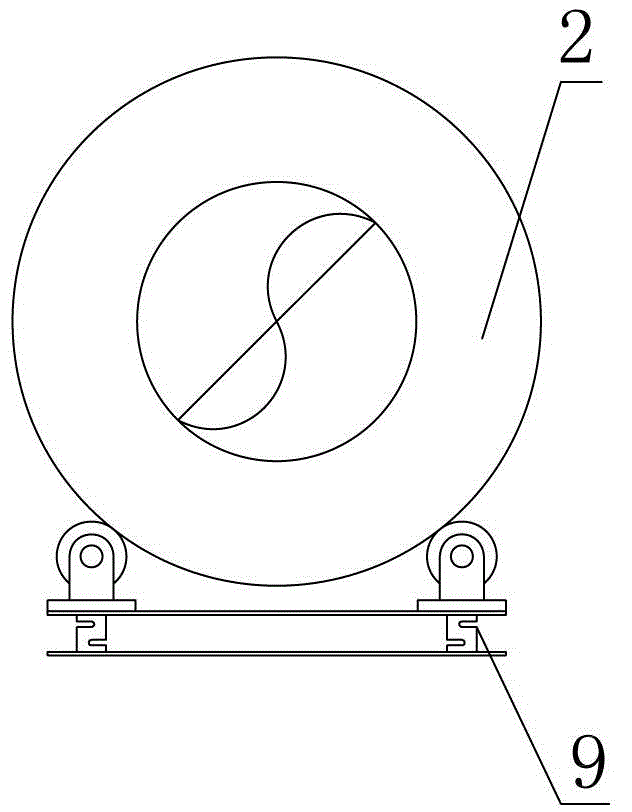

[0031] This embodiment is basically the same as Embodiment 1, the difference is: as image 3 As shown: the lower part of the mixer 2 is provided with a weighing sensor 9, which senses whether there is material through the weight change.

Embodiment 3

[0033] This embodiment is basically the same as the above-mentioned embodiment, the difference is: as Figure 4 Shown: Blender 2 is a forced blender. The first material sensor 6 is to detect whether there is material on the flow channel when the discharge door of the forced mixer is opened, as a criterion for judging whether there is material in the mixing drum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com