Additive composition for metal sintering

A technology for metal sintering and alkali metal compounds, which is applied in the field of metal sintering compositions, can solve problems such as excessive heat, ore quality decline, and sinter strength reduction, and achieves the effects of improving sintering yield and saving heat sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

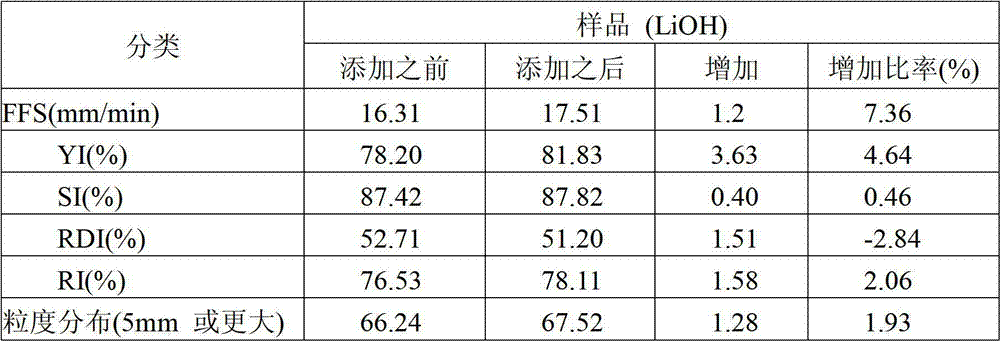

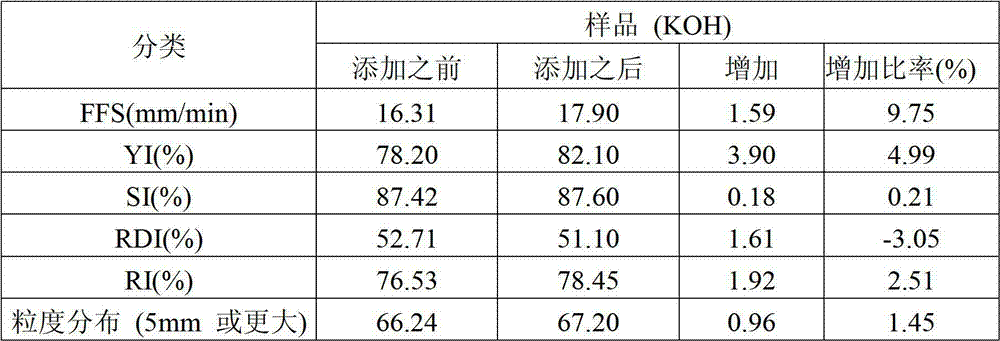

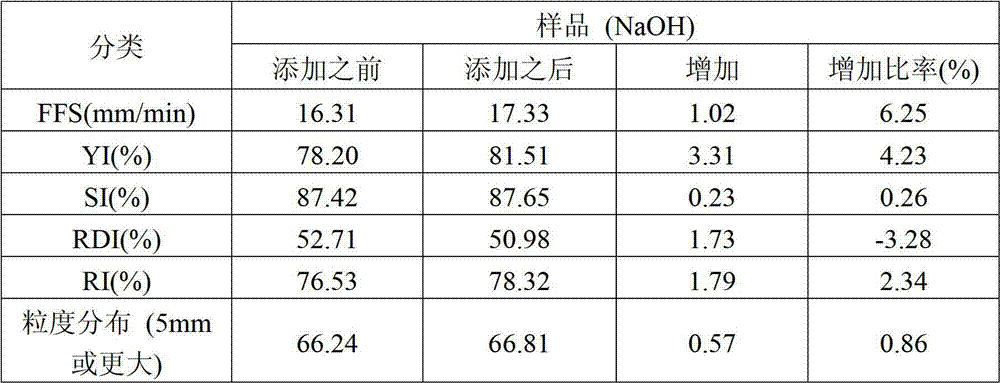

[0028] The first embodiment: calcium carbonate (CaCO 3)+alkali metal compound (lithium, potassium or sodium, etc.)

[0029] First, according to one embodiment of the additive composition for metal sintering, one comprising calcium carbonate (CaCO 3 ) and an alkali metal compound as an additive for sintering.

[0030] Calcium carbonate and alkali metal compounds are melting accelerators that lower the melting point in sintered iron ore and facilitate chemical reactions during iron ore sintering using heat sources such as coal, coke, coal or coke powder or the like. In more detail, calcium carbonate is strong in the catalytic performance of causing a chemical reaction by burning a heat source and increasing the rate of a chemical reaction without significantly affecting the heat of reaction, and alkali metal compounds have high basicity, which can accelerate a heat source by chemical reaction Combustion increases the heat of reaction.

[0031] The calcium carbonate may utiliz...

no. 2 approach

[0083] Second embodiment: calcium carbonate+alkali metal compound+magnesium compound

[0084] According to a second embodiment, the composition comprises, in addition to an alkali metal compound and calcium carbonate, a magnesium compound, said additive being used for sintering. That is, a magnesium compound is additionally added to the alkali metal compound to promote the formation of calcium ferrite and magnesium ferrite for bonding between iron ore particles.

[0085] When said alkali metal compound is used in excess, it impairs the density of sintered ore, resulting in less strength increase, so magnesium compound is used to supplement said alkali metal compound.

[0086] Described magnesium compound comprises at least one selected from magnesium oxide (MgO), magnesium carbonate (MgCO 3 ), magnesium bicarbonate (Mg(HCO 3 ) 2 ), magnesium hydroxide (Mg(OH) 2 ), magnesium peroxide (MgO 2 ), magnesium nitrate (Mg(NO 3 ) 2 ) compounds.

[0087] As mentioned above, wher...

no. 3 approach

[0122] The third embodiment: calcium carbonate + alkali metal compound + manganese compound

[0123] According to a third embodiment, the composition comprises, in addition to the sintering additives calcium carbonate and alkali metal compounds, a manganese compound. That is, in order to improve the efficiency of the sintering process, a manganese compound having a higher melting point than the alkali metal compound is added.

[0124] The manganese compound includes at least one selected from manganese dioxide (MnO 2 ), manganese carbonate (MnCO 3 ), manganese oxide (MnO), manganese trioxide (MnO 3 ), manganese trioxide (Mn 2 o 3 ), trimanganese tetraoxide (Mn 3 o 4 ), manganese nitrate (Mn(NO 3 ) 2 ) and potassium permanganate (KMnO 4 ) compounds.

[0125] The effects of the various manganese compound additive groups will now be described in conjunction with the following Tables 23-26, which show the measured results for each group of experimental examples. In this c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com