High-performance rectifier diode replaced circuit

A technology of rectifier diodes and alternative circuits, applied in electrical components, conversion equipment without intermediate conversion to AC, conversion of AC power input to DC power output, etc., can solve the problem of reducing power utilization efficiency, high forward voltage drop, and high energy consumption. and other problems, to achieve good application prospects, low forward voltage drop, and low self-power loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

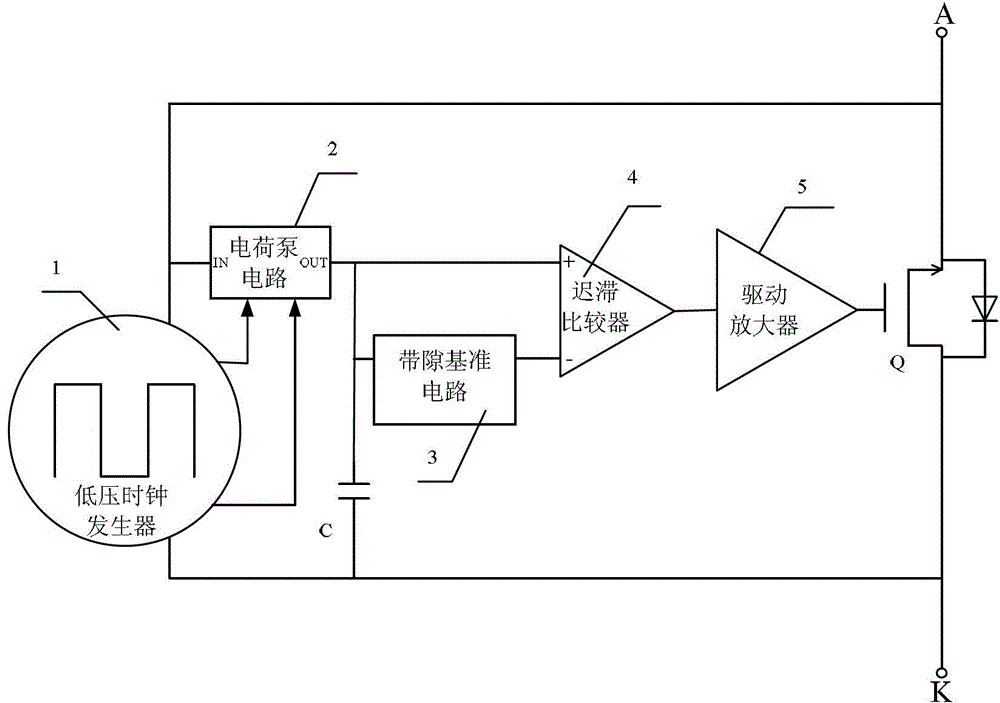

[0018] see figure 1 , figure 2 , a rectifier diode replacement circuit, including a capacitor C, a low-voltage clock generator 1, a charge pump circuit 2, a bandgap reference circuit 3, a hysteresis comparator 4, a drive amplifier 5 and a power MOS tube Q, wherein:

[0019] The low-voltage clock generator 1 detects the voltage between the drain and the source of the power MOS transistor Q, and generates a clock signal to drive the charge pump circuit 2;

[0020] The charge pump circuit 2 detects the voltage between the drain and the source of the power MOS transistor Q and stores the charge in the capacitor C after amplifying it;

[0021] The voltage stored on the capacitor C and the reference voltage output by the bandgap reference circuit 3 are respectively output to the hysteresis comparator 4 for comparison; when the voltage stored on the capacitor C is greater than the reference voltage output by the bandgap reference circuit 3, the hysteresis comparator 4 outputs Turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com