Device and method for preparing metal needle point

A needle-point, metal technology, applied in the field of scanning probe microscopy, can solve problems such as difficulty and high repetition, and achieve the effects of stable process, high success rate and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The specific implementation of the device and method for preparing metal needle tips provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

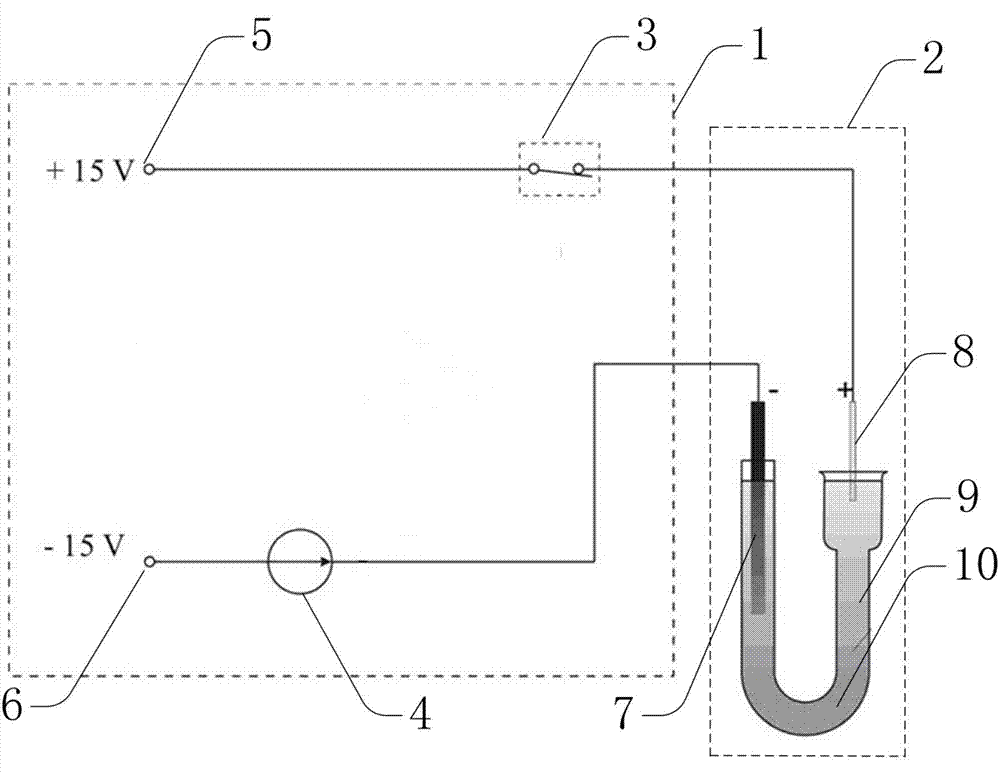

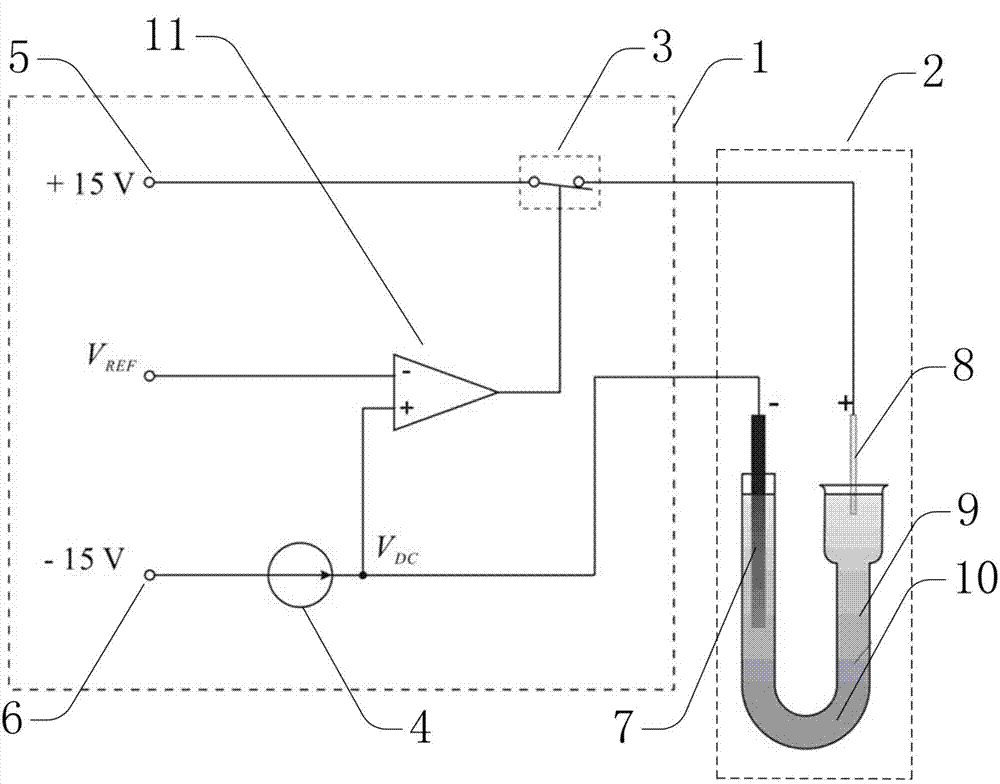

[0026] attached figure 1 Shown is a schematic structural view of the device for preparing metal needlepoints according to the first embodiment of the present invention. See attached figure 1 , in this embodiment, the device for preparing a metal needle tip includes a control circuit 1 and an electrochemical cell 2 .

[0027] The control circuit 1 includes a power supply, a switch 3 and a constant current source 4 . The power supply provides electric energy for the device. In this embodiment, the positive pole of the power supply is a positive DC source 5 with a potential of +15V, and the negative pole of the power supply is a negative DC source 6 with a potential of -15V. The switch 3 is set at any position in the control circuit 1 to control the opening and closing of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com