Method and device for detecting optical fiber ring quality based on optical coherence tomography

A technology of optical coherence tomography and scanning technology, which is applied in the field of optical fiber wrapping and detection, can solve the problems of unable to find the optical fiber loop, long winding cycle, difficult to ensure quality, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

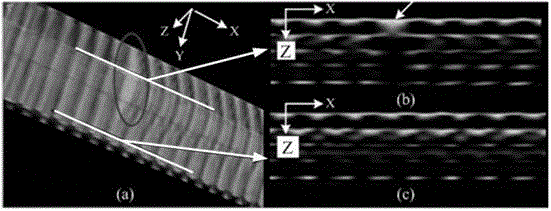

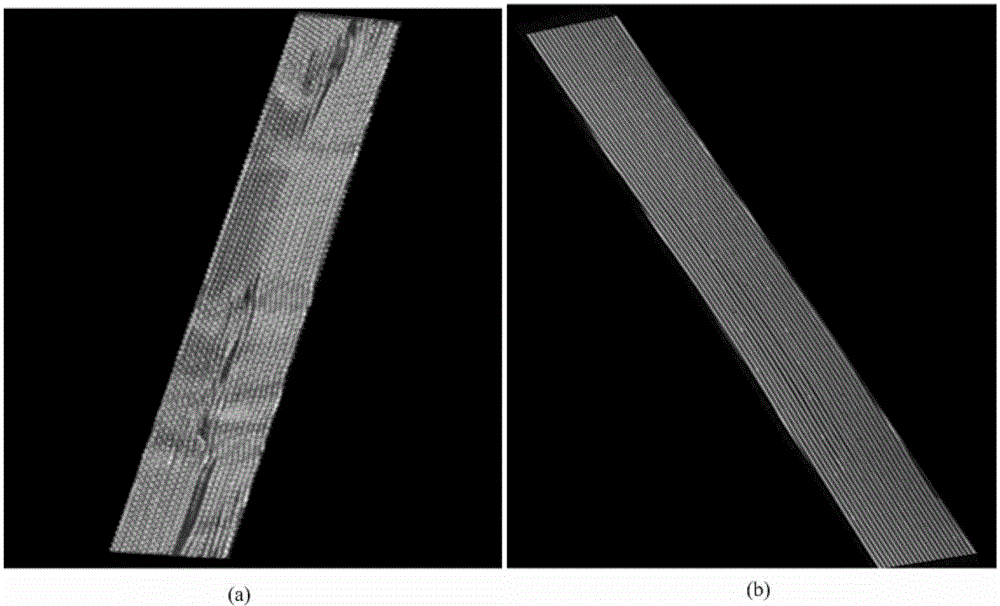

[0041] A method and device for detecting the quality of an optical fiber ring based on optical coherence tomography technology proposed by the present invention are described in detail in conjunction with the accompanying drawings and embodiments as follows:

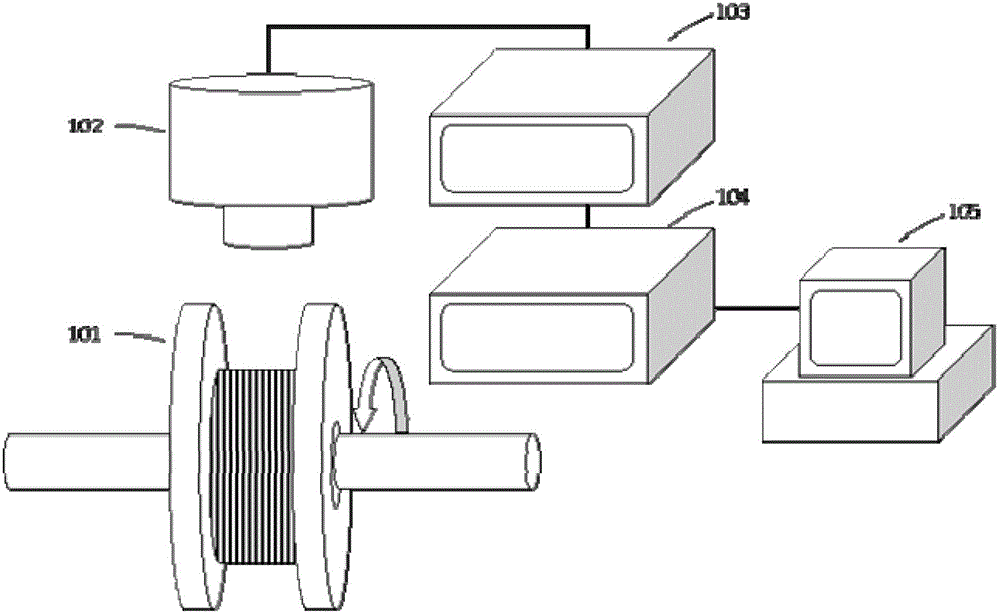

[0042] The device used in a method embodiment of the present invention is as figure 1 As shown, the device includes: a rotating mechanism for installing the fiber ring under test (not shown in the figure); an optical coherence tomography system, the probe of which is placed on the fiber ring under test for scanning the fiber ring, And collect the OCT information of the optical fiber ring; a computer is connected to the optical coherence tomography system to process the OCT information of the measured optical fiber ring and perform three-dimensional imaging on it. The image of the glue on the ring to judge the quality of the fiber ring.

[0043] The optical coherence tomography imaging system of the device in this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com