A Variable Nozzle Turbocharger Adjustment Mechanism Integrated on Turbine Housing

A technology of turbocharger and turbine casing, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problems of low exchange rate and versatility of parts, increased energy loss, stuck, etc., to improve parts Interchangeability and versatility, reducing motion resistance, preventing solder joint protrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the accompanying drawings and examples.

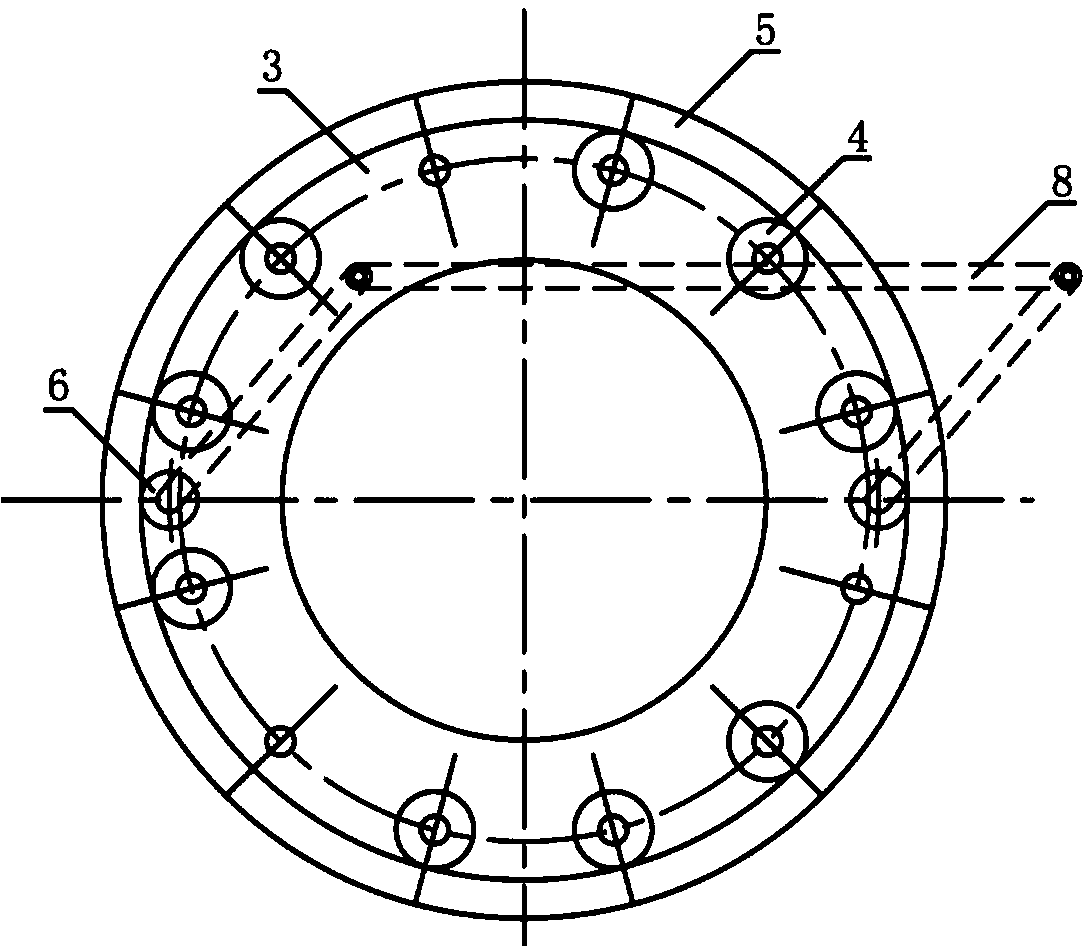

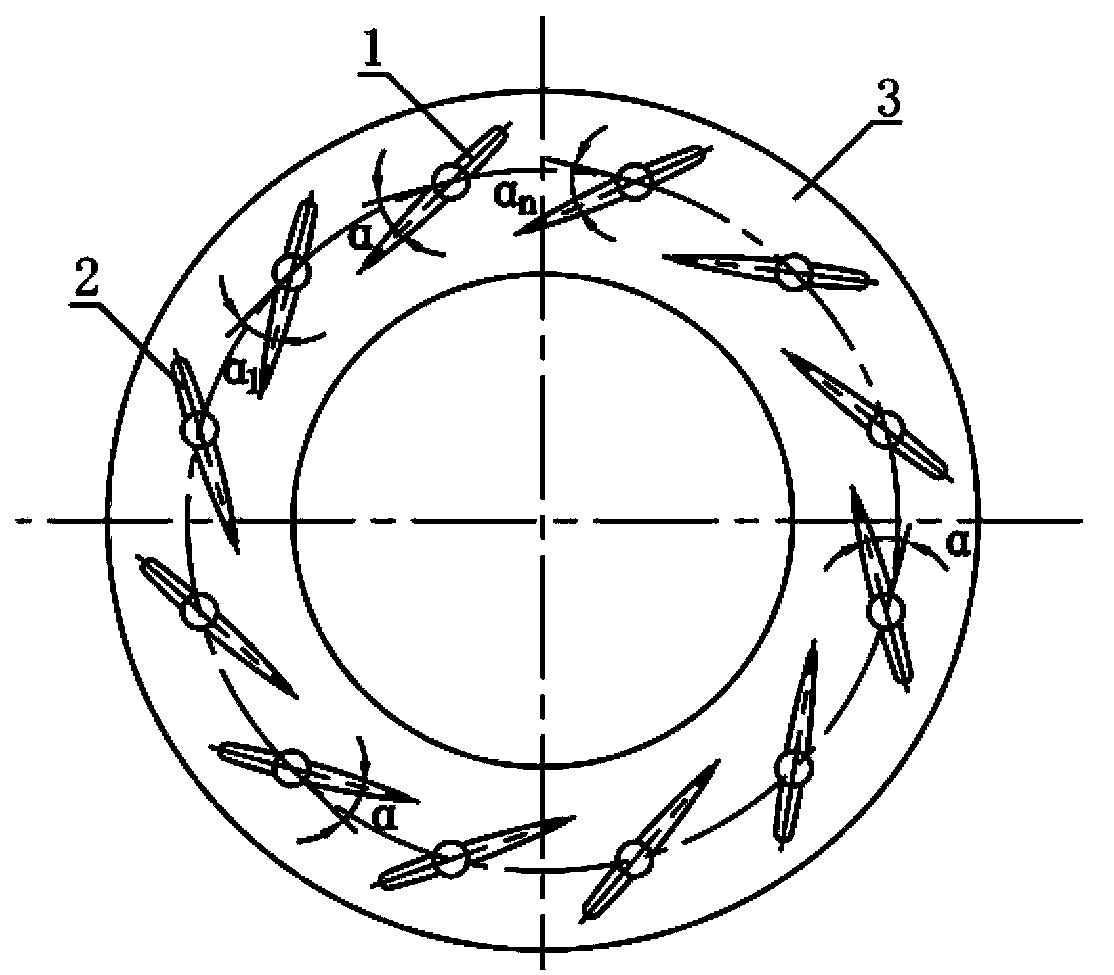

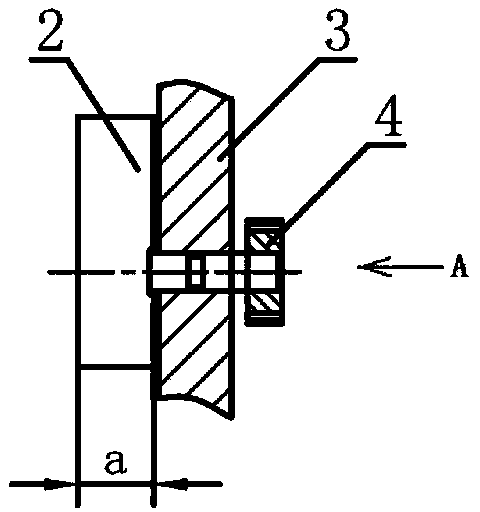

[0035] The present invention provides a variable nozzle turbocharger adjustment mechanism integrated on the turbine casing, the mechanism includes a nozzle ring adjustable blade drive device, three nozzle ring fixed blades 1, nine nozzle ring adjustable blades 2, Split type turbine casing 9 and turbine casing cover plate 10, the peripheral equipment is an intermediate body; as attached figure 1 and 2 As shown, the nozzle ring adjustable vane driving device includes a mounting plate 3, a driven gear 4, a driving ring gear 5, a driving gear 6, a driving gear shaft 7, and a double rocker driving mechanism 8; wherein, the mounting plate 3 is a circular structure ;

[0036] The three nozzle ring fixed vanes 1 are evenly distributed on the mounting plate with the same opening α, and the width of the nozzle ring fixed vanes 1 is used to control the width of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com