Caving coal hydraulic support with large swing beam structure

A hydraulic support and top-coal caving technology, which is applied in mine roof support, mining equipment, earthwork drilling, etc., can solve the problem of low top-coal recovery rate, achieve large coal discharge space, high coal discharge point, and safe working space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

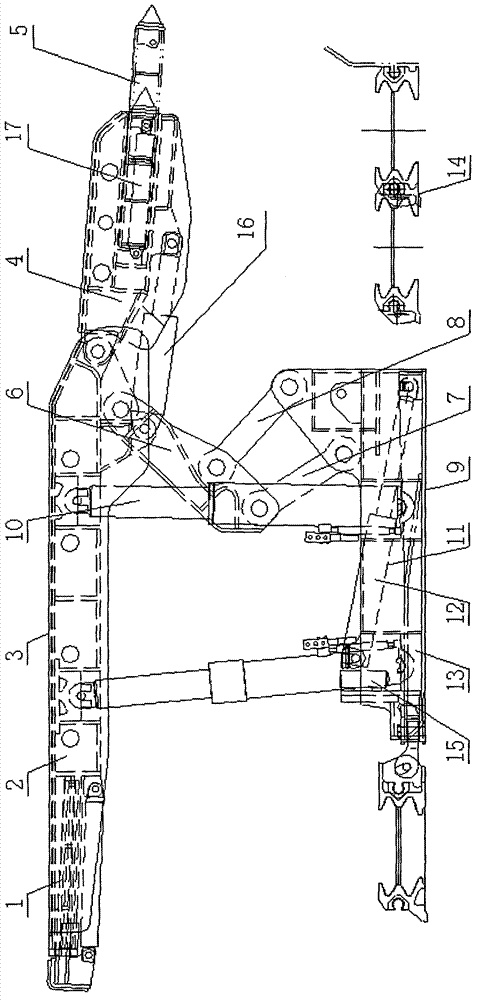

[0011] Embodiment one: if figure 1 As shown, a large swing beam structure top coal hydraulic support mainly consists of top beam 3, telescopic beam 1, cover beam 6, side guard plate 2, front connecting rod 7, rear connecting rod 8, base 9, and pushing mechanism 11 , a column 10, a jack and an operating valve; the specific structure is that the top beam 3 and the base 9 are connected through the column 10, the front end of the top beam 3 is provided with a telescopic beam 1, and the rear part of the top beam 3 is provided with a cover beam 6, The shield beam 6 is connected with the base 9 through the front connecting rod 7 and the rear connecting rod 8, and the base 9 is provided with a push mechanism 11, which is composed of a push cylinder 12 and a push rod 13, and the push mechanism 11 adopts an inverted structure, The push cylinder 12 is hinged with the base 9, the rear end of the push rod 13 is hinged with the push rod 13 of the push cylinder 12, and the hydraulic support ...

Embodiment 2

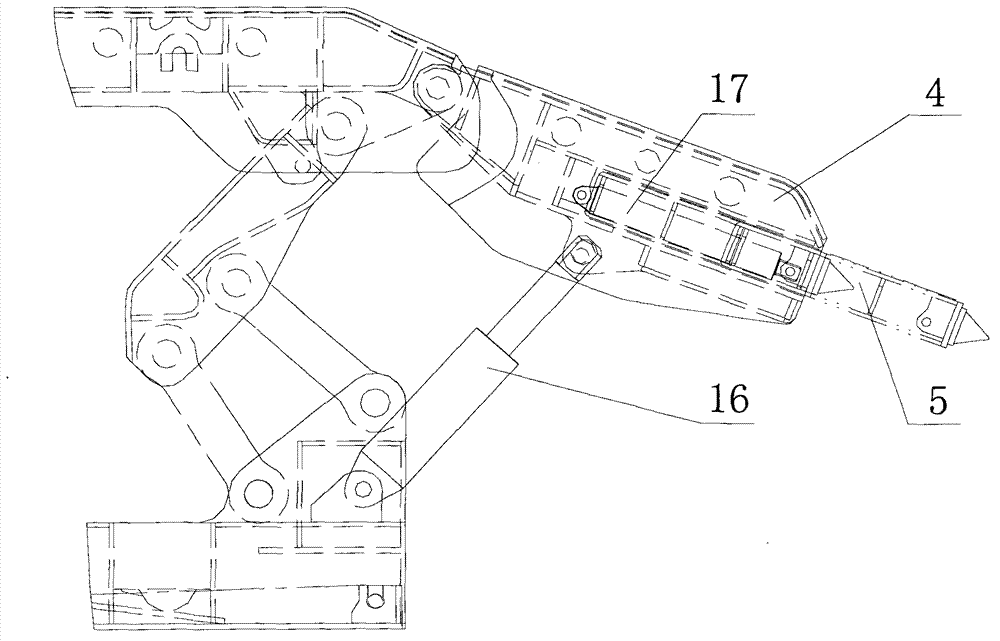

[0012] Embodiment two: if figure 2 As shown, a large swing beam structure top coal caving hydraulic support, the basic structure is basically the same as that of Embodiment 1, and will not be described again here, the difference is that the oil cylinder of the swing beam jack 16 is hinged on the base 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com