Port exhaust assembly used for ballastless track construction and track construction method

A ballastless track and construction method technology, applied in tracks, track laying, track maintenance, etc., can solve the problems of inability to discharge air in time, affecting project quality and operation safety, and insufficient compactness of cement emulsified asphalt mortar, and achieves an increase in The effect of large construction costs, improved quality and operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

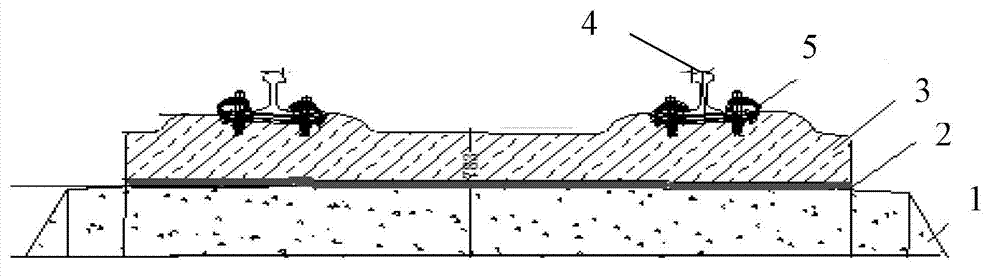

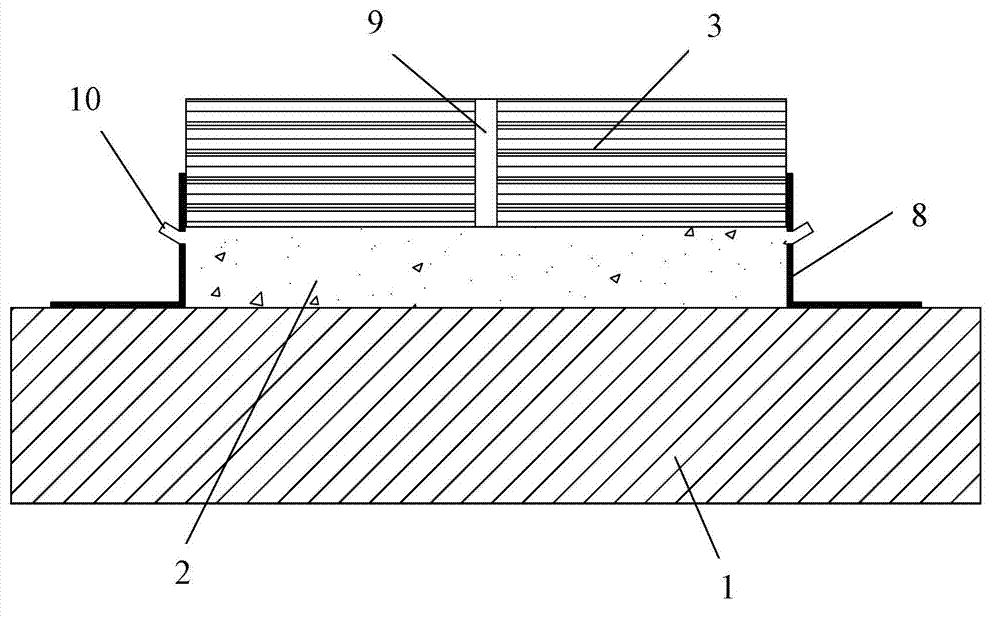

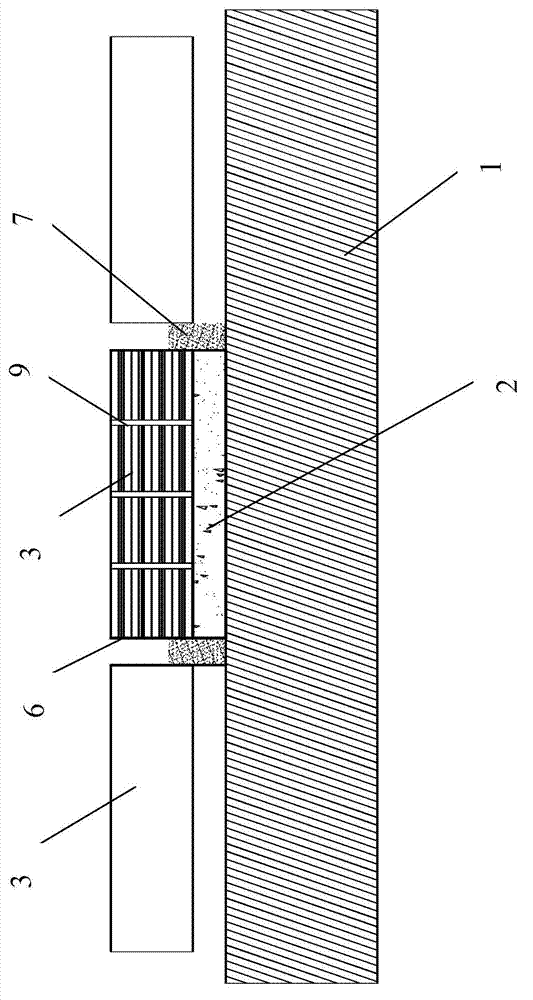

[0024] The port exhaust assembly for ballastless track construction and the track construction method provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Components that are the same as those in the prior art are assigned the same reference numerals, and their descriptions are omitted.

[0025] Such as Figure 3-Figure 6 and Figure 1-Figure 3 As shown, the port exhaust assembly for ballastless track construction provided by the present invention includes a plastic foam board 11 and a plurality of end exhaust pipes 12; wherein the plastic foam board 11 is arranged on the end face of the track plate 3 in a fitting manner, A plurality of openings 13 are recessed upwards at a distance from the lower end edge; one end of the end exhaust pipe 12 is an oblique opening, and an end exhaust pipe 12 is obliquely inserted in each opening 13 on the plastic foam board 11, and the end exhaust pipe 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com